Prospects for the utilization of natural methane hydrate resources in the energy sector

Table of contents

Basic definitions

Gas hydrates are solid crystalline substances in which water molecules, hospitably take on certain conditions, receive the molecules of many other liquids or gases, forming special crystalline compounds of various shapes, called Clathrate [1-3]. During this process gas and water molecules do not enter into chemical bonds, but coexist in the same crystal lattice and ice-like crystalline minerals.

Currently, researchers are particularly interested in natural methane hydrate as a potentially new source of fossil fuel, partly as a result of climate warming caused by an increase in the atmosphere of greenhouse gases, one of which may be methane from hydrates, or due to the huge reserves of methane hydrates. In addition, methane hydrates of non-natural origin can be formed in some technological industries, for example, when transporting gas through pipelines or in chemical reactors and are undesirable travel companions for various production processes. Methane hydrates have a compact structure, and one cubic meter of this substance contains approximately 160 cubic meters of natural gas [2].

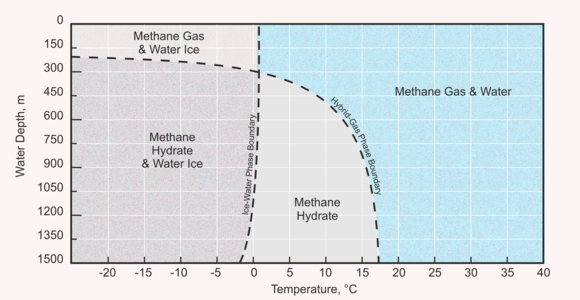

Methane hydrates form stable compounds with simultaneous combination in a specific range of two main external indicators – temperature and pressure, range of low-temperature and moderate-pressure conditions, for example, in sediments from the bottom of the ocean at water depths greater than 300-500 meters [2-4]. Outside this range, methane and water exist separately. This range has moving boundaries – with an increase in pressure, hydrates can form at higher temperatures, and vice versa, with a decrease in temperature, hydrates can exist at a reduced pressure. The plot of the phase diagram of methane hydrates in the coordinates of temperature and pressure (or – the depth of the sea, since a layer of water of a certain volume and density exerts pressure on objects located under water) is shown in Fig. 1. In nature, methane hydrates are found primarily on the bottom of marine continental shelves, as well as in near-surface land in permafrost areas.

Fig. 1. Methane hydrate phase diagram (depth and temperature ranges)

The fractional distribution of methane hydrates in various natural deposits is usually demonstrated by a Gas hydrate resource pyramid. The greatest amount of gas hydrates is in fine-grained marine sediments at the bottom of the continental shelves, therefore these areas form the basis of the pyramid, and the smallest – in the arctic sands in permafrost areas, which are conditionally located on the top of the pyramid, thereby demonstrating that their volume is minimal [1, 2, 5, 6].

Methane Hydrate Resources

Estimates of methane hydrate resources are of great interest, given the potential impact of methane on the climate or future energy supply; however, the scale of the task and the associated objective lack of a comprehensive and universally recognized methodology significantly limit the capabilities of researchers. Therefore, in the technical literature there are a large number of resource estimates, characterized by a large spread of data and a wide spread between limit values. For example, in [1,7], with references to earlier sources, the global methane content in hydrates is ranging from 1,000 to 10,000 gigatonnes of carbon (GtC). This is more than all other fossil sources combined. These figures are mentioned in [8] – 20,000 trillion cubic meters, or about 700,000 Tcf and 21,444 Tcf for hydrate deposits in the Gulf of Mexico. The same data for global coverage are given in [9], median estimates place Japan's reserves at 6 trillion cubic meters, China's at 5 trillion cubic meters and India's at 26 trillion cubic meters. In [2] with reference to [10], the following estimates of gas hydrate resources in the world are given: 1,800-12,400 gigatons of carbon (GtC), corresponding to 3-24.8×1015 cubic meters (106,000-876,000 Tcf). Among the resource estimates of individual countries and regions, works are often cited [11-13], and for resources in the allocated natural sediments [5]. In [11,12], the average values of world resources of methane hydrates in place were slightly higher than 43,000 Tcm, while the most prosperous methane hydrates resources, according to the author, are in the USA, the Arctic Ocean, Latin America and the Caribbean, as well as the countries of the former Soviet Union. In [13], in-place gas hydrate resource volumes of Atlantic OCS, Pacific OCS, and Gulf of Mexico OCS estimates are 2,056; 2,209 and 11,112 Tcf respectively for 95% probability. According to the author [5], more than 95% in-place hydrates are concentrated in deep marine zones. For comparison, onshore permafrost contains just over 1% of gas hydrate resources.

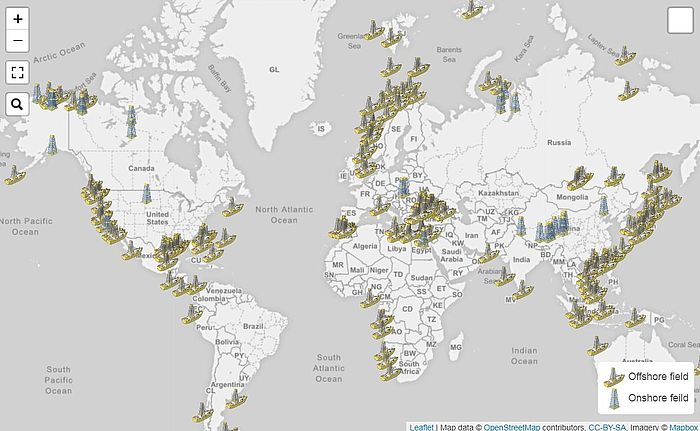

In [1, 2, 5, 6, 12] you can see the distribution of the gas hydrate stability zone in the world, as well as get acquainted with quite detailed maps of the locations of their clusters. Below, Fig. 2 offers an interactive map of methane hydrate accumulations, based on the selection and analysis of thematic research publications of leading researchers devoted to the study of these specific clusters and containing as an application a list of selected publications (mainly over the past 15 years) for each object. Most of the clusters shown on the map are located in marine areas, and onshore clusters are concentrated mainly in the northern regions of Canada and the USA, Russia and the Tibetan part of China.

