Aenert news. Research Laboratory news

In the quest for more efficient and reliable methods to store energy, research on new and improved battery technologies plays an important role. One of the key areas which holds great promise are solid-state batteries. A solid-state battery is a battery technology that uses solid electrodes and a solid electrolyte. However despite their great potential there still have to be overcome many technical problems, including, for example, the formation of filaments, needle-like growths which occur when lithium is used as the anode. Therefore, scientists are constantly searching for new materials to make this battery technology safer. One such material are garnets. They are gemstones which can be used as a potential electrolyte for solid-state batteries and can contribute to improving the exchange of ions from one electrode to the other.

Now (2022), a study carried out at Argonne Laboratory looked at how garnets could improve the efficiency of solid-state batteries. The study used advanced X-ray techniques at Argonne’s Advanced Photon Source and applied two techniques to observe an operating battery with a garnet electrolyte and lithium anode. To do so, they repeatedly charged and discharged the battery until it failed due to filaments and other damage with the aim to track filament growth and material degradation.

The first technique they used was far-field high-energy diffraction microscopy and consisted in directing high-energy synchrotron X-ray beams into a sample while it was rotating. A detector records where the X-ray beams scattered. They employed synchrotron X-rays because they were a billion times brighter and could penetrate much more deeply into materials. This allowed them to better analyse changes occurring deep inside batteries as they operated and characterise smaller features than with normal x-rays. Concerning the garnets, the analysis allowed us to determine the features of individual grains. They found that the garnet grains had different shapes, structures, and orientations and were arranged in different ways. The analysis also showed that small changes occurred while the battery was charged and discharged which made it possible to quantify the mechanical stresses on the grains and the ensuing deformation.

The second characterization technique they employed was characterization technique. High-energy synchrotron X-ray beams were sent into the battery and measured how and where the intensity of the X-ray beams was reduced. With the help of these measurements 3D digital images of the garnet materials’ interior were created. Combining the two techniques allowed the scientists to correlate tiny, grain-level structural features with much bigger damage features, like filaments and fractures.

The team found that it generally was the polymorphic (nonuniform) regions of the garnet materials where much of the filament formation and other large-scale structural damage occurred. The team assumed that polymorphic regions in garnets were a result of the use of dopants during materials processing to optimize performance. This nonuniform distribution of the dopants might then cause the nonuniform structure of garnets.

Scientists have long tried to improve the efficiency of solid-state batteries. In 2016, scientists analysed sulphide solid electrolytes regarding conductivity, electrochemical properties, and appropriate mechanical properties, such as formability, processability, and elastic modulus. The sulphide electrolyte with a Li7P3S11 crystal structure was found to have a high Li+ ion conductivity of 1.7 × 10−2 S cm−1 at 25°C. Sulphide electrolytes were found to show better formability than oxide electrolytes. The team of scientists made A dense electrolyte separator and closely attached interfaces with active material particles via “room-temperature sintering” of sulphides by means of cold pressing without heat treatment. Elastic moduli for sulphide electrolytes were found to be smaller than that of oxide electrolytes, and Na2S–P2S5 glass electrolytes had smaller Young’s modulus (the ratio of tensile stress (σ) to tensile strain (ε)) than Li2S–P2S5 electrolytes. Through cross-sectional SEM observations for a positive electrode layer, it was shown that sulphide electrolyte coating on active material particles made interface areas larger even when the volume of electrolyte was very small. This also enhanced the energy density of bulk-type solid-state batteries. Surface coating of electrode particles and preparation of nanocomposite were shown to increase the reversible capacity of the batteries.

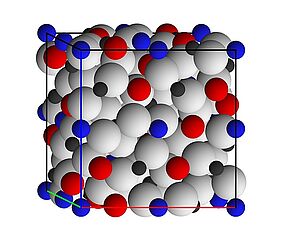

Image: Composition dependence of conductivity at 25°C for (100-x)Na3PS4·xNa4SiS4 (mol%) glass–ceramic electrolytes. The inset shows the electron density distribution of the cubic Na3PS4 structure.

Source: Akitoshi Hayashi, Atsushi Sakuda and Masahiro Tatsumisago/ Development of Sulfide Solid Electrolytes and Interface Formation Processes for Bulk-Type All-Solid-State Li and Na Batteries/ Front. Energy Res., 15 July 2016, Sec. Electrochemical Energy Conversion and Storage, Volume 4 – 2016/ https://doi.org/10.3389/fenrg.2016.00025/ Open Source This is an Open Access article is distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0)

In 2020, a solution-based printing process followed by rapid (~3 s) high-temperature (~1500°C) reactive sintering was designed with the aim of using it for creating high-performance ceramic SSE films. The SSEs showed a dense, uniform structure and a superior ionic conductivity of up to 1 mS/cm. Moreover, the fabrication time from precursor to final product was typically 10 to 100 times faster than conventional SSE syntheses. Also, this printing and rapid sintering process also enabled a layerwise fabrication of multilayer structures without cross-contamination. To proof their concept, the scientists built a printed solid-state battery with conformal interfaces and excellent cycling stability. The technique was found to be suitable for other thin-film SSEs. This opened up previously unexplored opportunities in developing high-performance solid-state batteries and other thin-film devices.

Image: Optimization of ceramic film printing and sintering conditions: (A) SSE precursor ink prepared by dispersing the mixed oxide precursors (Li2CO3, La2O3, ZrO2, and Ta2O5) in ethanol. (B) The SSE ink shows good fluidity. (C) Printing the garnet precursor ink by spray coating through a mask. (D) Printing the SSE precursor ink by the doctor blade method. (E) The printed SSE film is scalable and flexible. (F to H) Schematic and cross-sectional morphology of LLZTO garnet films sintered at different temperatures and times, in which an adequate sintering temperature with appropriate sintering time is necessary to acquire a dense garnet film with limited Li loss and uniform grain size distribution. XRD patterns of LLZTO films sintered at temperatures ranging from (I) 800° to 1300°C and hold times ranging from 1 to 180 s and at (J) 1400° to 1700°C and hold times ranging from 1 to 10 s. a.u., arbitrary units. Photo credit: Weiwei Ping, University of Maryland, College Park.

Source: Weiwei Ping, Chengwei Wang, Ruiliu Wang, Qi Dong, Zhiwei Lin, Alexandra H. Brozena, Jiaqi Dai, Jian Luo, and Liangbing Hu/ Printable, high-performance solid-state electrolyte films/ Science Advances Vol 6, Issue 47, 18 Nov 2020/ DOI: 10.1126/sciadv.abc8641/ Open Source This is an Open Access article is distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0)

There are several advantages involved in using garnets as electrolyte: Garnets are a promising material because they can move ions through batteries quickly and are relatively stable in the presence of lithium. However, filaments can also form with garnets. Therefore, one of the chief aims of this research was to understand the reason for the formation of filaments and find possible ways to engineer garnets to eliminate filaments. In this endeavour, the diffraction technique was of great help as it enabled the team to analyse individual grains in battery materials. After the upgrade of the APS, this kind of research is set to become even more powerful as it will increase the brightness of the facility’s X-ray beams by up to 500 times.

Once the upgrade is accomplished the scientists will be able to analyse individual grains and observe how they change during operation. Once the main culprits have been identified, the path for the development or more stable and efficient solid-state batteries is set.

By the Editorial Board