Among the manifold ways to generate electricity from renewable sources, solar PV modules are believed to be one of the most efficient. Especially heterojunction solar cells have a low carbon footprint because of the sparing use of silicon in them and high efficiency levels in industrial production. During the production of heterojunction cells the element silver is used for busbars and contacts. Silver conducts the electricity that is generated in the silicon layer by means of solar radiation. This material is one of the most expensive components of a solar module. Also, the silver deposits available on this planet are limited. In view of the rising demand in solar panel production, this may pose a problem, especially as silver is needed in other sectors such as electromobility and the 5G technology too. One solution to this problem is the development of more advanced technologies to eliminate the use of silver in PV modules.

Now (2022), scientists at Fraunhofer Institute for Solar Energy Systems ISE have tackled this problem. A team of researchers there has developed an electroplating process for replacing silver with copper in the heterojunction solar panels. They chose copper because it is many times cheaper and more readily available than silver.

In order to protect the electrically-conductive surface of the solar cell from being electroplated with copper, the scientists in a first step masked the relevant areas. They covered these areas with a coating which had an insulating effect so that the copper layer would only build up in areas free from the insulation. The other important achievement was that they were able to replace the polymers usually employed for masking the wafer with aluminium. This material can be fully recycled and is cheaper than polymers.

The scientists found that replacing silver with copper even increased the conductivity of the device. The copper line has an extremely small width of 19 μm (micrometers) so that the light-absorbing silicon layer suffered from less shading than with the silver lines which also increased the electricity yield.

Using silver as a masking layer brought along its own set of problems as aluminium is electrically conductive. However, as aluminium can form an insulating oxide layer on its surface, the scientists used this particular oxide layer native to aluminium to render the material non-conductive. This was another great achievement of this research.

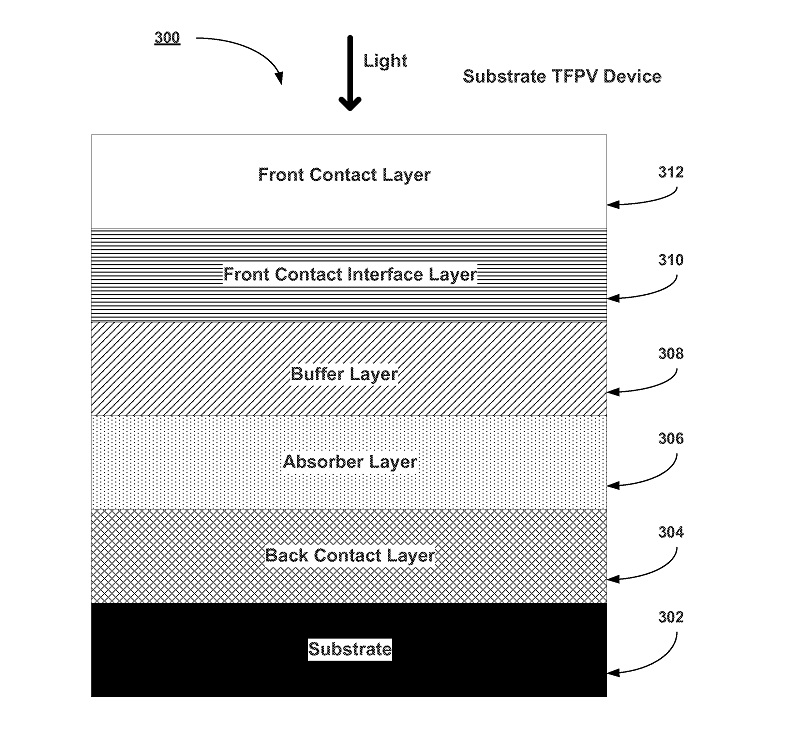

Improving efficiencies as well as production costs of solar cells has been a chief interest of scientists around the world for several years. In 2012, for example, scientists researched methods for forming copper-indium-gallium(sulfide)-selenide absorber layers in thin film photovoltaic devices with graded compositions and graded band gaps. They analysed several approached: one involving depositing a Cu-rich precursor layer followed by a Cu-poor precursor layer, another involving depositing a Cu-poor precursor layer followed by a Cu-rich precursor layer or depositing a Cu-poor precursor layer followed by a Cu-poor precursor layer. A fourth approach included depositing a Cu-rich precursor layer followed by removing excess Cu-chalcogenide using a wet etch, followed by a Cu-poor precursor layer. Also, Ag or Al, respectively, were used to increase the band gap at the front surface of the absorber layer.

Image: Substrate TFPV Device

Source: US20130164885A1

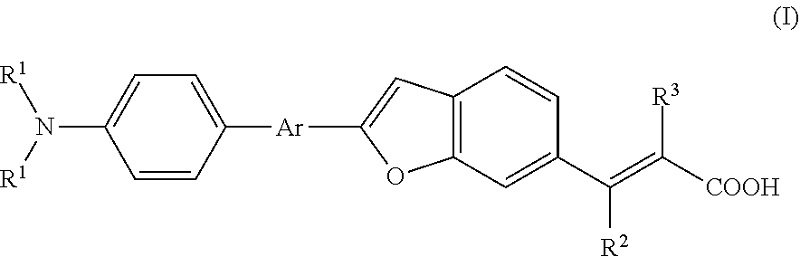

In 2022, scientists designed a dye and subsequently a dye-sensitized solar cell (DSSC) which was based on a semiconductor that is formed between a photo-sensitized anode and an electrode. The dye was composed of a compound of the formula I and its structural isomers:

Image: A compound of formula I

Source: US20220235021A1

Each R 1 was independently selected from the group consisting of substituted or unsubstituted linear or branched C - alkyl, substituted or unsubstituted phenyl, substituted or unsubstituted CcC12 aryl (including fused, bicyclic and tricyclic aryl), substituted or unsubstituted C4-C12 heteroaryl (including fused, bicyclic and tricyclic heteroaryl), substituted or unsubstituted C5-C10 cycloalkyl, and substituted or unsubstituted C5-C10 heterocycloalkyl compounds, -Ar- was a pi-bridge, and R2 and R3 were selected from the group consisting of H, -CN, ----COOH, -X, substituted or unsubstituted linear or branched C1 -C10 alkyl, ----COOR, - CONHR, -CON(H)OR, -SO3R, -SO2R---OSO3R, - PO3HR, and -OPO3HR; X is halogen; and R is substituted or unsubstituted linear or branched C1 -C10 alkyl.

There are several benefits to using copper and aluminium instead of silver and polymers in solar PV modules: Both copper and aluminum can integrate photovoltaic production much better in to the circular economy, improving environmental and social standards in the process. Both materials are much cheaper and readily-available in many parts of the world. The supply chains will be much shorter and the price less dependent on international raw material markets or foreign suppliers

To launch this technology onto the market more quickly, Fraunhofer ISE started the spin-off project PV2+. The letters “P” and “V” stand for photovoltaics, with “2+” indicating the double positive charge of copper ions in the electroplating bath. A pilot production plant together with industrial partners is planned for the start of 2023.

The researchers are convinced that their innovative solar cells are an important milestone in achieving a power supply based on renewables. Because of its beneficial characteristics the solar cell has the potential to quickly gain a foothold in the market. The project is funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) as part of its start-up program Exist.