Aenert news. Invention analysis

Previously, in a number of articles related to the technologies of energy production from biomass we revised patenting trends in biomass gasification (pre-treatment of feedstock on 04.03.2023 and fluidized bed reactors on 31.01.2023), cellulosic ethanol production (19.04.2023), and biofuel production from algae (11.05.2023).

Today we will take a look at another popular technology in this field – production of biogas. For this purpose we have collected more than 10000 inventions published over the past 20 years and analyzed them using the Advanced Energy Technologies methodology. The patents and patent applications under revision were published in 69 patent offices around the world by 3516 applicants from 58 countries.

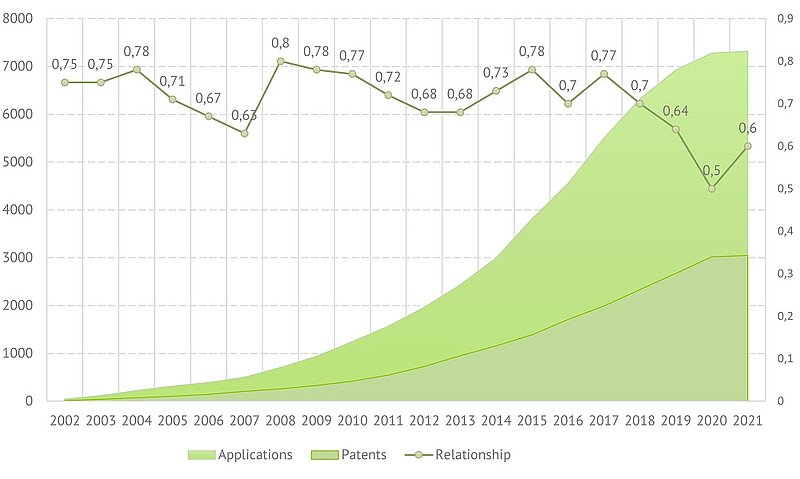

Bioenergy. Biogas. Cumulative number of patents and applications*, relationship of number of applications to total number of documents by year

*Areas representing patents and applications are overlapping

In the collection of documents used for this analysis, the peak values in the number of granted patents were achieved in 2016-2020. In the case of patent applications, the highest number of registered documents was in 2015-2019. In recent years, the number of start documents that didn’t belong to any previously formed patent family was varying in the range of 29%-57%.

The number of newly appearing applicants in the collection of documents related to biogas production was on the rise until 2017-2018 with a slight decline afterwards. Similar picture can be seen in new IPC subgroups appearing in the selection. The appearance of new patent offices was stable until 2015, with a noticeable slowdown afterwards. This may indicate that new companies, organizations and individuals continue to appear, who are willing to participate in the development of biogas production technologies. Also, it can be seen that the subject continues to expand in technical aspect. Although new offices appeared rarely in the past few years in the collection of documents under revision, it should be taken into consideration that the total number of offices where the documents were published, already is impressive.

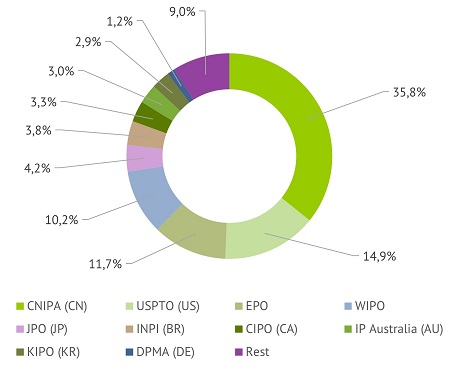

The largest number of patents were granted during the twenty-year period in the CNIPA (CN) patent office – almost 23% of the entire pool of patents. It was followed by USPTO (US) and EPO with around 22% and 14%, respectively. CNIPA (CN) (around 36%), USPTO (US) (around 15%), and EPO (almost 12%) were leading by the number of recent patent applications registered in the 5-year period. JPO (JP), KIPO (KR), DPMA (DE), Rospatent (RU), IP Australia (AU), and CIPO (CA) should also be mentioned as the patent offices that granted more than 100 patents each on the subject of interest in the collection under revision.

