Aenert news. Energy Exhibitions & Conferences

Out of the dense schedule of energy events in April 2023, we have selected only three due to the limited format of our review. However, in our opinion these are very meaningful, interesting and useful events that will contribute to reducing tensions in today's energy market.

11th Annual European Algae Industry Summit 2023, 19-20 April, Lisbon, Portugal, will discuss various aspects of algae production and application. Among them are Market Overview of Industry Trends & Drivers; Algae Foods; Managing EU Regulations across the Industry; Enhancing Algae's Reputation as a Sustainable Alternative; Adapting Approaches to Production in an Ever-Expanding Market. In terms of energy, Prospects for Algae Biofuel will be of obvious interest here. These products are sometimes seen as third-generation biofuels and the most promising area of renewable energy.

Summit participants will include algae producers & cultivation plant owners and operators, algae end market users, leading algae/biomass research institutes, technology providers for cultivation, plant engineers and constructors, green energy & biotech investors, green energy/biotechnology investors, venture capitalists, private equity firms etc. looking to invest in new & emerging markets, regulators & governments.

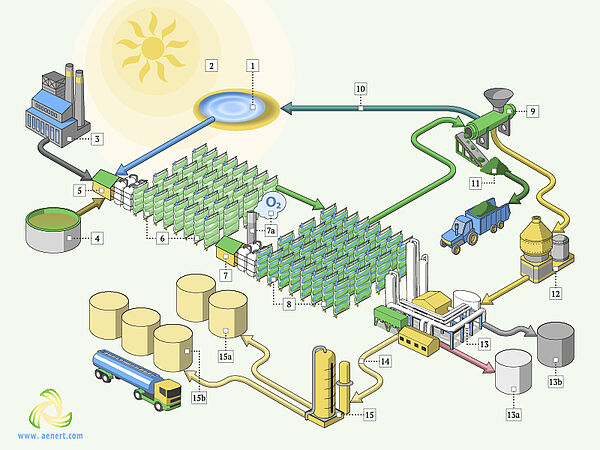

Algal biofuel production scheme

1. Water 2. Sunlight for algae growth 3. Facility emitting carbon dioxide 4. Nutrients 5. Gas, water and nutrient conditioning unit or incubation tank 6. Bioreactor network(microalgae ponds) 7. Second conditioning unit 7a. Oxygen 8. Algae harvesting reactors 9. Screw process unit 10. Recycled water 11. Algae biomass 12. Algae hexane solvent mixer 13. Transesterification unit 13a. Sodium hydroxide 13b. Methanol 14. Fuel conditioning 15. Biodiesel fuel combined with a glycerol 15a. Glycerol 15b. Algae biodiesel

Interestingly, the main sponsor of this event is the German company Schott, which is widely known in the modern energy industry and in particular as one of the main suppliers of high-purity glass receivers for concentrated solar power plants with parabolic trough technology.

The effective cultivation of microalgae for subsequent production of biofuel requires light, water, carbon dioxide, special mineral salts in strictly dosed proportions and the mixture must be continuously stirred. The technologies used for cultivation include open ponds and enclosed photobioreactios. However, many researchers prefer the open ponds solution. Unfortunately, production of biofuel from algae on an industrial scale has not yet been established. Technological problems have proven to be quite challenging.

Perhaps this summit will provide new ideas and technological methods to overcome the existing barriers.

The next annual exhibition and conference Wind Europe 2023, which will be held in Copenhagen from April 25 to 27, traditionally arouses great interest among specialists, investors and representatives of state authorities. This year about 500 exhibitors and more than 10000 participants are expected there. Over 50 sessions will be held with more than 250 speakers. Current issues of the wind energy industry, including the supply chain, obtaining licenses, grid connection, resource assessment, financing and many others will be presented to the public. Leading wind turbine manufacturers, including Vestas, GE renewable Energy, NordexAcciona, Siemens Gamesa and Enercon, have confirmed their participation.

Today wind power is a dynamically developing industry whose share in the total world energy production has reached about 7%. Ten years ago this share did not exceed 2%. The growth of power generation from wind turbines has more than quadrupled during this decade. In addition, wind power generates more than 50% of electricity relative to all renewable sources. According to GWEC, in 2022 the installed capacity of wind turbines in the world increased by another 78GW and reached 906 GW. In this case, the authors predict that, starting in 2023, the annual increase in new capacity in the world will be at least 100 GW. The wind industry in Europe will take a significant place in this process. Thus, according to BP Statistical Review of World Energy 2022, the share of European power generation in 2021 was 27%, with Germany, the UK and Spain making the most significant contributions.

The main indicators of wind energy in 2021

| Region/Country | Capacity 2021, GW | Generation 2021, TWh | Capacity factor, % |

