Petroleum fuel still remains the main energy source for an extensive list of consumers' sectors, primarily including transport and heating, but in a number of countries – also electric energy production. Despite the fact that the share of renewable energy sources in overall end-use energy consumption keeps growing steadily, in the coming two-three decades fossil fuel will continue to play a key role in the global energy balance. This situation is aggravated by a noticeable depletion of light oil reserves and an ever-growing involvement of its heavy grades into circulation. Efficient extraction of such oil requires unconventional approaches based on Enhanced Oil Recovery (EOR) methods. In particular, water flooding or gas injection technologies became widespread, including in combination with additional chemical activators. Such techniques as, for instance, carbon dioxide injection, polymer flooding, water flooding involving surface-active agents, and other technological variants are particularly attractive.

The use of CO2 to increase oil recovery rate is pretty widespread in production practices, particularly in the USA. Carbon dioxide is miscible with crude oil, it ensures reduction in the oil viscosity, which is the most critical aspect of heavy oil production. In many scenarios the use of CO2 is less expensive than other chemical substances and gases used in Enhanced Oil Recovery (EOR) operations. During the polymer flooding, polymer-augmented water is injected into an oil formation. Inasmuch as such polymers consist of long-chain molecules with high molecular weight, they allow to increase the viscosity of water. In its turn, it increases oil production rates by decreasing the water/oil mobility ratio. Water flooding involving surface-active agents (surfactants) is a well proven method of oil recovery increase, and its use is considerably expanding, including the cases of heavy oil production. Surfactants ensure the lowering of interfacial tension, improve the wettability of porous rocks, increase water mobility. This allows larger volumes of oil to be displaced in complex reservoirs.

A significant part of effective technical solutions aimed at the development of these technologies is concentrated in patent documents registered with various patent offices. The patent database "UNCONVETIONAL OIL PRODUCTION. Gas injection or water flooding" was prepared by EnerTechUp company and includes the inventions, where the authors disclosed technical solutions based on the introduction of various activators into hydrocarbon layers and includes more than eight thousand patent documents published in 1995-2022.

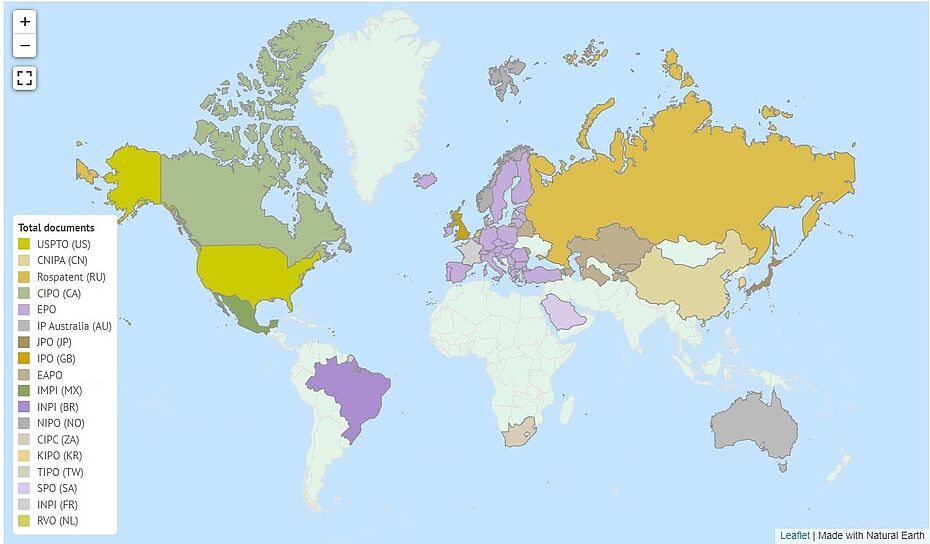

In the last 20-year period patents were granted in 30 patent offices around the world. The most popular patent offices with applicants were CNIPA (China), USPTO (US), Rospatent (RU), CIPO (CA), EPO, and IP Australia (AU). In recent 5 years the largest share of registered patent applications was in CNIPA (China), and a considerable increase in patenting activity was seen in INPI (BR).

Patent offices participating in the patenting process (granted 5 or more patents in 2002-2021)

Source: www.aenert.com

Representatives of 44 countries around the world participated in the patenting process. About 50% of patents were granted to US applicants. The share of Saudi Arabia residents has grown substantially in applicants who registered their applications in the last five years.