Bioenergy. Biogas. Breakdown of inventions by patent offices. Patents, 20 years (left); Applications, 5 years (right)

Germany holds the first position by being the country of residence for the largest number of applicants participating in the patenting process, having almost 19% of all cases in patents granted during the 20-year period. China holds the second place with about 18% of all cases, followed by the United States with almost 16%. In the case of 5-year applications the leaders were China with almost 30% of cases, the United States – around 12%, and Germany - around 10%.

Below is are lists of top 10 applicants having the highest Market involvement ratio for patents published in the 20-year period, and applications published in the past 5 years (Market involvement ratio = volume ratio multiplied by ownership ratio, where Volume ratio - share of applicant documents in total number of documents, Ownership ratio - applicant's participation share in total number of documents):

Bioenergy. Biogas. Top applicants by Market involvement ratio. Patents

| Status | Country | Name | Volume ratio, % | Ownership ratio, % | Market involvement ratio, % |

|---|---|---|---|---|---|

| Company | NL | DSM IP Assets B.V. | 1.7 | 100 | 1.70 |

| Company | AT | Evonik Fibres Gmbh | 1.24 | 96.04 | 1.19 |

| Company | DE | BASF, SE | 1.1 | 79.73 | 0.88 |

| Company | DE | BEKON Energy Technologies GmbH & Co. KG | 0.84 | 96 | 0.81 |

| Company | US | Nalco Company | 0.84 | 87.2 | 0.73 |

| Company | US | UOP LLC | 0.73 | 84.74 | 0.62 |

| Organization | CN | Jiaxing Vocational Technical College | 0.7 | 100 | 0.70 |

| Company | JP | Osaka Gas Corporation | 0.7 | 100 | 0.70 |

| Company | FR | Air Liquide | 0.6 | 90.48 | 0.54 |

| Company | DE | Evonik Degussa GmbH | 0.6 | 97.22 | 0.58 |

In the pool of patents describing the technologies of biogas production, DSM IP Assets B.V. (NL) was in the lead by the number of documents among all applicants – 48 patents. It was followed by Evonik Fibres Gmbh (AT) - 37, and BASF, SE (DE) - 33. In terms of recently published patent applications, the leaders were DSM IP Assets B.V. (NL) - 129, BASF, SE (DE) - 88, Haldor Topsoe A/S (DK) - 44, and Evonik Fibres Gmbh (AT) - 42 documents.

Bioenergy. Biogas. Top applicants by Market involvement ratio. Applications

| Status | Country | Name | Volume ratio, % | Ownership ratio, % | Market involvement ratio, % |

|---|---|---|---|---|---|

| Company | NL | DSM IP Assets B.V. | 4.1 | 91.59 | 3.76 |

| Company | DE | BASF, SE | 3.12 | 97.29 | 3.04 |

| Company | DK | Haldor Topsoe A/S | 1.42 | 100 | 1.42 |

| Company | AT | Evonik Fibres Gmbh | 1.13 | 98.39 | 1.11 |

| Company | JP | Osaka Gas Corporation | 1.05 | 100 | 1.05 |

| Company | CH | Clariant International AG | 0.94 | 100 | 0.94 |

| Organization | US | University of California | 0.94 | 59.62 | 0.56 |

| Company | DE | Fluorchemie GmbH Frankfurt | 0.94 | 100 | 0.94 |

| Company | US | ExxonMobil Research and Engineering Company | 0.91 | 58 | 0.53 |

| Company | US | Mustang Sampling LLC | 0.87 | 100 | 0.87 |

In the pool of patents and patent applications related to biogas production, the most commonly encountered problems were Low efficiency of main processes, High OPEX / Poor performance, and Low efficiency of product treatment. In the majority of cases, technical solutions disclosed in the patent documents under revision were represented in the form of methods. Devices were encountered a little less often in the documents, while the number of compositions was substantially smaller. The most popular IPC subgroups assigned to the patent documents were: C12M1/107 (with means for collecting fermentation gases, e.g. methane), C02F11/04 (Anaerobic treatment; Production of methane by such processes), C12P5/02 (acyclic), C12M1/00 (Apparatus for enzymology or microbiology), and C02F3/28 (Anaerobic digestion processes).

