Unravelling the atomic structure of different materials is usually a difficult process which leaves a lot of questions unanswered when it comes to analysing the X-ray data. However, this process has recently become much easier as a new approach combines high-powered X-ray beams with advanced computing methodologies.

Scientists at Argonne National Laboratory (2022) have designed a new technique which can make the analysis of material structures from patterns gained from X-ray experiments more efficient and quicker.

The technique they used which is called AutoPhaseNN was based on machine learning. An algorithm was trained on select experimental data and then used to choose the most likely result of the experiment. The data for the experiments was collected by means of analysing ultrabright X-ray beams from Argonne’s Advanced Photon Source (APS) where the light was captured while bouncing off a material in a process called diffraction.

AutoPhaseNN belongs to the category of unsupervised machine learning where the computer algorithm learns independently how to do a computation more accurately and efficiently. This means that labeled solutions with ready results are not used to train the computer, a process which usually involves human intervention.

In order to get information about the material structure, a scientist collected and analysed the information pertaining not only to the amplitude of the diffracted signal, but also its phase. However, the amplitude, or intensity, was not the only part which can be measured. Since the X-ray beams used to illuminate the sample were coherent with the same initial phase, every phase change occurring as a result of the diffraction could be mapped back to the sample itself.

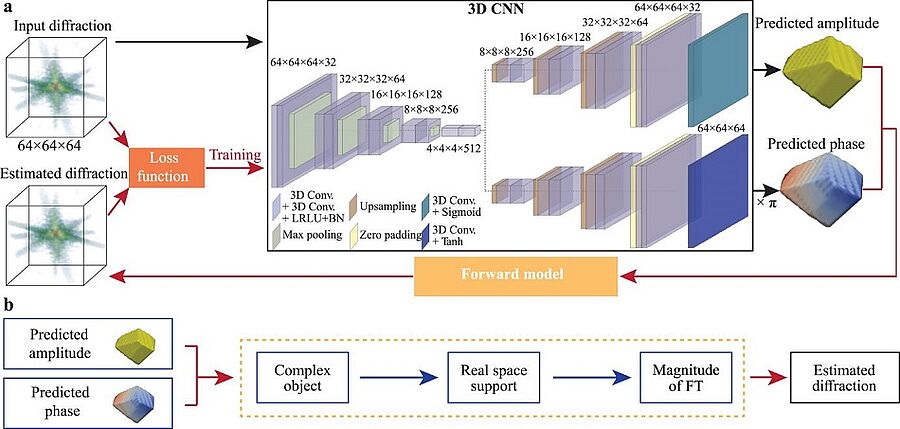

By incorporating the imaging physics into the deep learning model during training, AutoPhaseNN was able to learn to invert 3D BCDI (Bragg coherent X-ray diffraction imaging) data in a single shot without being shown real space images. Once trained, AutoPhaseNN was shown to perform the 3D BCDI data inversion about 100 times faster than iterative phase retrieval methods and provide comparable image quality. In conventional, supervised neural networks, the researchers would have had to combine incomplete information with fully assembled examples so that the neural network could have something to train against. Using an unsupervised neural network instead, the algorithm could learn to assemble the puzzle from the incomplete pieces. The network that resulted from this experiment was fast, accurate and could provide 3D images in real time to scientific users of facilities like the APS.

Image: Schematic of the neural network structure of AutoPhaseNN model during training

Source: Yudong Yao, Henry Chan, Subramanian Sankaranarayanan, Prasanna Balaprakash, Ross J. Harder and Mathew J. Cherukara/ AutoPhaseNN: unsupervised physics-aware deep learning of 3D nanoscale Bragg coherent diffraction imaging/ npj Computational Materials volume 8, Article number: 124 (2022), 03 June 2022/ doi.org/10.1038/s41524-022-00803-w/ Open Source This is an Open Access article is distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0)