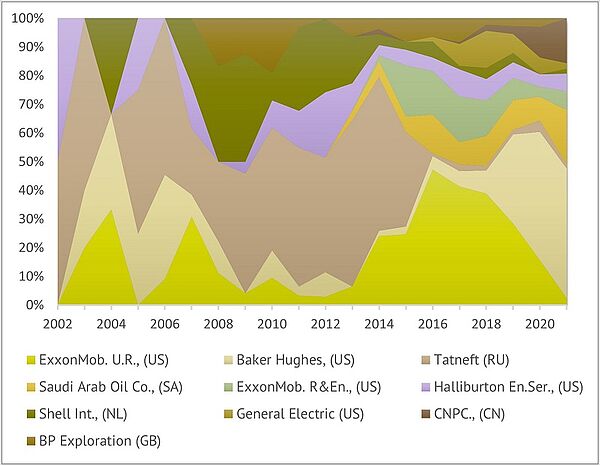

1596 applicants from 44 countries participated in the preparation of the inventions. ExxonMobil Upstream Research Company (US), Baker Hughes Incorporated (US), Tatneft (RU), Saudi Arabian Oil Company (SA), and ExxonMobil Research and Engineering Company (US) were each granted more than 100 patents for the 20- year period. Baker Hughes Incorporated (US), Saudi Arabian Oil Company (SA), PetroChina Company Limited (CN), and ExxonMobil Upstream Research Company (US) were leading by the number of registered patent applications during the last five years.

The list of top 10 most productive applicants by the number of patents includes:

ExxonMobil Upstream Research Company (US)

Baker Hughes Incorporated (US)

Tatneft (RU)

Saudi Arabian Oil Company (SA)

ExxonMobil Research and Engineering Company (US)

Halliburton Energy Services, Inc. (US)

Shell Internationale Research Maatschappij B.V. (NL)

General Electric (US)

CNPC China National Petroleum Corporation (CN)

BP Exploration (GB)

Top 10 applicants (trends). Patents, 2002-2021

Source: www.aenert.com

Devices and methods were mentioned most of all in the patented inventions. Methods prevailed among patent applications in the last five years. IPC indices E21B43/20 (displacing by water), E21B43/16 (enhanced recovery methods for obtaining hydrocarbons); E21B43/22 (use of chemicals or bacterial activity); and E21B43/24 (using heat, e.g. steam injection) were assigned to patents more than others.

As examples, the following groups of inventions were additionally considered: Carbon dioxide injection; Polymer flooding; Water flooding using surfactants.

Example of technical solutions:

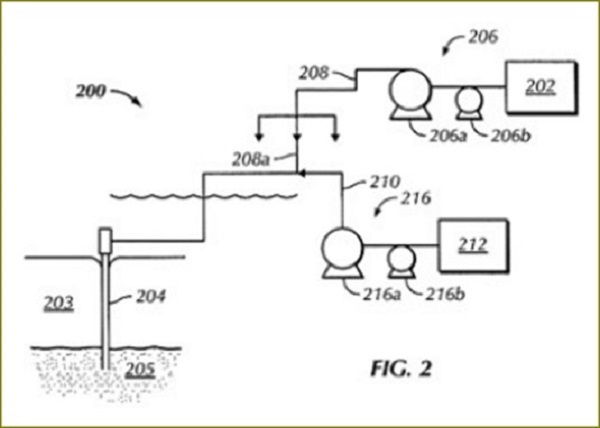

Polymer gels as flow improvers in water injection systems / P: US9903169B2 / IPC: E21B21/06, B01F3/12, E21B43/20, C09K8/588, C02F1/68, F17D1/17, C02F1/56 / Eikaas Torbjorn Tenold, Solbakken Jan Erik, Sunde Egil / Schlumberger Norge As, Statoil Asa / Appl. date: 17/09/2009; Publ. date: 27/02/2018 / United States Patent and Trademark Office

The invention discloses a water injection system to be used, for instance, in a polymer flooding for enhanced oil recovery operations. According to the claims of the invention, the system includes pumping an injection fluid, and improving its flow by pumping a polymer gel, which “...contains a percent by weight of polymer that ranges from about 5 to 20 percent”, “...has a viscosity of at least about 50,000 cP”, has a concentration ranging from 5 to 120 ppm, and includes a polymer with a molecular weight from 6,000,000 to about 20,000,000. The polymer is pumped at substantially the same pressure as the injection fluid, which is from 200 to 320 bar. The invention aims to resolve the drawbacks of prior art technologies, such as “…limitations on the pumping capacity and the energy expelled for injecting water into a producing reservoir”.

Image from US9903169B2

Along with “Gas injection or water flooding”, Technology elements “Steam injection”, and “Chemical stimulation” also prevailed. Such problems as “Low efficiency of primary production”, “Environmental balance and protection”, and “High running costs of repair and replacement” were frequently mentioned in patents and patent applications.

Over the 20-year period the cumulative patenting activity has grown substantially. Starting with 2016 more than four hundred new patent applications have been registered annually, and from 2015 more than one hundred fifty patents have been granted every year.

A complete version of the database can be found at www.aenert.com