Fig. 2. Map of accumulations of gas hydrates, data on which are presented in the technical literature and for which studies have been conducted

In total, the map contains more than 350 studied to different degrees accumulation points of methane hydrates in the offshore zone and more than 40 in the mainland. Of these, 15 deposits are represented in the USA (there is an extensive library for the Alaska North Slope and Gulf Of Mexico regions), 30 in China (Qinghai-Tibet Plateau and Shenhu in the South China Sea are the most studied), 49 in Russia ( the most representative in terms of the number of publications are the Baikal zone, Messoyakha – West Siberian Basin, Arctic Shelf and the Sakhalin Shelf), in Canada – 20 (the areas of Mallik – Mackenzie Delta and Cascadia Margin are especially representative), in Japan – 19 (primarily Nankai Trough, as well as Okinawa Trough and Joetsu Basin). Among other locations popular with researchers, it is necessary to highlight – Ulleung Basin (South Korea), Krishna-Godavari (India) and the Hikurangi Margin (New Zealand). The data is constantly updated and may be useful to researchers and engineers involved in the study of methane hydrates and various technological applications associated with them.

Mainstream technologies

Currently, there is no industrial production of methane from hydrates anywhere in the world, nevertheless, a significant amount of accumulated experimental data on gas exploration, activation, drilling and extraction, detailed engineering solutions and theoretical models created allow us to form real ideas about future industrial technologies. A detailed list of numerous publications on the results of these studies can be found on websites of the U.S. Geological Survey (U.S. Geological Survey Gas Hydrates Project) and the National Energy Technology Laboratory, as well as, for example, in [15,16].

The technological processes necessary for the extraction of methane from hydrates are in many ways similar to the traditional ones used in modern natural gas production. This primarily includes exploration of hydrate accumulations, a detailed study of the characteristics of the discovered occurrences, which under certain conditions, by analogy with traditional terminology, can be called a field, the development of this field, the selection of the optimal production method, and the storage and transportation of the resulting product. However, the numerous features of gas hydrate deposits require the development and application of special measures. Firstly, methane in the composition of hydrates is in a bound state and for its extraction it is first necessary to activate it, i.e. transfer to a new energy state where methane can be released from the crystal lattice of hardened water. Secondly, this operation should take place in a controlled and safe mode, since the simultaneous release of a significant amount of gas can lead to emergency situations, as well as environmental disruptions. Thirdly, the exploration of hydrated accumulations by traditional methods requires taking into account many additional factors and, in essence, developing special applications. Fourthly, accumulations of gas hydrates are concentrated either in the Arctic latitudes on the mainland or in offshore zones, which imposes additional serious limitations of both a technical and infrastructural nature on the processes of exploration and, moreover, production and subsequent transportation of this resource. Finally, all these processes are very costly, but if they are carried out for the extraction of natural gas or oil there is an adequate understanding based on existing experience of the correlation of the financial performance of the processes, and the level of risks that can be used to make reasonable estimates of the prospects of the event, then such a clear picture is not available regarding the production of gas hydrates; moreover, it is clear that the level of risks in this case for a long time will significantly exceed the level of possible financial return.

To assess hydrates occurrences various forms of Geophysical Exploration are used most often, for example, they are seismic, including deep seismic sounding, acoustic sensing, Electromagnetic Surveying and others. The essence of most methods is based on the generation of primary wave oscillations of a specific type by special devices, which propagate in natural layers and are reflected from boundaries with different physical properties to form new waves with individual characteristics. As a result of their fixation and decryption of the obtained data, stability zones of gas hydrates are determined, which for the case of their placement on the seabed are called BSR (Bottom Simulating Reflector). High-quality results can be obtained using 3D seismic data, which can extract information on subsurface boundaries and even on gas concentration in rocks. A review of remote sensing data with an emphasis on low frequency exploration 3D seismic is given, for example, in [17]. There are serious prospects for electromagnetic exploration, since gas hydrates significantly differ in their electrophysical properties from the surrounding rock in bottom sediments or in permafrost.

Another invariable method for analyzing hydrate accumulations is Geochemical Exploration [18], through which it is possible to determine the concentration of methane in hydrates, its distribution, the chemical composition of water and much more. Geochemical exploration is carried out using actual core samples in combination with logging-while-drilling (LWD) data. As the analysis shows in [19], exploratory drilling in gas hydrate reservoirs is in many ways similar to conventional drilling. Based on the results of these studies, the main characteristics of Gas hydrate reservoirs are determined. Four main hydrate-bearing layers are distinguished [20]. The first three of them contain overburden and underburden substances, the fourth class consists only of a hydrate-containing layer. In the first class reservoirs there is the free gas zone under the hydrate layer and in the second – the water zone. In addition, an extended classification system is considered, taking into account the varied nature of these deposits. Deposits in their structure can be assigned to one of the types of classifier from [20], including unconsolidated thinly-interbedded sands and shales massively bedded layers of accumulations within unconsolidated, fine-grained, low-permeability sediments, such as pore-filling mode or grain-displacing veins, as well as bottom sediments of the “mounds” type, and accumulations within rocks.

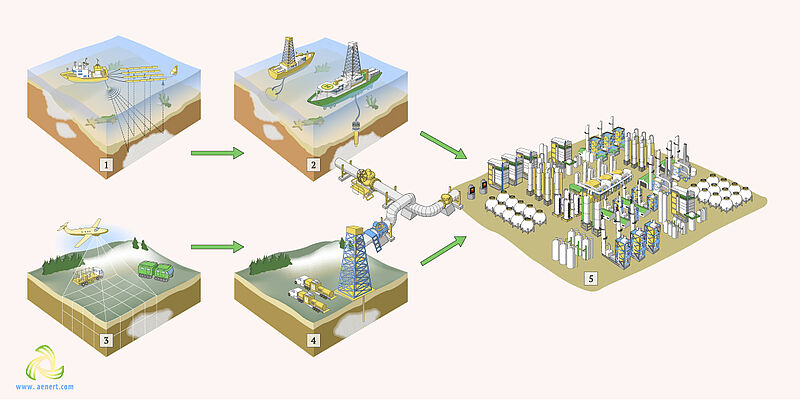

Based on the data obtained during the exploration, it is possible to prepare the optimal technology for methane activation in hydrates, i.e. its release from the hydrate structure. Obviously, the basis for this is the state diagram of the hydrate and, above all, the boundary conditions for its decomposition into constituent water and gas molecules. Based on this, the main methods for dissociation of methane hydrates – Chemical activation, Thermal activation, Depressurization, Injection and displacement [6,15,18] were prepared and tested during the implementation of experimental programs. In addition, in scientific articles and patents there are descriptions of other options, for example, biological activation, electromagnetic or microwave heating, solid fluidization. Nevertheless, the first four options, which have already become "classic," remain the most studied and close to industrial use. The general simplified scheme of the main processes of activation of methane hydrates is shown in Fig. 3.

