Once upon a time, Volkswagen made the most powerful and fastest production car - the Bugatti Veyron EB 16.4. The objective behind Volkswagen XL1 was completely different – develop the most environmentally friendly hybrid car and hopefully slightly less expensive than Bugatti.

Like the Bugatti Veyron, the XL1 owes its existence to Ferdinand Piëch, grandson of Ferdinand Porsche and chairman of the executive board of Volkswagen Group during 1993–2002 and chairman of the supervisory board of Volkswagen Group during 2002–2015.

This visionary gentleman was not afraid to experiment. And although some of his projects didn't quite work out, or cost the car company a lot of money, there is definitely something to remember.

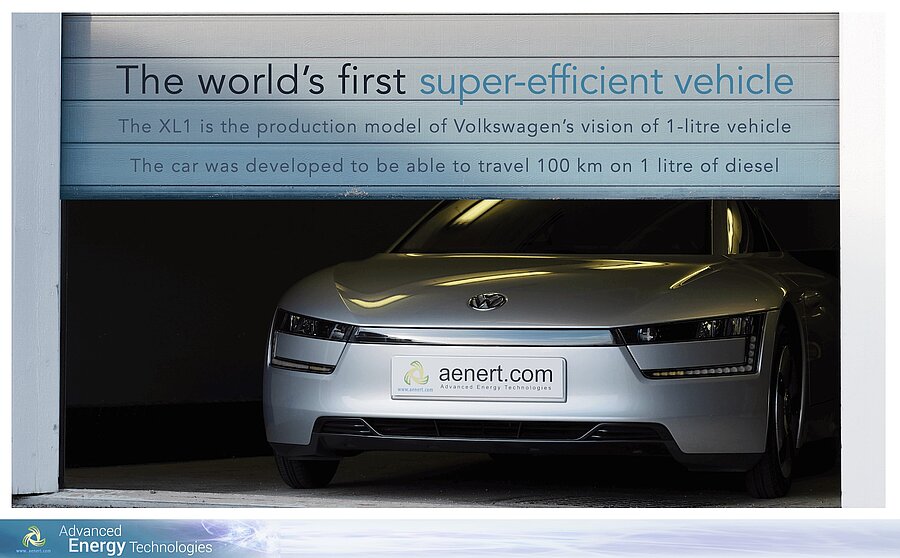

Ferdinand Piëch set himself a much more ambitious goal in 2001. Build a full-fledged car for everyday use that can carry two adults and their luggage and can do it for a hundred kilometres on a litre of fuel.

XL1 served to redefine the Volkswagen brand as the forefront of an economical and efficient future. At the start of the new millennium, it looked like the future belonged to diesel. The Volkswagen Group used diesel engines in practically everything, from luxury sedans to small hatchbacks and truly sporty (Audi R10 TDI LeMans) cars. So it was a no-brainer that the economical novelty would also burn diesel.

The first concept was presented already in 2002. It was an utopian "concept" - a streamlined tandem Volkswagen 1-Liter car weighing 290 kg with a single-cylinder three-hundred-cube diesel engine (8.5 hp). Piëch personally drove it from Wolfsburg to Hamburg to the annual meeting of shareholders of VAG, Volkswagen Audi Group - and the idea seemed to be forgotten.

It was given the not very original name 1L, a three-cylinder single-cylinder with a power of six kilowatts and direct injection located at the rear above the axle and a six-speed automatic. The resulting creation looked rather comical and was quite far from a normal car. It only had one small flaw. The 1L cleverly combined the disadvantages of a car and a motorcycle, but it was insanely expensive and slow. As a development exercise, it may have held up, but there would probably be almost no one who would actually buy such a "car". So, it was necessary to go back to the drawing board and turn the strange blob into something that would have a chance to succeed in the real world.

