Syngas is one of the key resources for the production of synthetic fuels. Hydrogen, which is a part of syngas is widely used in oil refining and ammonia production. One of the main advantages of syngas is that it can be produced from almost any hydrocarbon or organic material, including natural gas, oil, coal, biomass and even municipal waste. The feedstock is exposed to a high temperature and controlled composition of the gas mixture inside the reactor, which leads to the breakdown of the complex organic molecules into a mixture of elemental hydrogen and carbon monoxide.

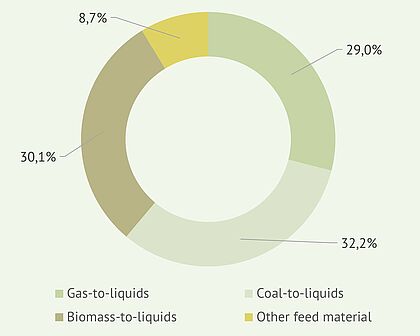

With the subsequent application of the Fischer-Tropsch process, high quality synthetic fuels are obtained. Each stage of the production, purification and use of synthesis gas requires careful consideration to issues of efficiency, safety and high cost of the production process, as well as product quality.

1. Natural gas production well (raw material for processing); 2. The gas purification from sulfur impurities or metals; 3. Synthesis reactor; 4. Fischer-Tropsch reactor; 5. Liquid hydrocarbons upgrading in to the final products. 6. Product storage; 7. Transportation of products

EnerTechUp company performed a systematic search of patent documents on this subject, prepared a unique patent database, and conducted a thorough statistical analysis of the patenting activity results.

The database includes more than 19.5 thousand patent documents published in generally-accessible sources all over the world during 1990 and 2022. General methodology of patent database compilation and statistical evaluation used in this product can be found at aenert.com.

Over the 20-year period (2002-2021), patenting activity in the field of syngas production has grown substantially and continues to remain on a high level. Since 2010, over two hundred patents are granted and several hundred patent applications are filed annually.

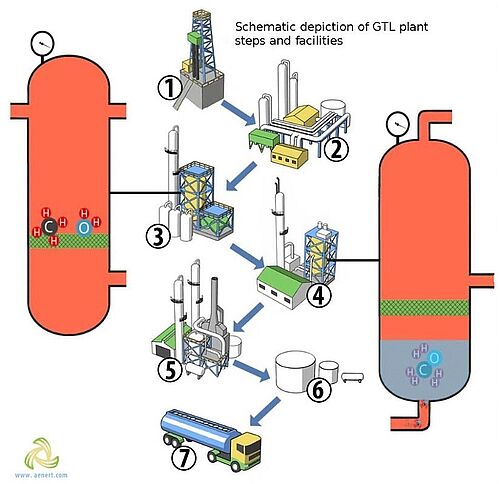

The most active registration of patent applications took place in 2014-2018. The most popular patent offices with applicants were USPTO (the United States), CNIPA (China), and EPO. Representatives of 57 countries around the world participated in the patenting process.

Countries participating in the patenting process. Patents, 2002-2021

The largest number of patents were granted to the residents of the United States, China, and Germany. The residents of China (30%) and the United States (19.5%) filed the largest number of patent applications in the last five years.

The leaders by the number of patents granted in the 20-year period were companies Shell Internationale Research Maatschappij B.V. (the Netherlands) and Haldor Topsoe A/S (Denmark) – 203 and 185 patents, respectively. L'air Liquide (France) registered the largest number of new patent applications during 2017-2021 – 172.

Top 10 applicants by intellectual property market involvement. Applications, 2017-2021

| Status | Country | Name | Volume ratio, % | Ownership ratio, % | Market involvement ratio, % |

|---|---|---|---|---|---|

| Company | FR | Air Liquide | 4.93 | 98.52 | 4.86 |

| Company | DK | Haldor Topsoe A/S | 4.47 | 98.40 | 4.40 |

| Company | CH | Casale S.A. | 2.18 | 100.00 | 2.18 |

| Company | NL | Shell Internationale Research Maatschappij B.V. | 1.86 | 89.23 | 1.66 |

| Company | DE | BASF, SE | 1.35 | 92.91 | 1.25 |

| Company | US | Praxair Technology Inc. | 1.20 | 98.94 | 1.14 |

| Company | CN | Xinjiang Guoliheng Clean Energy Technology Co. Ltd | 1.09 | 100.00 | 1.09 |

| Company | US | Gas Technology Institute | 1.12 | 96.67 | 1.08 |

| Company | FI | VTT Technical Research Centre of Finland | 0.95 | 100.00 | 0.95 |

| Company | CN | ENN Science & Technology Development Co Ltd | 0.95 | 97.98 | 0.93 |

Volume ratio - share of applicant documents in total number of documents.