Fig. 3. A simplified scheme for the activation and production of methane hydrates

A. CO2 injection to gas hydrates field

A1. Drilling

A2. Cementation of wells

A3. Down pipe for injecting carbom dioxid

A4. Carbon dioxid injection

A5. Extrication methane

A6. Storage of methane

B. Temperature rise of gas hydrates field

C. Pressure reduction of gas hydrates field

D. Chemical injection to gas hydrates field

The fundamental possibility of the release of methane from its hydrates by injection of carbon dioxide is based on the fact that the thermodynamically hydrated carbon dioxide is more stable than methane hydrate, since its formation enthalpy (-57.98 kJ / mol) is less than that of the latter (-54.49 kJ / mol) [18]. As a result of the diffusion of СО2 molecules into the porous structure of methane hydrate, methane molecules and carbon dioxide are rearranged and methane molecules are released to the surface. This method is primarily suitable for reservoirs with low water saturation [18]. The technology is characterized by high energy consumption, low gas production rate and environmental issues [18]. The method was successfully tested by ConocoPhillips in Alaska (Ignik Sikumi area) in 2012, when 24,000 m3 of methane was produced within 30 days [7,15,20]. The attractiveness of this technology is connected, among other things, with the prospects of partial “burial” of carbon dioxide as the main reason for the greenhouse effect, although it is obvious that the risks of leakage of a more dangerous gas – methane are disproportionately higher.

Thermal activation is carried out by supplying external heat through the wellbore or through special point sources to increase the temperature in the reservoir above the dissociation temperature of methane hydrate. The method is characterized by high energy consumption, since a large amount of energy is dissipated into the external environment, but is well suited for the first class reservoirs [18]. The method was tested for several days in 2002 in the Mackenzie Delta, Canada. The project involved the Consortium of Geological Survey of Canada, JOGMEC, U.S. DOE, U.S. Geological Survey, India Ministry of Petroleum and Natural Gas, etc. [7,15,20]. Later, this technology was used in combination with other activation methods, and primarily with the depressurization method, which is currently considered the most productive and cost effective. According to [18], depressurization is most suitable for collectors of the first type. This method has a representative and successful history. In 2007 and 2008, it was tested in the Mackenzie Delta, Canada, in 2013 and 2017 in Nankai trough, Japan, and also in 2017 in Shenhu area of SCS, China [7,15,20-24]. The most successful trials were in 2017 in Nankai trough, Japan and Shenhu area of SCS, China, when 200,000 m3 (24 days of operation) and 309,000 m3 (60 days of operation), respectively, were produced, which allowed many members of the press to announce the coming energy revolution [21]. Of course, this was an important success, but it is too early to talk about the industrial production of methane from gas hydrates. Clearly, it will take a lot of time for a detailed study of all stages of production, including exploration, activation, extraction, storage and transportation of methane. You can find many scientific publications and patent applications on the development of methane hydrate production technologies in the library of the Advanced Energy Technologies website. Below, as an example, there are links to scientific articles fixing new technological research:

– [25] considers methods for the optimal design of methane production from hydrates through solid fluidization;

– [26] examines the conditions for dissociation of hydrates depending on the Different Horizontal Well Configuration;

– [27] evaluates hydrate dissociation conditions by Warm Brine Stimulation Combined Depressurization;

– in [28], the results of an experimental study of the use of Polyethylene Glycol Drilling Fluid for Drilling;

– in [29-36], various applications of carbon dioxide as a methane substituent in hydrates were studied, including in combination with other gases and activation methods.

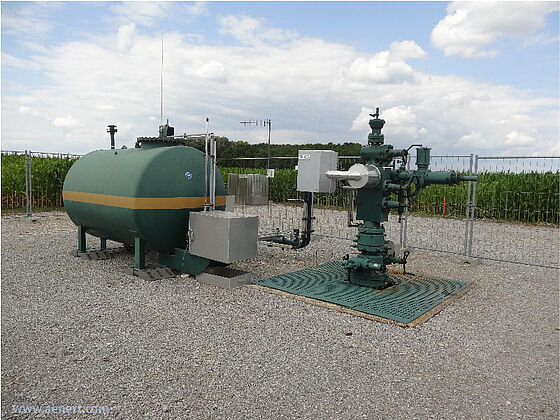

Based on the usual stages of the production of traditional gas, as well as on the material obtained from numerous experimental and theoretical studies of hydrates, in the most general terms, the technological process for the production of methane from gas hydrates can be represented in the following form – Fig. 4.

Fig. 4. Stages of exploration, production and processing of methane from hydrates

To implement plans for the industrial production of methane hydrates, it is necessary to solve several critical problems that can be combined into three large groups – technological problems, environmental problems and financial barriers. In addition to the aforementioned problems associated with the exploration of accumulations of methane hydrates and the identification of the main characteristics of reservoirs, the range of technological problems significantly expands when considering drilling, gas storage and transportation. Since the main resources of methane hydrates are concentrated in offshore zones, this determines the use of the most technically complex offshore processes. Despite the fact that there is rich and successful experience in the extraction of natural gas in offshore zones, methane production from hydrates requires taking into account a significantly larger number of factors determining the stability and safety of production processes. For example, serious problems can arise during Gas Leakages and Gas Releases due to the peculiarities of gas hydrate reservoirs [6], and activation processes should be carried out according to strictly-regulated rules, ensuring a controlled level of methane dissociation. However, given that hydrate accumulations are not a homogeneous mass that uniquely corresponds to any mathematical model, but a complex natural substance that accumulates various forms of its own internal organization, the risks of disruption of established and well-thought-out technological regulations will always remain, although they may be minimized. Another problem associated with the extraction of methane hydrates is associated with traditional gas storage and transportation processes. To solve these issues, expensive infrastructure is required, which on the other hand means that gas hydrate accumulations, where production is supposed to be, must correspond to the scale of conventional gas fields, which in itself is not always feasible.