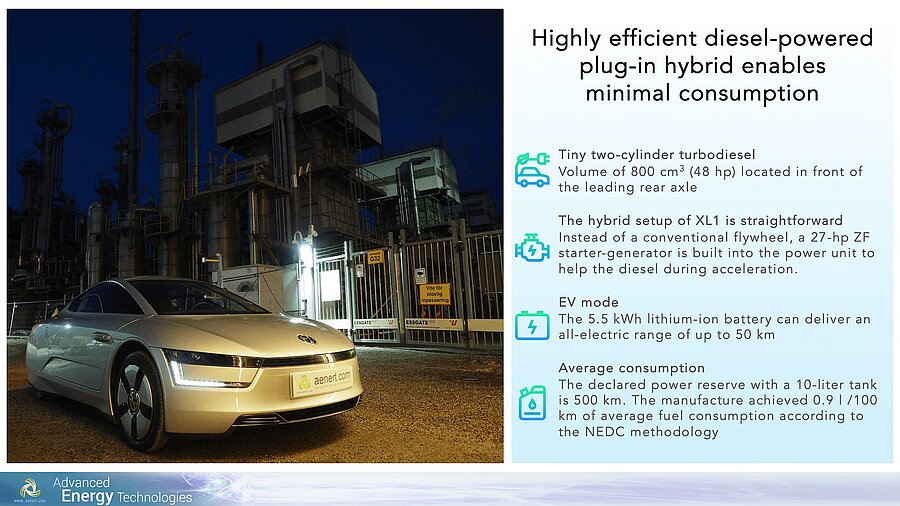

In June 2009, Volkswagen finalized the development of the very economical model with again “original” name L1. Compared to the previous 1L, it was a big step forward. Half of a turbodiesel four-cylinder one-six moved in under the hood, a turbocharged 800 cc two-cylinder tuned to 29 kW coupled with a 10 kW electric motor and Li-ion batteries. The drivetrain offered quite satisfactory dynamics - the maximum speed was 160 km/h, and the L1 accelerated from zero to 100 km/h in eleven seconds.

But all this brought with it an unpleasant fact - the L1 no longer drove for that mythical litre per hundred, the official value moved to 1.49, but tests in operation showed more values around two-litre consumption. Which is not bad at all, but for something that has the number one in the name, it still seems a bit out of place.

Volkswagen has promised that the serial version will return to the value of less than a litre per hundred. But because of this, the promised start of sales was postponed till summer of 2013.

The constant postponement of the production of the "litre" car had a rather unpleasant effect on investors and potential customers. Opinions appeared more and more often that the car would never make it into production.

Gladly, just 2 years later, in 2011, at the Qatar Motor Show in Doha, the Volkswagen XL1 was shown to the world.

- The novelty abandoned the impractical sitting behind one another in a row and placed the passengers classically one next to the other.

- The width was comparable to ordinary compact cars

- Instead of an opening glass dome, there were a pair of folding, but much more conventional doors.

- The interior finally began to resemble a normal car and not an advertisement for discomfort.

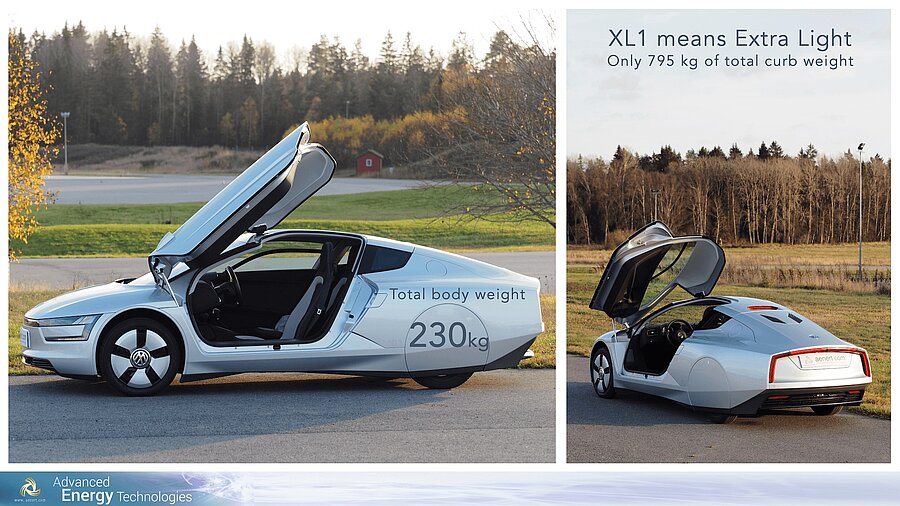

Weight - that's was declared the number one enemy for the responsible project development team, with whom they fought resolutely and mercilessly! XL1 means Extra Light - only 795 kg curb weight, almost like a Smart minicar.