|---|---|---|---|

| World | 824.9 | 1861.9 | 25.77 |

| Europa | 232.1 | 503.0 | 24.74 |

| Asia Pacific | 394.2 | 779.2 | 22.56 |

| N.America | 154.7 | 383.6 | 28.31 |

| China | 329.0 | 655.6 | 22.75 |

| USA | 132.7 | 383.6 | 33.00 |

| Germany | 63.8 | 117.7 | 21.06 |

| UK | 27.1 | 64.5 | 27.17 |

| Spain | 27.5 | 62.4 | 25.90 |

| France | 18.7 | 37.0 | 22.59 |

| Sweden | 12.1 | 27.3 | 25.76 |

| Denmark | 7.0 | 16.0 | 26.09 |

Based on BP Statistical Review of World Energy 2022

However, the past year 2022 was a year of increasing challenges in the wind industry and especially in Europe. First of all, it is necessary to mention the disappointing financial results of last year. Thus, the leading European manufacturers of wind turbines – Vestas and Siemens Gamesa finished the year 2022 with considerable losses. To a great extent, it is associated with the disruption of established stable supply chains due to the effects of COVID-19 and military actions in Ukraine. This inevitably affected the timing and quality of production. At the same time, competition in the market has intensified significantly from Chinese companies, which have multiplied their fleet of wind turbines in China and noticeably expanded their presence in the world. While in 2017 the share of wind turbine capacity installed in Europe was more than 33% relative to the global total, in 2021 it has dropped to 27%. On the other hand, the share of China's installed capacity in the world in 2021 increased to 40%, compared with 32% in 2017. But the most critical issue for the development of the wind industry is the increase of Capacity factor, which today in the world average is hardly more than 25% (see table). This problem can be solved mainly in three ways: by placing wind farms in offshore areas with high wind speeds, by increasing the tower height and rotor diameter of wind turbines and, finally, by equipping wind farms with energy storage systems. In Europe, successes in this matter have been achieved in the UK and Denmark, where there are excellent conditions for the placement of wind farms in offshore areas and where the stable operation time of wind turbines reaches 90%.

As for the production of wind turbines of higher power, until recently the Haliade-X produced by GE renewable Energy with the height of 107 meters and a rotor diameter of 220 meters caused real excitement, because it had a capacity of up to 14 MW and capacity factor of 63%. However, today Chinese companies build wind turbines with capacity of 17-18 MW and rotor diameter of over 250 meters. It is obvious that capacity factor of such a design will not be less than that of the Haliade-X. In December 2022 Vestas installed its latest V236-15.0 MW™ turbine at the Danish Østerild National test center for full validation, which will seriously compete with other manufacturers. However, this wind turbine will obviously not appear on the market until late 2023. In the meantime, the V164-10 MW™ turbine with much more modest specifications has been launched onto the market. Similar turbines developed by Siemens Gamesa – SG 14-236 DD and SG 14-222 DD will enter serial production only in 2024. Other European manufacturers do not have turbines of this capacity in their product lines.

The most problematic sector for renewable energy is large-scale storage. Certainly, there is evidence that storage systems at wind farms are increasing, but these volumes are still small, and the storage systems themselves are still expensive. The results of hybrid systems combining wind farms and pump-hydro accumulation station also look rather modest.

Due to the free exchange of opinions and demonstration of the latest technological achievements, the upcoming event in Copenhagen has all the potential to have a significant impact on solving the existing problems of the industry and to contribute to its development.

JEC World 2023 (April 25-27, 2023, PARIS-NORD VILLEPINTE), dedicated to composites, is a rather rare but very important event for today's renewable energy industry, especially for the transportation and wind industries. Suffice it to say that in the new constructions of Boeing 777 at least 30% of composites based on carbon fiber will be used, which allows for reduction of fuel consumption and operational costs.

More than 33,000 professionals, more than 1,200 exhibitors from 112 countries and 120 journalists are expected to attend this event. Among the topics covered there will be "... Fibers (glass, carbon, aramid, flax, hemp, jute, other natural fibers, basalt, boron, ceramic and metal fibers, graphite); Nanoarmature (clay, carbon nanotubes, graphene, others); Fiber sizing and processing; Basic chemicals; Thermosetting resins (polyester, vinylester, acrylic, epoxy resin, polyurethane, bio-based resins, other thermoset resins); Thermoplastic resins (polyethylene, polypropylene, polyamide, PVC, PEEK, PEAK, bio-based resins, other thermoplastic resins); additives and modifiers (gas pedals, modifiers, hardener, fire retardant, hardeners, initiators, other additives); Fillers; gelcoats and coatings; adhesives; core materials (foams, balsa, honeycomb, tubes, other core materials); other matrices (asphalt, carbon, ceramic, concrete, plaster, metal, PVC, rubber, others)".

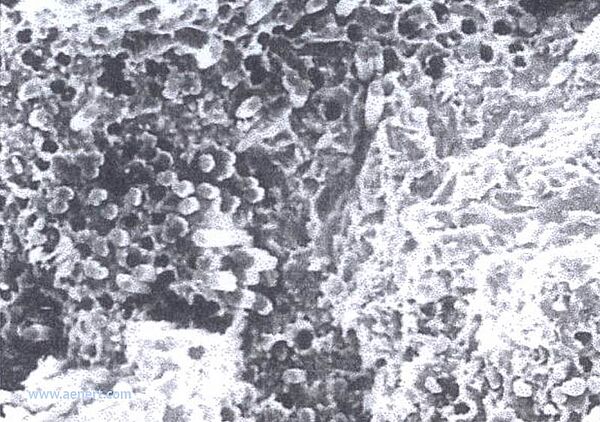

Structure of a composite material with carbon fibers

The exhibits will include: "Equipment to manufacture Raw Materials & Intermediates; Equipment to produce and test Composite parts; Consumables Used With Manufacturing Equipment; Fiber Based Textile Intermediates (All types of fibers); Fiber/Resin Based Semi-Finished Intermediates; Producer Of Other Semi-Finished; Intermediates e.g. Standard Products For Machining" as well as "Software Supplier For Design And/Or Manufacturing; Distributors, Agents & Representatives; Composite Parts Producer By Process; Recycler Of Composite Raw Materials, Intermediates & Finished Parts; Associations, Third Parties, Service Providers & Consultants".

One of the most important technological issues in this industry is the automation of industrial manufacturing of products made of composites, since many operations today are done manually. Among other problematic issues is the creation of composites with carbon fiber on the basis of metal matrix and, first of all, aluminum, which have not yet received decent representation.

By the Editorial Board