The issues that environmentalists are most focused on are associated with the Geohazards entailing instability and methane emission. Obviously, the solution to this issue can only be found within the existing technological capabilities on the basis of a unique understanding of the nature of these processes. However, as emphasized in [6], the accumulated research material is not yet sufficient to create a complete model of the behaviour of gas hydrates under various conditions, and additional studies are required.

The financial problems of methane extraction from hydrates are also a serious deterrent to the development of this area. Accumulations of methane hydrates are located either in offshore zones or in the Arctic regions, which requires large expenditures for research and development of technologies. In addition, each element of the methane production chain from hydrates requires the development of new, expensive applications in relation to existing technologies. The estimated production cost of natural gas from hydrates is between $4.4 and $8.6/GJ. In comparison, the production costs of new conventional natural gas resources range from $0.5/GJ to $5.7/GJ, with some exceptions [37]. It was also mentioned above that the risks of developing hydrate deposits are not yet comparable with the risks of developing traditional natural gas deposits.

Research and innovations

Studies of various aspects of the existence of natural gas hydrates, as well as numerous technological applications, today attract the attention of a large number of scientists and engineers from different countries, which found expression in registered patent solutions and especially in the presence of a significant number of scientific publications. Below are brief results of the analysis of research and innovation in this area over the past ten years.

About 1,500 patent applications filed with 31 patent offices in the world between 2009 and 2018 were selected for consideration, which can clearly be attributed to the technological aspects of the exploration and production of natural methane hydrates. The search was carried out in the patent databases of Google and LENS. Patent documents related to the problems of hydrate formation in technological processes, methods or equipment for studying the properties of hydrates in laboratory conditions, technical solutions related, for example, to methods of studying natural hydrates, regardless of the applied issues of methane extraction or cluster exploration for mining purposes, were not taken into account. A total of 499 applicants from 23 countries participated in the creation of patent applications. The analysis technique can be found on the Advanced Energy Technologies website in the Research and Analysis section.

For the analysis of scientific publications from the Google Scholar database during an end-to-end search using the simplest keywords, about 2,500 scientific publications were found published by representatives of 62 countries in various publications and presented as short abstracts in this database of scientific publications.

The publications mainly concerned the technological issues of exploration and production of methane hydrates, although in this case, unlike patent applications, an unambiguous interpretation was not always possible, especially in the absence of free access to the full text of the publications. Links to all selected articles can be found in the library on the Advanced Energy Technologies website.

The distribution of patent applications among the patent offices of the world is shown in Fig. 5, and research publications among the leading online publications in Fig. 6. The category under the common name Google includes articles published outside the online publications listed below, including those published in an independent version. The most representative offices for the period under review were the CNIPA Chinese Patent Office and the Elsevier Corporation Science Direct online system of scientific publications, where a little over 30% of patent applications and more than 20% of scientific publications were concentrated, respectively.

Fig. 5 and 6. Distribution of patent applications among patent offices of the world (left) and scientific publications among leading online systems (right)

Source: Advanced Energy Technologies

Over 15% of patent applications were filed at the US Patent Office – USPTO, 13% at WIPO. High patent activity has also been found in patent offices in Japan (JPO), Europe (EPO) and Canada (CIPO), where more than 6% of the patent applications were registered.

About 20% of scientific publications are registered in the Chinese online library of scientific publications CNKI. Also, a significant number of publications, in addition to those classified as generalized under Google, were published in the Wiley Online Library – 7.5%, OSTI (Office of Scientific and Technical Information, the U.S. Department of Energy) – approximately 6%, online library OnePetro (The Society of Petroleum Engineers) – more than 5% of those identified. The most popular resources were Marine and Petroleum Geology; Journal of Asian Earth Sciences; Journal of Natural Gas Science and Engineering (Science Direct), Geochemistry, Geophysics, Geosystems; Chinese Journal of Geophysics (Wiley Online Library), Geoscience; Marine Geology & Quaternary Geology (CNKI), Energies (MDPI). Fig. 7 and 8 show diagrams of the distribution of the number of patent applications and scientific publications published by residents of different countries around the world. In the first case, the highest activity was shown by US residents, who registered more than 38% of all patent applications for the considered period of time; Chinese representatives prepared more than 27% of patent documents. In the second case, the largest number of applications and publications was made by representatives of China, who published 27.1% of all identified scientific publications, and US residents were second with 20.5%.

Fig. 7-8. The number of patent applications and scientific publications filed by residents of the countries of the world. Patent applications on the left, scientific publications on the right.

Source: Advanced Energy Technologies

The top 10 patenters also included residents of Japan, the Netherlands, Norway, South Korea, France, Britain, Canada and Germany. Representatives of other countries accounted for just over 5% of patent applications. Non-residents registered the largest number of patent applications in absolute terms with the Canadian Patent Office – more than 85 or 91% of the total. Between 97 and 100% of patent documents were registered by non-residents in patent offices at IP Australia, the Mexican Institute of Industrial Property, and the National Institute of Industrial Property. Representatives from 17 countries filed applications to the US Patent Office, representatives from 8 countries to CNIPA (China), EPO and KIPO (S.Korea), and six countries to JPO (Japan).

The list of the top 10 countries whose residents published the largest number of scientific research results almost completely coincides with that for patent applications, with the exception of France and South Korea, whose places were taken by representatives of India and Russia. The share of publications attributable to residents of other countries is much higher here – 16%.