The car looked great, futuristic and attracted a lot of interest. Despite the ambitious price tag of 111,000 EUR, all cars were quickly sold out in pre-orders. Its production was extremely demanding, most of the car was built by hand. The production of 250 cars took more than two and a half years, the last piece was delivered to the customer in August 2016. Of the 250 units produced, 50 were not sold to retail customers and remained in VW’s ownership.

The technology is truly supercar!

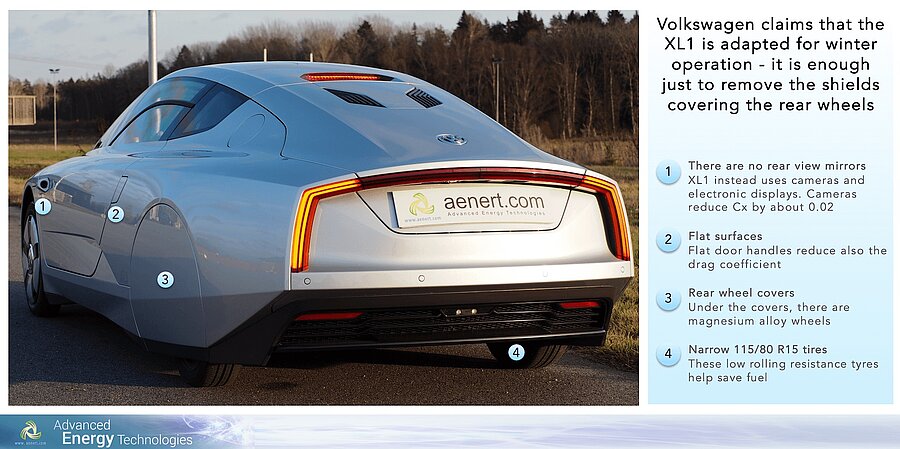

And it’s not just about the shape of the body with a height of only 1153mm (lower than many Lamborghini models) and the unrealistically low coefficient of aerodynamic drag Cx = 0.189, for which, among other things, Volkswagen had to sacrifice rear-view mirrors, narrow the back like a fish and “shod” XL1 with wheel covers and motorcycle-sized wheels.

The digital exterior mirrors represented a technical breakthrough on an international scale back in 2012. The cameras and monitor system made XL1 as the first eligible car for certification under the German Road Traffic Ordinance. The so-called “e-mirrors” indeed offer potential for energy and emissions savings through improved aerodynamics, and on the other hand it ensures increased road safety in difficult lighting conditions.

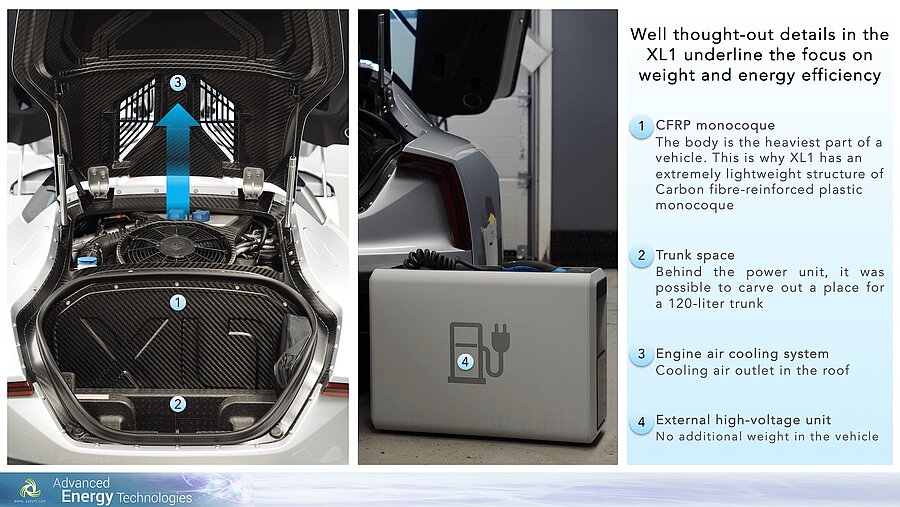

The basis of the body is a carbon fibre-reinforced plastic monocoque, to which the power unit and suspension are attached to the aluminium subframes in front and rear. The Lamborghini Aventador is built exactly in the same way. If for Lamborghini the Austrian company Carbo Tech Composites (CTC) helped to develop just the monocoque technology, which is known as aRTM (Аdvanced Resin Transfer Moulding), then for the XL1 it even manufactured the monocoques.

