Nowadays a trend can be witnessed in almost all countries around the globe which focuses on the development of renewable energy sources. One condition that has to be met in order to efficiently harness the energy produced by renewables is that the storage media or batteries have to be more flexible and enduring. There are a great many companies dedicated to producing batteries with higher energy density, lighter weight, faster recharge times, and less reliance on mining of rare metals. The latter is of great importance as lithium, which is used in lithium-ion batteries, the current market leader, is not readily-available everywhere.

The other challenge in the production of lithium-ion batteries is the use of graphite. Graphite is a fossil carbon. Therefore, it is either mined or derived from other fossil-based materials. Extraction through mining often does a lot of harm to the environment, which also has dire consequences for human society.

Now (2022), two companies, Northvolt and Stora Enso, have entered into a joint venture to create batteries using lignin-based hard carbon generated by renewable wood from Nordic forests. Their aim is to design the first battery whose anode is made up of materials produced entirely in Europe. As a result, the cell would be both low-cost and more environmentally-friendly.

The main component in these batteries is wood-based lignin. Lignin is a polymer which can be obtained from the cell walls of dry-land plants. Trees are made up of 20–30% lignin, which is a strong, natural binding agent. Lignin is considered by some to be one of the largest renewable sources of carbon.

Stora Enso has been engaged in industrialised production of lignin at a production site in Finland since 2015. At the moment, its annual production capacity amounts to 50,000 tons, which makes it the largest lignin producer worldwide. The biomaterial production line for the wood battery currently exists only as a pilot project, but the company is conducting a feasibility study at the moment to analyse the scale of the industrial production of the battery.

Northvolt, meanwhile, began its first cell production at its gigafactory located in Sweden. The company aims to extend its profile and build a second gigafactory until 2025, and a third one in Germany, which was announced in March 2022. Now, with the help of Stora Enso, Northvolt is turning to the Nordic woods to develop wood-based batteries. Apart from developing wood-based batteries, Northvolt is also making an effort to produce batteries from sustainable materials, such as 100% recycled nickel, manganese, and cobalt.

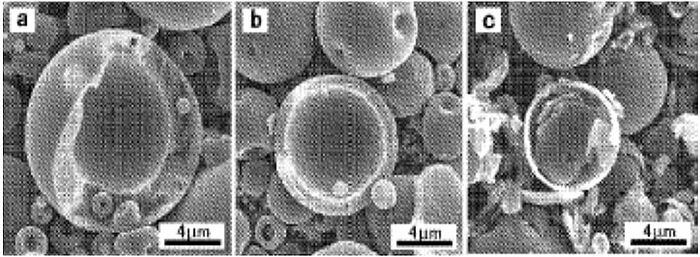

For many years, scientists have tried to improve or find alternatives to the commonly-used lithium-ion batteries. In 2020, scientists developed a method which enabled preparing a carbon microparticle from an organic raw material whose main component was lignin, as well as a carbon microparticle obtained by this method. An aqueous solution with a total concentration of lignin and sodium hydroxide amounting to 5 % (the proportion in mass is 1:0.5) was spray-dried to prepare a complex microparticle. The microparticle was then heat-processed under nitrogen atmosphere at 600°C. for one hour and let to cool. Afterwards, it was washed with water and further dried to prepare a hollow carbon microparticle. The prepared carbon microparticle was light-weight and has an equivalent specific surface area to commercially available activated charcoal.

Image: Prepared hollow carbon microparticle

Source: US20100304141A1

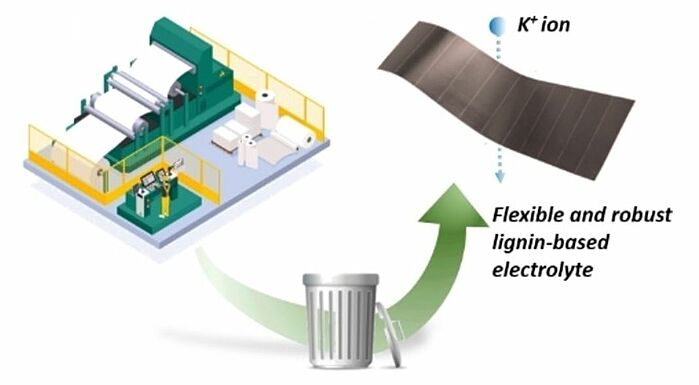

In 2022, a lignin-based membrane was developed by crosslinking a pre-oxidized Kraft lignin matrix - which was derived from treating wood chips with a hot mixture of water, sodium hydroxide (NaOH), and sodium sulphide (Na2S), known as white liquor, that breaks the bonds that link lignin, hemicellulose, and cellulose - with an ethoxylated difunctional oligomer, producing self-standing membranes that contained solvated potassium salts and showed a wide stability window and ionic conductivity. Battery prototypes had an initial specific capacity of 168 mAh g−1 at 0.05 A g−1 and stability for more than 200 cycles. When potassium metal cell prototypes were assembled, the lignin-based electrolyte reached significant electrochemical performances and an excellent operation for more than 200 cycles, which was an excellent result for biosourced systems in potassium batteries.

Image: Lignin-based membrane

Source: Sabrina Trano, Francesca Corsini, Giuseppe Pascuzzi, Elisabetta Giove, Dr. Lucia Fagiolari, Dr. Julia Amici, Prof. Carlotta Francia, Prof. Stefano Turri, Prof. Silvia Bodoardo, Prof. Gianmarco Griffini, Prof. Federico Bella/ Lignin as Polymer Electrolyte Precursor for Stable and Sustainable Potassium Batteries/ ChemSusChem Volume 15, Issue 12, 01 April 2022/ doi.org/10.1002/cssc.202200294/ Open Source This article is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0)

There are many advantages involved in using lignin-based batteries: lignin-based hard carbon has the ability to secure the strategic European supply of anode raw material and thus provide battery applications for mobility as well as stationary energy storage. Furthermore, it contributes to expanding the European battery value chain, while also developing a less expensive battery chemistry. The battery demonstrates how a sustainable battery industry can help make a positive impact both on society and cost. Also, lignin is one of the biggest renewable sources of carbon available in many parts of the world.

The companies are convinced that a fully functional lignin-based battery has the capacity to charge at a faster rate than the fossil-fuel powered market leader and thus revolutionise the energy industry. In view of the current energy crisis, a lignin-based battery could make a great difference to the further development of the world economy.