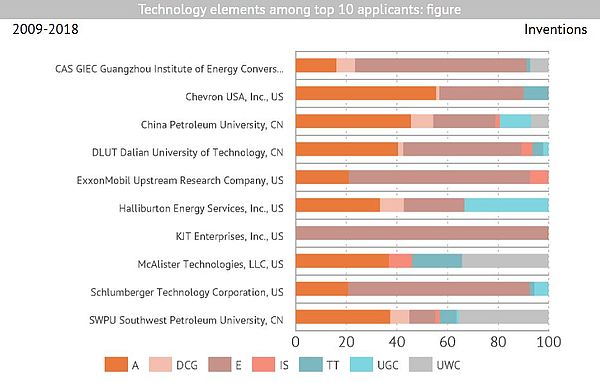

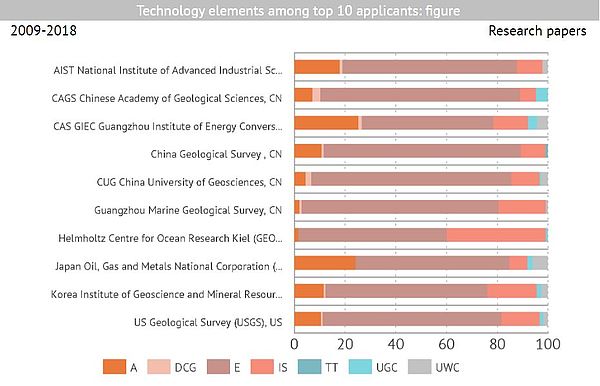

The priorities of the authors differed markedly when considering the issues that were raised in the analyzed documents (Fig. 9 and 10).

Fig. 9-10. Problems addressed in patent applications (left) and scientific publications (right)

LEPP – Low efficiency of primary processes; LESP – Low efficiency of secondary processes; LEEF – Low efficiency of exploration and forecasting; LEG – Low efficiency in general; HAPC – High additional production costs; HCD – High CAPEX/Development; HCE – High CAPEX/Exploration; HCG – High CAPEX in general; HCPM – High CAPEX / Preventive measures; HOG – High OPEX in general; HOM – High OPEX/Maintenance; CISP – Clathrate-induced seismic processes; CRI – Clathrate release impact on climate; NEP – Natural environment protection measures; SHT – Safety and health threats; AOP –Administrative and organisational problems; UP- Unclear problem;

Source: Advanced Energy Technologies

In patent applications, the authors most often addressed the issues of Low efficiency of primary processes and Low efficiency of exploration and forecasting (together – more than 40% of cases of references in patent documents). In addition, a significant number of patent solutions were aimed at solving the problems of High additional production costs, Natural environment protection measures, Clathrate-induced seismic processes and High CAPEX / Development. The share of documents in which it was not possible to recognize the problem, or those related to interpretations that went beyond the above list (Unclear problem) amounted to 7.1%. In the case of scientific publications, the authors primarily addressed the High CAPEX / Exploration issues that were mentioned in more than 52% of publications, as well as the problems of Clathrate release impact on climate and Clathrate-induced seismic processes – a joint mention in more than 25% of documents. The share of the Unclear problem was significantly less than 1%.

Technological aspects of activation and exploration of accumulations of methane hydrates prevailed in patent applications, in comparison with other aspects of the general technological chain of methane production from hydrates (Fig. 11). At the same time, the share of Activation technology in patent documents exceeded 37%, and Exploration – 30%. In addition, inventors quite often addressed issues related to Underwater drilling or capture (12.2% of cases mentioned). A completely different picture emerged when considering technological issues in the analysis of scientific publications. Here, in 63% of cases, the authors considered Exploration, and in almost 24% of cases, aspects of Infrastructure & security were mentioned (Fig. 12).

Fig. 11-12. The most popular technological processes among the authors of patent applications (left) and scientific articles (right)

A – Activation; DCG – Drilling or capture in general; E – Exploration; IS – Infrastructure & security; TT – Treatment & transportation; UGC – Underground drilling or extraction; UWC – Underwater drilling or capture

Source: Advanced Energy Technologies

When considering technological options for the activation of methane in gas hydrates and its release from the hydrate structure, the inventors and researchers were also not unanimous (Figs. 13 and 14). If in the first case the authors considered technologies tested in real conditions, such as Chemical activation (5.1% of patent applications mentioned this), Thermal activation (16.3%), Depressurization (6.9%), Injection and displacement (8.3%), but in scientific publications the authors mainly considered options other than those listed above – Unspecified technology (more than 85% of cases). The only widely accepted method that found significant interest among researchers was the Depressurization method, which was mentioned in 7.2% of publications.

Fig. 13-14. Correlation of the focus of the inventors and authors of scientific publications to methane activation technologies in hydrates (patent documents on the left and scientific publications on the right)

CA – Chemical activation; DS – Depressurization; ID – Injection and displacement; OP – Other physical actions; TA – Thermal activation; UT – Unspecified technology; BA – Biological activation

Source: Advanced Energy Technologies

The leaders in the number of registered patent applications were such American companies as Chevron USA, Inc. and Halliburton Energy Services (table 1), and their total share in the register of intellectual property on this subject for the period under review amounted to almost 15%. ExxonMobil Upstream Research Company and SWPU Southwest Petroleum University each filed more than 60 patent applications. The top 10 applicants included representatives from the USA and China in equal parts.

Table 1. Top 10 Applicants by Number of Registered Patent Applications

| Status | Country | Name | Average rating | Total 2009-2018 |

|---|---|---|---|---|

| Company | US | Chevron USA, Inc. | 13.4 | 120 |

| Company | US | Halliburton Energy Services, Inc. | 12.2 | 108 |

| Company | US | ExxonMobil Upstream Research Company | 13.3 | 68 |

| Organization | CN | SWPU Southwest Petroleum University | 11 | 61 |

| Organization | CN | CAS GIEC Guangzhou Institute of Energy Conversion | 12.3 | 39 |

| Company | CN | Daging Dongyou Ruijia Petroleum Tech Co Ltd | 12.5 | 37 |

| Company | US | McAlister Technologies, LLC | 10.7 | 32 |

| Organization | CN | China Petroleum University | 11.6 | 31 |

| Company | US | KJT Enterprises, Inc. | 12.4 | 30 |

| Organization | CN | DLUT Dalian University of Technology | 13 | 28 |

Source: Advanced Energy Technologies

Table 2. Top 10 organizations or companies with the largest number of scientific articles

| Status | Country | Name | Total 2009-2018 |

|---|---|---|---|

| Organization | CN | Guangzhou Marine Geological Survey | 210 |

| Organization | CN | CUG China University of Geosciences | 154 |

| Organization | US | US Geological Survey (USGS) | 120 |

| Organization | CN | CAGS Chinese Academy of Geological Sciences | 107 |

| Organization | CN | CAS GIEC Guangzhou Institute of Energy Conversion | 105 |

| Organization | DE | Helmholtz Centre for Ocean Research Kiel (GEOMAR) | 95 |

| Organization | KR | Korea Institute of Geoscience and Mineral Resources (KIGAM) | 95 |

| Organization | CN | China Geological Survey | 88 |

| Company | JP | Japan Oil, Gas and Metals National Corporation (JOGMEC) | 76 |

| Organization | JP | AIST National Institute of Advanced Industrial Science and Technology | 72 |

Source: Advanced Energy Technologies

The main technological focus of top 10 companies and organizations reflected in patents and scientific publications can be seen in Fig. 15 and Fig. 16.