In contrast to the limited production technology Prepreg (Pre-impregnated), when the matrices of body parts are laid out with adhesive and resin-impregnated mats, with aRTM technology, parts are produced in multi-shell, heated and vacuum-sealed tools. This involves injecting liquid resin at high pressure into the tool containing the semi-finished carbon material whose interior has the shape of the part to be produced.

This requires expensive equipment, but it comes out many times faster. But even with aRTM, there is no question of mass production. Back in 2013 in Salzburg, Austria, CTC could “bake” daily two to four monocoques for XL1 weighing 89 kg each, at possible cost of 30 thousand euros per monocoque!

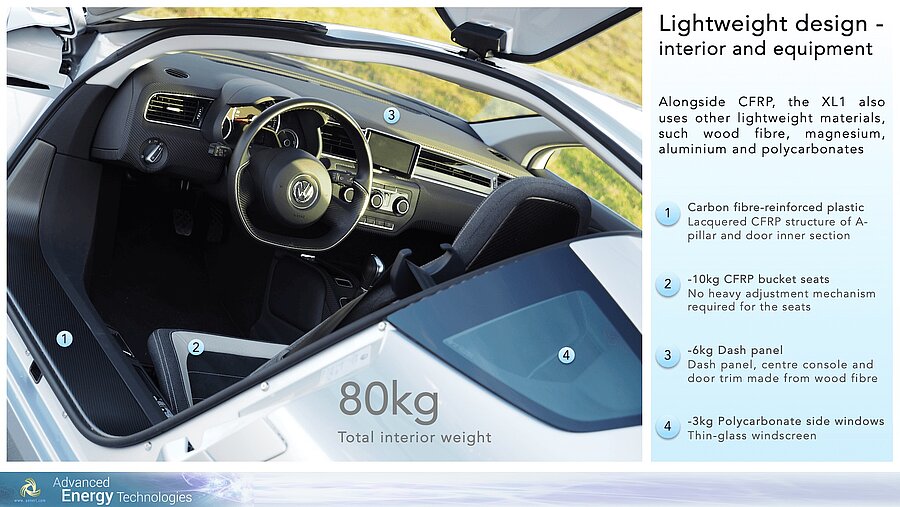

Every gram counted!

The Germans allocated 80 kg to the entire interior trim with a central panel made of cellulose weighing 3409 grams and six-kilogram carbon-fibre buckets of Sparco chairs.

The running gear also uses high-quality materials and low-volume production methods. The total chassis weight is just 153 kg. Power steering with 115 mm wide wheels is not needed, which saves 10 kg. Not a single suspension part, including aluminium hubs, levers, brake callipers and shock absorbers, magnesium alloy wheels, plastic stabilizers and carbon composite brake discs, does not weigh more than two or three kilograms.

All electrics, together with a 70-kilogram Sanyo battery with a capacity of 5.5 kWh of 60 lithium-ion cells, fit into 105 kg.

The drive system has also received modifications during the 10-year development:

- The battery got a higher capacity, so it was possible to drive up to 50 kilometres purely on electric power.

- The two-cylinder diesel was able to be tuned a little more happily, in addition, this diesel boasted excellent emission values and fulfilled the Euro6 standard without any problems. Like all Volkswagen diesels at the time. Almost as if it were some kind of magic. The magic with emissions, which has a special place in the Dieselgate scandal.

The official consumption value in the company materials is 0.9 l/100 km. For a car twice as heavy than the initial 1L concept, this was a tremendous achievement. Realistically the XL1 owners over the years are able to achieve a consumption of around 2-2.5 litres per hundred kilometres during normal driving conditions. These are also very nice numbers, which the vast majority of ordinary cars have no chance of achieving.

VW built such a low number of XL1s and the people who own them tend to be devoted about them, so they rarely come up for sale.

XL1 has become a collector's item rather than a means of personal transport. Especially when very similar consumption could be achieved with the much more conventional and practical Lupo 3L model, or Audi A2 3L, which cost a fraction of the price.

In the end, the Volkswagen XL1 is rather a kind of moving monument, a memory of the visionary mind of Ferdinand Piëch and the time when we thought that the ecological future belonged to diesel.

Text and photos by Ion Ciorici