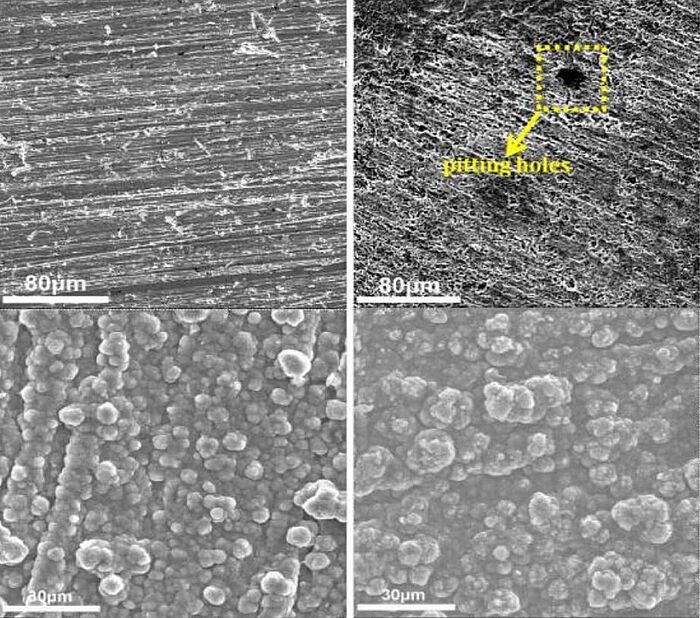

For many years scientists have tried to get a better understanding of the nature of battery failure. In 2020, polypyrrole (PPy) coatings doped with oxalic acid were electrodeposited by cyclic voltammetry technique in order to enhance the corrosion resistance of a copper current collector. The electrochemical degradation of the polypyrrole-coated copper was analysed using electrochemical impedance spectroscopy (EIS) at room temperature in an organic electrolyte of lithium-ion batteries. After exposure to the electrolyte for up to 500 h, the charge transfer resistance (Rt) of the polypyrrole-coated copper was much improved and greater than that of the bare copper. This showed that polypyrrole coatings could enhance the corrosion resistance of copper current collectors.

Image: Surface morphology of the bare copper and the as-deposited PPy coating before and after immersion in the electrolyte for 500 h

Source: Xueao Jiang/ Corrosion Protection of Copper Current Collector Of Lithium- Ion Batteries by Doped Polypyrrole Coatings/ International Journal of Electrochemical Science, March 2020/ DOI:10.20964/2020.03.15/ Open Source This is an Open Access article is distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0)

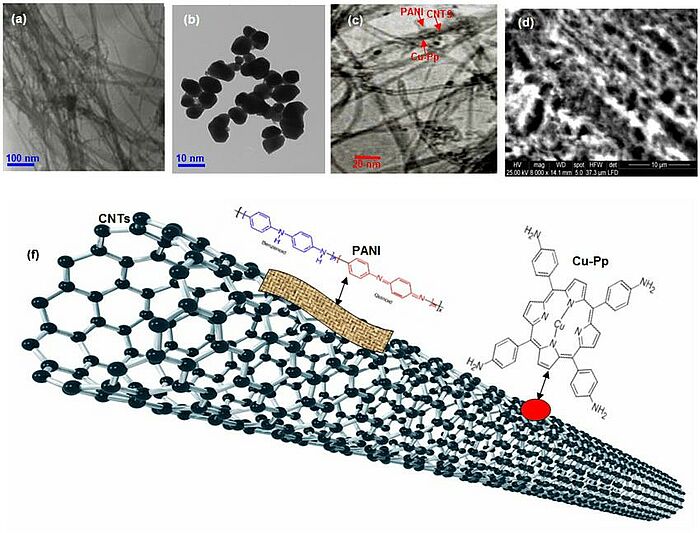

In 2021, scientists researched the development of a new nanocomposite coating which was able to conserve the Pb plate properties in an acidic battery electrolyte. This composite consisted of a polyaniline conductive polymer, Cu-Porphyrin and carbon nanotubes (PANI/Cu-Pp/CNTs). The structure and morphology of the PANI/Cu-Pp/CNTs composite were analysed with the help of transmission electron microscopy (TEM), scanning electron microscopy (SEM) and X-ray diffraction (XRD) analysis. In view of the H2 gas evolution measurements and Tafels curves, the coated Pb (PANI/Cu-Pp/CNTs) was shown to be highly resistant against the liberation of hydrogen gas and corrosion. Electrochemical impedance spectroscopy (EIS) results also proved the suppression of the H2 gas evolution by using coated Pb (PANI/Cu-Pp/CNTs). The coated Pb (PANI/Cu-Pp/CNTs) enhanced the cycle performance of lead-acid battery as opposed to the Pb electrode with no composite.

Image: (a) TEM image of CNTs, (b) TEM image of Cu-Pp, (c) TEM image of PANI/Cu-Pp/CNTs composite, (d) SEM image of PANI/Cu-Pp/CNTs composite, and (f) The illustration of PANI/Cu-Pp/CNTs composite

Source: M. A. Deyab, Mohsen Qhatani/ Controlling the corrosion and hydrogen gas liberation inside lead-acid battery via PANI/Cu-Pp/CNTs nanocomposite coating/ Scientific Reports 11(1):9507, May 2021/ DOI:10.1038/s41598-021-88972-4/ Open Source This is an Open Access article is distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0)

There are several advantages involved in using the AutoPhaseNN algorithm: First and foremost, it is able to solve inverse problems by going from the pieces of the puzzle to create the puzzle itself. In this research, the scientists were making a set of observations and trying to identify the conditions that created them. This means that they did not solve the puzzle by iterating the process of trial and revision based on the prior knowledge, but let the algorithm learn from the incomplete pieces in a single step. They also performed phase retrieval as it is vital for understanding the structure and finding the most relevant information.

Alongside the new APS, new techniques of data analysis will have to be developed as more data will be collected more rapidly which in turn will require faster means of data processing. Advanced machine learning solutions will play an important role in this process, not only at Argonne lab but also at similar facilities around the globe.