Fig. 15. The most popular technological processes among the top 10 patent applicants

Source: Advanced Energy Technologies

Fig. 16. The most popular technological processes among the top 10 organizations and companies by the number of scientific publications

Source: Advanced Energy Technologies

Trends of development

Among the issues related to the future development of methane hydrate production technologies most of the interested parties have to face are twofold – if there are any prospects for industrial development of methane production from hydrates and when this can happen. However, finding an unequivocal and reasonable answers to these questions is not easy. Successful field trials conducted by Japanese and Chinese experts in 2017 inspire confidence that the era of gas hydrates, as a new energy resource, will come soon [21].

Moreover, based on the results of these tests, encouraging statements have been made by officials. For example, according to [38-39] it follows that Chinese officials hope that commercial production of methane from hydrates will begin by 2030, and Japanese officials believe that this will happen even earlier – between 2023 and 2027. Even more specific data are presented in the report [40], where it is assumed that by 2025 the market for methane production from hydrates will exceed 60 million m3, and its growth will begin in 2021 with an average of more than 6% per year. Of course, these are serious figures, and if implemented, the fact of industrial production of this type of methane would be confirmed.

However, a number of factors hold back this optimism. Firstly, while relatively successful mining experiments remain isolated cases, production volumes are too small to indicate the industrial readiness of technologies, and there are no reports of all necessary and precisely designed technological processes. In addition, many gaps remain in the methods of exploration of gas hydrate reservoirs and reliable determination of their characteristics. Serious fears are also caused by possible negative environmental consequences, which can be amplified many times because of any technological failures during the operation of hydrate deposits.

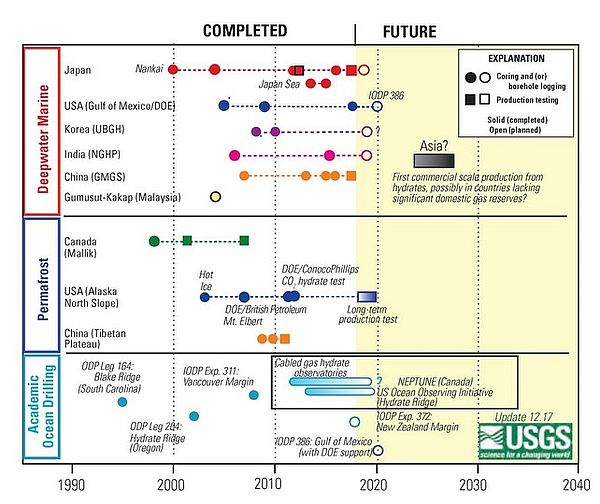

Research programs for studying gas hydrate accumulations and experimental technologies conducted by interested countries of the world are more predictable. Figure 17 shows a graph of a number of such programs published by the U.S. Geological Survey [41].

Fig. 17. Timeline showing past and future drilling and deep-sea coring and borehole logging expeditions as of late 2017

Source: U.S. Geological Survey (Public domain)

More detailed information about the conducted and planned research programs can be found on the following websites [42-50].

References

[1] Beaudoin, Y. C., Waite, W., Boswell, R. and Dallimore, S. R. (eds), 2014. Frozen Heat: A UNEP Global Outlook on Methane Gas Hydrates. Volume 1-3. United Nations Environment Programme, GRID-Arendal / www.netl.doe.gov/sites/default/files/netl-file/gas-hydrate-global-assessment-volume-1%5B1%5D.pdf

[2] Gas Hydrate in Nature/Fact Sheet 2017–3080, January 2018 /U.S. Department ofthe Interior/ U.S. Geological Survey/ pubs.usgs.gov/fs/2017/3080/fs20173080.pdf

[3] Gas hydrates/National Energy Technology Laboratory /United States Department of Energy / netl.doe.gov/oil-gas/gas-hydrates

[4] Where are gas hydrates found?/U.S. Geological Survey / www.usgs.gov/faqs/where-are-gas-hydrates-found

[5] The interaction of climate change and methane hydrates / Carolyn D. Ruppel and John D. Kessler / US Geological Survey/ Woods Hole, Massachusetts, USA, Department of Earth and Environmental Sciences, University of Rochester, Rochester, New York, USA/ agupubs.onlinelibrary.wiley.com/doi/epdf/10.1002/2016RG000534

[6] Marine Methane Hydrate Field Research Plan/ Consortium for Ocean Leadership and the Methane Hydrate Project Science Team December 2013/ National Energy Technology Laboratory/ Award Number: DE-FE0010195/ United States Department of Energy / oceanleadership.org/wp-content/uploads/2013/01/MH_Science_Plan_Final.pdf

[7] METHANE HYDRATE SCIENCE AND TECHNOLOGY: Science and Technologies/ Evaluating the resource potential of methane hydrate and understanding its role in global climate change/ A 2017 UPDATE / National Energy Technology Laboratory/ United States Department of Energy / netl.doe.gov/sites/default/files/netl-file/2017-Methane-Hydrate-Primer%5B1%5D.pdf

[8] Energy Resource Potential of Methane Hydrate/ February 2011/ National Energy Technology Laboratory/ United States Department of Energy / www.netl.doe.gov

[9] ENERGY RESOURCES POTENTIAL OF METHANE HYDRATE AS POTENTIAL FUEL SOURCE 2015/Ab. Rauf, Faisal H, Assaduallah M./ 2015 International Field Exploration and Development Conference (IFEDC 2015) / www.researchgate.net/publication/301440976_Energy_resources_potential_of_methane_hydrate_as_potential_fuel_source