The largest patent family of the entire collection made for the present analysis includes 55 patent documents and is represented by core document US20190032093A1 (Core document is a base document for which a complete description of the invention is available in generally-accessible patent databases):

Process for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars / A: US20190032093A1 / IPC: C12P7/10, C12P5/02, C12P7/16, C12P7/18, C12P7/20, C12P7/40, C12P7/42, C12P7/46, C12P7/48, C12P7/54, C12P7/56, C12P17/10, C12P19/02, C12P19/14, C12P35/00 / Noordam Bertus, Berkhout Michael Petrus Jozef / DSM IP Assets BV / Appl. date: 04.10.2018; Publ. date: 31.01.2019 / United States Patent and Trademark Office / Core document: US20190032093A1 / Technology categories: BG, CE / Technology elements: PTF / Problems: HCG, HOP, LEMP / Technical solution types: M / Claims: 20 / Rating: 15

It is followed by patent families having 43 and 40 patent documents and represented by core documents US20190062794A1 and US8465645B2, respectively:

Process for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars / A: US20190062794A1 / IPC: C12P19/02, C12P19/14, C13K1/02, C13K13/00, D21C3/26 / Noordam Bertus, Berkhout Michael Petrus Jozef / DSM IP Assets BV / Appl. date: 29.10.2018; Publ. date: 28.02.2019 / United States Patent and Trademark Office / Core document: US20190062794A1 / Technology categories: BG, CE / Technology elements: PTF / Problems: HCG, HOP, LEMP / Technical solution types: M / Claims: 15 / Rating: 14

Renewable energy microgeneration system / P: US8465645B2 / IPC: C02F3/28, C05F7/00, C02F11/04 / Sassow Nicolas W / SEaB Energy Holdings Ltd., Sassow Nicolas W / Appl. date: 18.06.2012; Publ. date: 18.06.2013 / United States Patent and Trademark Office / Core document: US8465645B2 / Technology categories: BG / Technology elements: CD, PP, PTF / Problems: AOP, HOP, LEMP / Technical solution types: D, M / Claims: 24 / Rating: 17

The following abbreviations are used in the documents hereinbefore and hereinafter: C - Composition; D - Device; M - Method; AL - Algae; BG - Biogas; CE - Cellulosic ethanol; LFG - Landfill gas; MW - Methane from wastewater; PT - Pyrolysis & torrefaction; CD - Methods of control and diagnostics; COS - Chemistry and other substances; CS - Capture and separation; CUW - Capture, utilization of solid, liquid and gaseous wastes; FT - Finishing treatment; PP - Primary processing; PTF - Pre-treatment of feedstock; AOP - Administrative and organisational problems; ESI - Environmental and social impact; HCD - High CAPEX / Development; HCG - High costs in general; HOP - High OPEX / Poor performance; HOU - High OPEX / Utilization; LEMP - Low efficiency of main processes; LEPT - Low efficiency of product treatment.

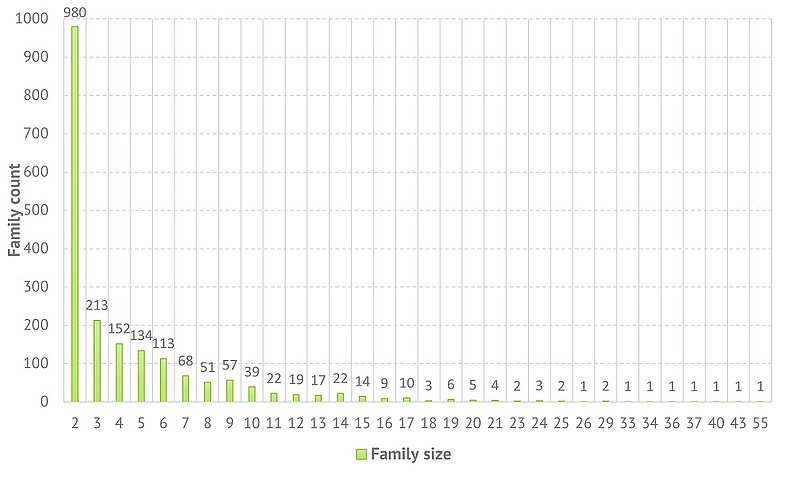

Bioenergy. Biogas. Breakdown of documents by family size. Patents and applications

