Aenert. Research Laboratory news

For more than four decades now, the energy of the sun has been used to power devices of everyday life. To improve the efficiency of the cells, scientists are making great effort to create different materials and structures. One such material, for example, is comprised of a compound of elements, which is often arranged into a cubic structure and called perovskites.

Perovskite solar cells are counted among the alternative methods of harnessing solar energy which are not yet marketable. They consist of various layers sequentially deposited onto a conductive glass substrate requiring several coatings to create the necessary full device structure.

Perovskite cells are made of a perovskite light-absorbing layer and adjacent layers able to extract positive and negative charges on opposite sides of the perovskite when light is absorbed. One of these layers, the hole-transport layer (HTL), can extract positive charges. Perovskites can be made without an HTL, but the efficiency of such devices is behind that of full perovskite solar cell device structures.

Now (2023), scientists at the National Renewable Energy Laboratory (NREL) have developed a concept which simplifies the process of perovskite solar cell manufacture and could accelerate the commercialization of the technology. The team of scientists designed a high-efficiency solar cell which retained more than 90% of the initial efficiency after 1,200 hours of continuous operation.

Image: Molecular doping enabled scalable blading of efficient hole-transport-layer-free perovskite solar cells

Source: Wu-Qiang Wu, Qi Wang, Yanjun Fang, Yuchuan Shao, Shi Tang, Yehao Deng, Haidong Lu, Ye Liu, Tao Li, Zhibin Yang, Alexei Gruverman, Jinsong Huang/ Molecular doping enabled scalable blading of efficient hole-transport-layer-free perovskite solar cells/ Nature Communications volume 9, Article number: 1625 (2018), 24 April 2018/ doi.org/10.1038/s41467-018-04028-8/ Open Access This is an Open Access article is distributed under the terms of the Attribution 4.0 International (CC BY 4.0)

This was achieved using a one-step solution-coating procedure which enabled forming of two separate layers of a solar cell - the HTL and perovskite absorber - with only one coating step. This eliminated the separate hole-transport layer fabrication. The chemical solutions formed “a robust self-assembled monolayer simultaneously as an excellent hole-selective contact while the perovskite crystallizes.”

The concept was proved at NREL, but other groups expanded this finding to be more universal with different perovskite compositions, HTLs, different solvents and various other coating styles. This will help for this work to gain greater adoption.

Improving the makeup of perovskites and making them deployable on an industrial scale has long been one of the chief interests of science and industry around the world. In 2018, scientists designed hole-transport-layer-free PSCs with improved photovoltaic performance by simplifying the device architecture via a scalable doctor-blading process. Molecular doping of halide perovskite films was responsible for improved conductivity of the films and their electronic contact with the conductive substrate. This resulted in a reduced series resistance and enabled extraction of photoexcited holes from perovskite directly to the conductive substrate. The bladed hole-transport-layer-free PSCs exhibited a stabilized power conversion efficiency above 20.0%.

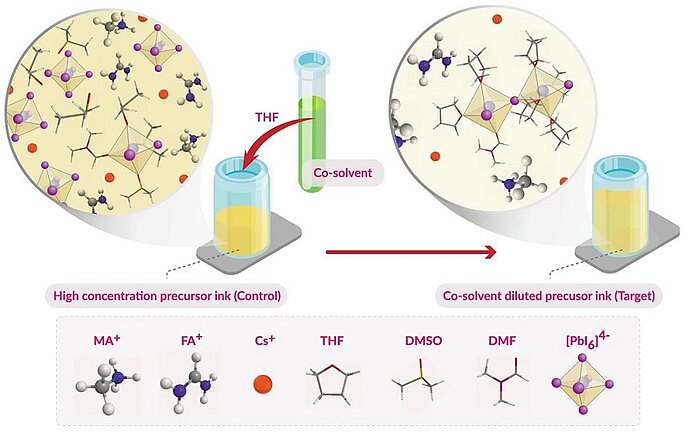

Image: Schematic illustration of the co-solvent dilution strategy for perovskite deposition

Source: Hong Zhang, Kasra Darabi, Narges Yaghoobi Nia, Anurag Krishna, Paramvir Ahlawat, Boyu Guo, Masaud Hassan S. Almalki, Tzu-Sen Su, Dan Ren, Viacheslav Bolnykh, Luigi Angelo Castriotta, Mahmoud Zendehdel, Linfeng Pan, Sandy Sanchez Alonso, Ruipeng Li, Shaik M. Zakeeruddin, Anders Hagfeldt, Ursula Rothlisberger, Aldo Di Carlo, Aram Amassian/ A universal co-solvent dilution strategy enables facile and cost-effective fabrication of perovskite photovoltaics/ Nature Communications volume 13, Article number: 89 (2022), 10 January 2022/ https://doi.org/10.1038/s41467-021-27740-4/ Open Access This is an Open Access article is distributed under the terms of the Attribution 4.0 International (CC BY 4.0)

In 2022, scientists developed an efficient strategy for eco-friendly and cost-effective fabrication of highly efficient perovskite solar cells. To achieve this, a high volatility co-solvent was used, which could dilute perovskite precursors to a lower concentration (<0.5 M) while retaining similar film quality and device performance as a high concentration (>1.4 M) solution. Mechanistic insights showed that an ultra-rapid evaporation of the co-solvent took place together with beneficial alteration of the precursor colloidal chemistry upon dilution with co-solvent. This was confirmed by in-situ studies and theoretical simulations. The co-solvent tuned precursor colloidal properties were also responsible for enhanced stability of the precursor solution, which extends its processing window and minimises the waste. This strategy was found to be universally successful across different perovskite compositions, and scales from small to large-scale modules and used an industrial spin-coating, which might make the lab-to-fab translation of perovskite technologies easier.

There are several advantages to the new coating technique: The simplified process to make the HTL and perovskite reduces the number of coating and heating steps and removes the need for expensive HTL materials. This was all the more beneficial as it is challenging to uniformly manufacture a thin HTL layer using the scalable solution method. Removing the steps previously needed to create the HTL and then having to heat it up could cut the solution-processing time by a third. This could revolutionise the manufacturing process as a whole as multiple processing steps could be combined; layers could spontaneously form.

So far, standardised validation of perovskite solar cells has proved difficult because of the changing structures of perovskite compositions. Also, there is not enough field data on perovskite performance to enable valid comparisons. There is hope that this new technology will enable a more standardised approach to manufacturing, thus creating more reliable data.

By the Editorial Board