[10] Boswell, R., and Collett, T.S., 2011, Current perspectives on gas hydrate resources: Energy & Environmental Science, v. 4, p. 1206–1215. / doi.org/10.1039/C0EE00203H

[11] GLOBAL RESOURCE POTENTIAL OF GAS HYDRATE – A NEW CALCULATION /Arthur H. Johnson /Hydrate Energy International /Kenner, Louisiana, UNITED STATES / www.pet.hw.ac.uk/icgh7/papers/icgh2011Final00070.pdf

[12] Global Resource Potential of Gas Hydrate – A New Calculation/ By Arthur H. Johnson (Hydrate Energy International)/ Fire in the Ice/ Methane Hydrate Newsletter /Vol. 11, Issue 2/ National Energy Technology Laboratory / United States Department of Energy /

www.netl.doe.gov

[13] Assessment of In-Place Gas Hydrate Resources of the Lower 48 United States Outer Continental Shelf/ BOEM Fact Sheet RED-2012-01 / Bureau of Ocean Energy Management/ www.boem.gov/sites/default/files/uploadedFiles/BOEM/Oil_and_Gas_Energy_Program/Resource_Evaluation/Gas_Hydrates/BOEM-FactSheetRED_2012-01.pdf

[14] Presentation on Natural Gas Hydrate Exploration /National Energy Technology Laboratory / United States Department of Energy / www.netl.doe.gov/File%20Library/research/Oil-Gas/methane%20hydrates/MHNews-2011-12.pdf

[15] GAS HYDRATES Taking the heat out of the burning-ice debate Potential and future of Gas Hydrates/ SBC Energy Institute / June 2015/ www.sbc.slb.com/SBCInstitute

[16] Japan’s Methane Hydrate R&D Program Progresses to Phase / Yoshihiro Masuda, Koji Yamamoto, Shimada Tadaaki, Takao Ebinuma, Sadao Nagakubo/ The University of Tokyo, Japan Oil, Gas and Metals National Corporation, National Institute of Advanced Industrial Science and Technology, MH21 Research Consortium Japan/ netl.doe.gov/sites/default/files/netl-file/MHNewsFall09.pdf

[17] Gas Hydrate Prospecting and Characterization / Daniel Russell McConnell(Fugro) / Offshore Technology Conference, 6-9 May, Houston, Texas, 2019/ www.onepetro.org/conference-paper/OTC-29604-MS

[18] Review of exploration and production technology of natural gas hydrate/ Yudong Cui, Cheng Lu, Mingtao Wu, Yue Peng, Yanbin Yao, Wanjing Luo, School of Energy Resources, China University of Geosciences, Beijing 100083, P. R. China, The Key Laboratory of Unconventional Petroleum Geology, China Geological Survey, Beijing 100029, P. R. China/ www.yandy-ager.com/index.php/ager/article/view/19/13

[19] Drilling of gas hydrate reservoirs/ Sükrü Merey/ Journal of Natural Gas Science and Engineering 35, September 2016/ www.researchgate.net/publication/308539337_Drilling_of_Gas_Hydrate_Reservoirs

[20] GAS HYDRATE ACCUMULATION TYPES AND THEIR APPLICATION TO NUMERICAL SIMULATION/Ray Boswell, U.S. Department of Energy, National Energy Technology Laboratory Morgantown USA; George Moridis, Matthew Reagan, Lawrence Berkeley National Laboratory, Berkeley, USA; Timothy S. Collett, U.S. Geological Survey, Denver, USA/ Proceedings of the 7th International Conference on Gas Hydrates (ICGH 2011),Edinburgh, Scotland, United Kingdom, July 17-21, 2011/ pdfs.semanticscholar.org/8d3e/4703fa6ae3d2e925b79df36130b7e9e6a1b6.pdf

[21]The first offshore natural gas hydrate production test in South China Sea/ Jin-faLi, Jian-liang Ye, Xu-wen Qin, Hai-jun Qiu, Neng-you Wu, Hai-long Lu, Wen-wei Xie, Jing—an Lu, Fei Peng, Zhen-qiang Xu, Cheng Lu,Zeng-gui Kuang, Jian-gong Wei, Qian-yong Liang, Hong-feng Lu, Bei-bei Kou/ China Geology, Volume 1, Issue 1, March 2018, Pages 5-16/ www.sciencedirect.com/science/article/pii/S209651921930014X

[22] Japan extracts gas from methane hydrate in world first/12 March 2013/ BBC / www.bbc.com/news/business-21752441

[23] Distribution of gas hydrate reservoir in the first production test region of the Shenhu area, South China Sea/ lRu-wei Zhanga, Jing-anLua, Pen-feiWena, Zeng-gui Kuanga, Bao-jin Zhanga, HuaXuea, Yun-xia Xua, Xi Chena/ China Geology, Volume 1, Issue 4, December 2018, Pages 493-504/ www.sciencedirect.com/science/article/pii/S2096519219300783

[24] Construction Process of a Low-Cost Subsea Well for Methane Hydrate Production in Nankai Trough /Marcio YAMAMOTO, Kazuo MIURA/The 27th Ocean Engineering Symposium, conference paper/8 August 2018/7 р./ www.researchgate.net/profile/Marcio_Yamamoto2/project/Subsea-Well-Design-for-Methane-Hydrate-Production/attachment/5b696bae3843b04aed78e4d8/AS:656929063989257@1533635502445/download/OES27_041.pdf

[25] Optimal design of the engineering parameters for the first global trial production of marine natural gas hydrates through solid fluidization /Shouwei Zhou, Jinzhou Zhao, Qingping Li, Wei Chen, Jianliang Zhou, Na Wei, Ping Guo, Wantong Sun/Natural Gas Industry B, Volume 5, Issue 2, article/March 2018/Pages 118-131/ www.sciencedirect.com/science/article/pii/S2352854018300044

[26] Numerical Investigation of Hydrate Dissociation Performance in the South China Sea with Different Horizontal Well Configurations /Jing-Chun Feng, Xiao-Sen Li, Gang Li, Bo Li, Zhao-Yang Chen, Yi Wang/Energies, 7(8), article/28 July 2014/pp. 4813-4834/ www.mdpi.com/1996-1073/7/8/4813