Some examples of inventions related to biogas production and having the highest rating calculated using Advanced Energy Technologies methodology are provided below:

Bioenergy. Biogas. Prominent patent documents by rating:

Process for separation of gases / P: US8999038B2 / IPC: B01D53/22, C10L3/10 / Ungerank Markus, Baumgarten Goetz, Priske Markus, Roegl Harald / Evonik Fibres GmbH, Ungerank Markus, Baumgarten Goetz, Priske Markus, Roegl Harald / Appl. date: 26.05.2011; Publ. date: 07.04.2015 / United States Patent and Trademark Office / Core document: US8999038B2 / Technology categories: BG, LFG, MW / Technology elements: FT / Problems: ESI, HCD, HOP, LEPT / Technical solution types: C, D, M / Claims: 58 / Rating: 22

Process for separation of gases / P: AU2011273795B2 / IPC: B01D53/22, C10L3/10 / Ungerank Markus, Baumgarten Goetz, Priske Markus, Roegl Harald / Evonik Fibres GmbH / Appl. date: 26.05.2011; Publ. date: 06.02.2014 / IP Australia / Core document: US8999038B2 / Technology categories: BG, LFG, MW / Technology elements: FT / Problems: ESI, HCD, HOP, LEPT / Technical solution types: C, D, M / Claims: 26 / Rating: 22

从藻生物质提取脂质的方法 (en: Process for the extraction of lipids from algal biomass) / P: CN102365355B / IPC: C11B1/10, C11C3/00, C11C3/12, C12P7/64 / D'Addario Ezio Nicola, D'Angeli Edoardo, Medici Roberto / ENI SpA / Appl. date: 28.01.2010; Publ. date: 06.11.2013 / National Intellectual Property Administration / Core document: US20120016145A1 / Technology categories: AL, BG, PT / Technology elements: COS, CUW, PP, PTF / Problems: HCG, LEMP / Technical solution types: C, M / Claims: 22 / Rating: 22

Heat-stable carbonic anhydrases and their use / P: US7892814B2 / IPC: C02F3/34, C12M1/00 / Borchert Martin, Saunders Paria / Novozymes AS / Appl. date: 03.08.2010; Publ. date: 22.02.2011 / United States Patent and Trademark Office / Core document: US8697428B2 / Technology categories: BG / Technology elements: FT / Problems: ESI, HOU, LEPT / Technical solution types: C, M / Claims: 32 / Rating: 21

Heat-stable carbonic anhydrases and their use / P: US9382527B2 / IPC: B01D53/62, B01D53/84, C12N9/88, C12P7/40 / Borchert Martin / Novozymes AS, Novozymes North America Inc / Appl. date: 17.12.2014; Publ. date: 05.07.2016 / United States Patent and Trademark Office / Core document: US9382527B2 / Technology categories: BG / Technology elements: FT / Problems: ESI, HOU, LEPT / Technical solution types: C, M / Claims: 24 / Rating: 21

Process for separation of gases / P: CA2804233C / IPC: B01D53/22, C10L3/10 / Ungerank Markus, Baumgarten Goetz, Priske Markus, Roegl Harald / Evonik Fibres GmbH / Appl. date: 26.05.2011; Publ. date: 10.10.2017 / Canadian Intellectual Property Office / Core document: US8999038B2 / Technology categories: BG, LFG, MW / Technology elements: FT / Problems: ESI, HCD, HOP, LEPT / Technical solution types: C, D, M / Claims: 38 / Rating: 21

