The thin-film solar cell is a device which converts light into electrical energy and is made up of layers of a photon-absorbing material deposited over a flexible substrate. Thin-film solar cells were originally developed in the 1970s and have improved over the years so that now the global thin-film solar cell market is growing at an unprecedented rate.

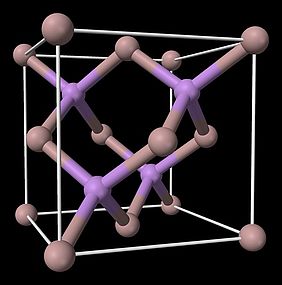

Gallium arsenide (GaAs) is a commonly used III-V semiconductor compound for photovoltaic applications. It has high electron mobility, a direct bandgap and easily adaptable growth mechanisms. GaAs single junction devices reach an overall efficiency close to 30%. The only drawback concerning gallium arsenide solar cells is that their production is rather expensive. Now (2019), scientists at the National Renewable Energy Laboratory (NREL) have discovered a method of producing gallium arsenide (GaAs) thin-film solar cells cheaply by reusing the surface on which the cells are made. The scientists created a 14.44%-efficient GaAs solar cell formed on a layer of reformed porous germanium. For this purpose, a thin germanium layer was put on top of a germanium wafer on which the solar cell was then grown by means of a novel germanium-on-nothing (GON) approach. In this process, a series of cylindrical pores was created in the germanium wafer. Due to the ratio of the pores’ diameter to depth and the distance between the pores, a void formed between the suspended single-crystal layer of germanium and the surface of the germanium wafer. The GaAs cell and the thin layer of germanium could thus be easily peeled off of the substrate so that the original germanium wafer could be reused.

This method of fabricating a GaAs thin-film solar cell is the result of a long history of research. In 2010, scientists developed a way of producing microchips of a compound semiconductor made of gallium arsenide (GaAs). They grew stacks of layers of GaAs alternating with aluminium arsenide (AlAs). When the stack was complete, the AlAs layers were etched away using hydrofluoric acid, leaving the films of GaAs, which were then peeled off and stamped onto another substrate such as glass, silicon, or plastic.

In 2014, a high-performance solar cell with a conversion efficiency of 10.4% for a doped graphene/GaAs structure was designed. By means of an anti-reflection technique, conversion efficiency was further improved up to 15.5%, which was higher than any other conversion efficiency for a graphene/Si system at that time. The solar cell was composed of a GaAs substrate, graphene and electrodes. A SiNx film was put between graphene and GaAs as the dielectric insulating layer. The GaAs substrate was heavily n-type doped and had a resistivity of between 0.01-0.1 Ω/cm.

In 2016, scientists developed a GaAs thin-film solar cell formed on a flexible substrate by means of a simple and fast epitaxial lift-off method. To realize a highly efficient thin film solar cell, an HF-resistant AuBe/Pt/Au metal combination was used as a new p-type ohmic contact, by which an n (emitter)-on-p (base) single-junction GaAs thin-film solar cell was fabricated. The single-junction GaAs thin-film solar cell on a flexible substrate was made using the standard solar cell fabrication process.

Solar cells made from elements such as gallium and arsenic are extremely efficient at converting sunlight into energy. Their greatest drawback, however, is that the costs involved are high. Thus, their use has been limited to niche applications, mainly in the aerospace industry. The substrate itself, which is the crystalline wafer on which the cells are grown, accounts for about 30% of the cost of a III-V solar cell.

Thin-film solar cells have continued to improve in efficiency over the past decades and may one day even replace the classic inflexible photovoltaic technologies that have been in use since the mid-20th century. Sheets of thin films could be used to generate electricity in places where other photovoltaic cells cannot be applied, such as on curved surfaces on buildings or cars or even on clothing to charge handheld devices, which might help achieve a sustainable energy future. The new method of creating gallium arsenide solar cells might have overcome the greatest challenge involved in their production – the costs – and demonstrated that rare earth materials can be suitable for large-scale industrial production.