[27] Evolution of Hydrate Dissociation by Warm Brine Stimulation Combined Depressurization in the South China Sea /Jing-Chun Feng, Gang Li, Xiao-Sen Li, Bo Li, Zhao-Yang Chen/Energies , 6(10), article/21 October 2013/pp. 5402-5425/ www.mdpi.com/1996-1073/6/10/5402

[28] Polyethylene Glycol Drilling Fluid for Drilling in Marine Gas Hydrates-Bearing Sediments: An Experimental Study /Guosheng Jiang , Tianle Liu, Fulong Ning, YunzhongTu, Ling Zhang, Yibing Yu, Lixin Kuang/Energies , 4(1), article/19 January 2011/pp. 140-150/ www.mdpi.com/1996-1073/4/1/140

[29] Modeling the injection of carbon dioxide and nitrogen into a methane hydrate reservoir and the subsequent production of methane gas on the North Slope of Alaska /Garapati, N., McGuire, P.C., Liu, Y., and Anderson, B.J./ Unconventional Resources Technology Conference, conference paper/2013/10 p./ library.seg.org/doi/abs/10.1190/urtec2013-199

[30] Replacement of CH4 with CO2 in a hydrate reservoir at the injection of liquid carbon dioxide /N. G. Musakaev, M. K. Khasanov, M. V. Stolpovsky/AIP Conference Proceedings, Volume 2027, Issue 1, conference paper/December 2018/7 р./ aip.scitation.org/doi/abs/10.1063/1.5065145

[31] Methane Recovery from Natural Gas Hydrate in Porous Sediment Using Gaseous CO2, Liquid CO2, and CO2 Emulsion /Ying Wu, John J. Carroll, Qi Li, Sheng-li Li, Xiao-Hui Wang, Chang-Yu Sun, Qing-Yuan, Guang-Jin Chen/Gas Injection for Disposal and Enhanced Recovery, book chapter/12 September 2014/ onlinelibrary.wiley.com/doi/abs/10.1002/9781118938607.ch21

[32] CO2 injection into submarine, CH4-hydrate bearing sediments: geochemical implications of a hydrate conversion technology /C. DEUSNER, E. KOSSEL, N. BIGALKE, M.G. GHARASOO, AND M. HAECKEL /Goldschmidt2013 Conference Abstracts, conference paper abstract/2013/1 p./ oceanrep.geomar.de/26257/

[33] Study of effective parameters for enhancement of methane gas production from natural gas hydrate reservoirs /Hamid Aghajari, Moien Habibi Moghaddam, Mehdi Zallaghi/Green Energy & Environment, article/4 May 2018/ www.researchgate.net/profile/Mehdi_Zallaghi/publication/324955488_Study_of_Effective_Parameters_for_Enhancement_of_Methane_Gas_Production_from_Natural_Gas_Hydrate_Reservoirs/links/5bfe44a44585157b8172c04b/Study-of-Effective-Parameters-for-Enhancement-of-Methane-Gas-Production-from-Natural-Gas-Hydrate-Reservoirs.pdf

[34] Molecular dynamics simulations to study the effect of fracturing on the efficiency of CH₄-CO₂ replacement in hydrates /Aditaya O. Akheramka/University of Alaska Fairbanks, thesis/May 2018/134 р./ scholarworks.alaska.edu/handle/11122/8642

[35] Mathematical model of methane replacement process in gas hydrate with carbon dioxide in a porous layer /M. K. Khasanov, M. V. Stolpovsky, S. R. Kildibaeva/South Ural State University Bulletin, Mathematical Modelling, Programming & Computer Software, Vol. 10, Issue 4, article/December 2017/8 р./

cyberleninka.ru/article/n/17465613

[36] Gas production from marine gas hydrate deposits through depressurization and CO2 injection – novel test devices for studying sediment mechanical and hydraulic response and resolving mechanisms of yielding and sand production /Christian Deusner, Elke Kossel, Nikolaus Bigalke, Matthias Haeckel /GEOMAR Helmholtz Centre for Ocean Research, extended abstract/2015/3 p./ upcommons.upc.edu/bitstream/handle/2099/16645/IP_S4_2_Extended_Abstract_SEG2015_cdeusner.pdf

[37] Unconventional Oil & Gas Production/ IEA ETSAP - Technology Brief P02/ May 2010/ iea-etsap.org

[38] China extracts gas from 'flammable ice' mined from South China Sea/THE STRAITS TIMES/ MAY 19, 2017/ www.straitstimes.com/asia/east-asia/china-extracts-gas-from-flammable-ice-mined-from-south-china-sea

[39] Japan reports successful gas output test from methane hydrate/Reuters/ MAY 8, 2017/ www.reuters.com/article/japan-methane-hydrate-idUSL4N1IA35A

[40] Methane Hydrate Extraction Market: Opportunity Analysis and Industry Forecast, 2021–2025 /May 2019/ www.reportlinker.com/p05793184/Methane-Hydrate-Extraction-Market-Opportunity-Analysis-and-Industry-Forecast-.html

[41] Modern Perspective on Gas Hydrates USGS/ Release Date: March 8, 2018/U.S. Geological Survey / www.usgs.gov/news/modern-perspective-gas-hydrates

[42] U.S. Geological Survey Gas Hydrates Project/ www.usgs.gov/centers/whcmsc/science/us-geological-survey-gas-hydrates-project

[43] Gas hydrates/National Energy Technology Laboratory / United States Department of Energy / www.netl.doe.gov/oil-gas/gas-hydrates

[44] A Review of the Methane Hydrate Program in Japan - MDPI /A Oyama, 2017Research Consortium for Methane Hydrate Resources in Japan (MH21)/ www.mh21japan.gr.jp/english/about-this-site/

[45] GEOMAR Helmholtz Centre for Ocean Research Kiel/ www.geomar.de/en/centre/

[46] Guangzhou Marine Geological Survey (GMGS)/ www.hydz.cn/about.html

[47] The Centre for Arctic Gas Hydrate, Environment and Climate (CAGE)/ cage.uit.no/about-us/

[48] National Gas Hydrate Programme (NGHP)/ www.oidb.gov.in/index1.aspx

[49] Marine gas hydrate - an indigenous resource of natural gas for Europe (MIGRATE)/ www.migrate-cost.eu/home

[50] Korea Institute of Geoscience and Mineral Resources (KIGAM)/ www.kigam.re.kr/english/