Process for the extraction of fatty acids from algal biomass / P: US8535397B2 / IPC: C10L1/18 / D'Addario Ezio Nicola, Capuano Federico, D'Angeli Edoardo, Medici Roberto / ENI SpA, D'Addario Ezio Nicola, Capuano Federico, D'Angeli Edoardo, Medici Roberto / Appl. date: 19.06.2009; Publ. date: 17.09.2013 / United States Patent and Trademark Office / Core document: US8535397B2 / Technology categories: AL, BG / Technology elements: COS, CS, CUW, PP, PTF / Problems: HOP, LEMP / Technical solution types: C, M / Claims: 32 / Rating: 21

In the recent patents and patent applications related to biogas production, the most noticeable groups of inventions were those aimed at solving the problems of Low efficiency of main processes, High OPEX / Poor performance, and Low efficiency of product treatment. Below we provide several examples of patent documents that concern these groups of technical solutions:

- US10384969B2 - increased throughput of a biogas production and utilization system is achieved by a method comprising macerating waste, wetting it with liquid comprising bacteria, heating it and keeping at a first temperature, performing anaerobic digestion with the bacteria at a second temperature in a tank immune to anammox bacteria and methagenic bacteria, and removing a portion of liquid from the digestion process to wet other wastes;

- US10457962B2 - a mobile biogas production system housed in a container comprising a digester with a hydrolysis tank, a solids separator, a methanogenesis tank with fixed film methanogens, a heater to heat the liquid in the system, and a remote data transmission system. The solids separator separates the hydrolysis effluent and transfers the screened hydrolysis effluent to the methanogenesis tank. Biomass conversion in the system is claimed to be quicker and more efficient;

- US11434508B2 - a process for producing sugar from lignocellulosic material involves enzymatic hydrolysis using an enzyme composition preferably derived from Rasamsonia emersonii with GH61 as a key component. The hydrolysis is performed in two phases with different oxygen content, hydrolysis time, and at specific conditions, aiming to improve yields and reduce costs;

- US20200277210A1 - lowered economic cost and improved productivity are achieved by a process for cleaning of a gas-liquid separator, comprising creating a scouring effect through turbulent fluid flows in an anaerobic bioreactor. The scouring effect is achieved by closing a gas pipe that is connected to a gas collector and an open-ended chamber, or opening a gas pipe, thus releasing gas into the headspace of the reactor vessel;

- US10780391B2 - efficiency of contaminant removal from biogas is improved by a method comprising blending the biogas with hydrogen, catalytically combusting the blended gas, hydrogenating sulfur species to hydrogen sulfide, and removing hydrogen sulfide by an adsorption bed. The method can further include steps involving a sulfur polisher, a chlorine removal adsorbent bed, a siloxane removal adsorption bed, and a biogas precooler.

Low efficiency of main processes

Patent US10384969B2 published by Seab Energy Holdings Ltd. (GB) discloses a microgeneration system performing an anaerobic digestion process to generate electricity, biogas and fertilizers. The system comprises holding tanks with an inner wall made of material immune to anammox bacteria and methagenic bacteria, and configured to stir the waste and to perform multi-phase anaerobic digestion. The system further comprises a controller with a processer and a wireless interface to automatically perform the digestion process. The system also comprises a de-watering unit to generate solid fertilizer by drying the material remained after the digestion process, an odor management system comprising filter elements to remove odors from the gas, a gas scrubber to treat the produced gas and produce a fuel-grade gas, and a gas storage system, or a generator to produce electricity by burning the treated gas. According to the method of the invention, the waste is wetted with liquid comprising bacteria, heated and kept at a first temperature, then anaerobic digestion is performed with the bacteria at a second temperature, and a portion of liquid is removed from the digestion process. This portion of liquid is used to wet other waste to repeat the process. The process can also comprise a step of macerating the waste into small pieces before moving the waste to the holding tanks.

The authors of the invention point out the need in a renewable energy generation system having an increased throughput.

The patent belongs to a family comprising 40 patent documents published between 2011 and 2021 in US, CA, WO, GB, EP, AU, AP, MX, CO, EA, CN, JP, HK, NZ, CL, ZA, BR, and MY.

Image from: US10384969B2

100 - apparatus for renewable energy microgeneration; 102 - first container; 104 - second container; 106 - chopper unit; 108 - buffer tank; 110 - small holding tanks; 112 - large holding tank; 114 - de-watering unit; 116 - gas scrubber; 120 - gas storage tank; 122 - biogas engine; 124 - flare; 126 - liquor tank; 130 - compressor enclosure; 136B,136C – piping; 138 - wiring connections; 140 - facia; 142 - loading platform; 144 - door; 146 - external double doors; 148 - control box; 150 - ramp; 152 - louvers; 166 - breaker box; 174 - exhaust stack.

Patent US10457962B2 by Novus Energy LLC (US) and Viresco AD LLC (US) describes a mobile system designed to digest organic matter and produce biogas. The system is housed in a shipping container or trailer that can be transported on trucks or trains. It includes a digester with a hydrolysis tank containing hydrolytic microorganisms, a solids separator to separate undigested solids, and a methanogenesis tank with fixed film methanogens. A heater is provided to heat the liquid in the system. Multiple instruments with detectors are in contact with the liquid or gas in the tanks and are connected to a computer for data collection. The computer is linked to a modem for remote data transmission. The solids separator separates the hydrolysis effluent and transfers the screened hydrolysis effluent to the methanogenesis tank. Additionally, there is an option for a remote computer to control and monitor the digester from a different location.

The authors claim that they have developed improved fermentation methods to convert biomass to biogas quickly and more completely, compared to other solutions.

The patent is a part of a family comprising 10 documents, published in the USPTO patent office in 2014-2019.

Image from: US10457962B2

1 - organic substrate; 2 - grinder; 11 - hydrolysis tank; 12 - hydrolysis effluent; 13 - screened hydrolysis effluent; 14 - solids fraction; 17 - solids separator; 21 - methanogenesis tank; 22 - second methanogenesis tank; 25 - headspace; 41 - substrate; 51 - fixed film; 52 - granular bed methanogens.

High OPEX / Poor performance

Patent US11434508B2 granted to DSM IP Assets B.V. (NL) on 06.09.2022 describes a process for producing sugar and fermentation products from lignocellulosic material for further conversion into useful products, such as biogas. The process involves enzymatic hydrolysis using a specific enzyme composition that includes at least two cellulases, with GH61 as a key component. The enzymatic hydrolysis is carried out in two parts: a first part with minimal or no oxygen and a subsequent second part with increased oxygen levels. The second part constitutes 2% to 80% of the total hydrolysis time. The process can be performed in a reactor with a volume of 1 m3 or more and at a temperature of 45°C or higher. The enzyme composition, which can be derived from a fungus (for example, Rasamsonia emersonii), retains activity for at least 30 hours. The dry matter content during hydrolysis is at least 10 wt % (preferably, 14-33 wt %), and the entire process can be conducted for 5 to 150 hours in batch, fed batch, or continuous culture reactors. Various specific oxygen conditions, dissolved oxygen concentrations, and other parameters are also described in the claims.

With regard to the prior-art solutions, the authors mention high costs of enzyme production and state that the invention optimizes the process by increasing yields and reducing costs.

The patent is a part of a family comprising 63 patent documents published between 2014 and 2023 in CA, WO, AU, CN, KR, MX, EA, EP, BR, IN, US, JP, UA, and MY.

Image from: US11434508B2

Patent application US20200277210A1 filed by Veolia Water Solutions & Technologies Support (FR) discloses a process for the in-situ cleaning of a gas-liquid separator in an anaerobic bioreactor. The cleaning process involves creating a scouring effect through turbulent fluid flows by directing a gas flow within the bioreactor. The gas-liquid separator can include a gas collector that is connected to a closable gas pipe, which in turn is connected to an open-ended chamber of the reactor vessel. Closing the gas pipe allows gas to be released from underneath the gas collector, creating the scouring effect and facilitating the cleaning process. Further, the gas-liquid separator may have a gas channel equipped with a closable gas pipe, which, when opened, releases gas into the headspace of the reactor vessel, inducing the scouring effect and cleaning the gas channel and pipe. The process can be applied to treat fluid aqueous waste streams containing biodegradable organic substances in the anaerobic bioreactor. Additional features of the invention include the use of branched gas pipes, and the arrangement of multiple gas-liquid separators at different levels in the reactor vessel. Intermittent closing and re-opening of the gas pipe provides a preventative cleaning to avoid excessive buildup of solids. The claims of the document also disclose a bioreactor containing such cleaning system and its specific elements.

The authors of the invention mention that the prior-art solutions require additional equipment for fluid cleaning, thus increasing the economic cost of the process and lowering its productivity.

The invention belongs to a family comprising 8 patent documents published in WO, KR, CN, EP, JP, RU, and US in 2017-2020.

Image from: US20200277210A1

1 - bioreactor; 2 - reactor vessel; 3 - effluent discharge pipe; 4 - gas discharge pipe; 5 - gas-liquid separator; 6 - gas collectors; 7a,7b - branched gas pipe; 8 - headspace; 9 - open-ended chamber; 10 - baffle (plate) arrangement.

Low efficiency of product treatment

Patent US10780391B2 by Prasad Alakh (CA) and Marchand Kevin (CA) describes a biogas cleaning method that purifies a biogas waste stream to produce a clean and combustible biogas fuel. The method utilizes a gas control system comprising a hydrogen flow controller and a hydrogen port that blends hydrogen gas into the biogas waste stream in a concentration greater than 2%; a deoxidizer catalyst bed that catalytically combusts the blended hydrogen gas with oxygen in the waste stream to remove oxygen and heat the biogas stream to 250° C. - 400° C; a hydrodesulfurization catalyst bed that receives the heated biogas and hydrogenates sulfur species to hydrogen sulfide; and a hydrogen sulfide removal adsorption bed to remove sulfur from the biogas stream. Additional features include a sulfur polisher adsorption bed comprising copper or nickel in a reduced or oxide state to remove trace sulfur levels, a chlorine removal adsorbent bed, a siloxane removal adsorption bed, and a biogas precooler. The system may also include multiple sulfur adsorbent beds arranged in a lead and lag configuration. The claims of the invention specify acceptable biogas composition and condition, preferred embodiments of individual elements and materials used therein.

The authors point out the need for efficient systems and methods for contaminant removal from biogas.

The patent belongs to a family comprising 17 patent documents published in 2012-2020 in the CA, WO, CN, EP, EA, US, KR, ZA, JP, MX, and BR patent offices.

Image from: US10780391B2

1 - biogas waste stream; 2 - single phase biogas stream; 3,4,5 - gas streams; 6 - liquid stream; 8,9,11,13,14,15,16,17,18 - biogas streams; 10 - hydrogen stream; 19 - fluid line; 20 - bypass fluid line; 21,22 - biogas fuel product streams; 25 - hydrogen stream; 100 - separator; 101 - float valve; 110 - economizer heat exchanger; 120 - refrigeration heat exchanger; 121 - refrigeration system; 130 - separator/filter; 131 - drain trap; 132 - solenoid; 200 - siloxane polisher adsorbent bed; 205 - control valve; 210 - heat exchanger; 230 - de-oxidizer catalyst bed; 240 - hydrodesulfurization catalyst bed; 250 - hydrogen chloride removal adsorption bed; 260 - supplementary heater; 270 - sulfur removal bed; 290 - sulfur polisher bed; 295 - bypass valve.

In the analysis of inventions from the present collection of documents, it was uncovered that, in the majority of cases, inventions related to biogas production describe the primary processes of biogas production, mainly, anaerobic digestion and main related equipment. It is followed by inventions proposing novel technical solutions in finishing treatment – removal of contaminants, such as hydrogen sulfide, moisture, and siloxanes; and by pre-treatment of feedstock, such as sorting, grinding, and crushing.

More detailed information about inventions in the field of biogas production, and patent research methodology can be found on aenert.com, and in BIOGAS. Feedstock, Production, Treatment. Patent Database. July 2021.

By the Editorial Board.