Ownership ratio - applicant's participation share in total number of documents.

Market involvement ratio - volume ratio multiplied by ownership ratio.

The database includes a collection of patents and patent applications disclosing various aspects of syngas production.

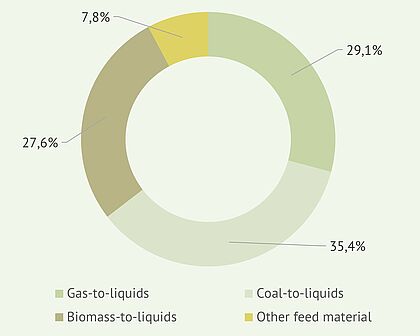

Depending on the type of feedstock used, the syngas production processes with a subsequent synthesis of liquid fuel were named Gas to liquid (GTL), Coal to liquid (CTL), Biomass to liquid (BTL). Each of these technologies has its own fundamental distinctive features, which often doesn’t allow them to be addressed collectively. Nevertheless, each of them is based on syngas production, which implies the involvement of related processes.

Breakdown of documents by technology categories. Patents, 2002-2021 (left), Applications, 2017-2021 (right), by the number of mentions in patent documents

In patents and patent applications, the technological categories Coal-to-liquids were most often mentioned. In the majority of cases the authors indicated Low efficiency of main processes and High OPEX / Maintenance as the problems the technical solutions disclosed in the patents and patent applications were aiming to solve. In the vast majority of cases, the inventions were related to devices or methods.

The production of liquid fuels from natural gas is a long-established industrial process.The largest plants, Pearl GTL and Oryx GTL, with a total capacity of 270,000 bpd, are located in Qatar, which has large natural gas reserves and is the largest producer of liquefied natural gas (LNG).

One scenario of implementing GTL technologies involves the use of specialized microchannel equipment. Microchannel technologies for the production of synthetic fuel are viewed primarily as the most promising options for the useful utilization of associated petroleum gas in oilfields.

Coal-to-liquid technologies enable producing high-quality synthetic fuel from coal, which is the cheapest type of fossil fuel. However, these technologies are characterized by low economic performance and environmental problems. Underground coal gasification is a kind of CTL technology where major high-temperature processes are performed directly in the coal beds, thus minimizing the costs related to expensive equipment and alleviating ecological impact.

The use of environmentally-friendly types of energy has led to an increased interest of modern society in various methods of renewable energy production, such as biomass gasification. A great variety of different biomass and waste-derived feedstocks are suitable for this process, including wood chips, waste wood, agricultural wastes, switch grass, and crop-related residues. This, however, can also cause problems because various feedstock needs various gasifier types and plant sizes. Different feedstock can also have different heating values and moisture content. During gasification, tar formation is one of the biggest issues which cause, for example, equipment blocking, poor quality gas output and increased maintenance. Environmental issues surrounding biomass gasification include the emission of toxic gases, such as CO, Six, NOx.

A detailed statistical and technological analysis of patent documents related to syngas production was conducted for individual patent groups containing documents with similar technological attributes. The groups were selected on a trade-off basis, taking into consideration the technological importance of a subject, its popularity with inventors, the possibility of unambiguous interpretation of technological attributes of a group, and reasonable number of the groups. List of individual patent groups includes: “Feedstock preparation”, “Syngas production in general”, “Primary technologies of syngas production”, “Microchannel syngas production”, “Treatment of syngas”, “Underground coal gasification”, “Other methods of syngas production”.

Breakdown of documents by technology elements. Applications, 2017-2021 (by the number of mentions in patent documents)

| Technology element | Average rating | Share, % | Most active applicants |

|---|---|---|---|

| Feedstock preparation | 8.3 | 7.4 | Chevron USA, Inc., Commonwealth Scientific and Industrial Research Organization (Australia), IFP Energies nouvelles (France) |

| Syngas production in general | 8.7 | 30.4 | Mitsubishi Hitachi Power Systems Ltd. (Japan), Science & Technology Development Co Ltd. (China) |

| Primary technologies of syngas production | 10.1 | 33.0 | Haldor Topsoe A/S (Denmark), Air Liquid (France) |

| Microchannel syngas production | 9.2 | 2.3 | Greyrock Energy Inc. (The US), BP PLC (The United Kingdom) |

| Treatment of syngas | 9.0 | 12.5 | Air Liquid (France), ExxonMobil Upstream Research Company (The US), Haldor Topsoe A/S (Denmark) |

| Underground coal gasification | 7.1 | 4.0 | Xinjiang Guoliheng Clean Energy Technology Co. Ltd., Zhongwei (Shanghai) Energy Technology Co. Ltd. (China) |

| Other methods of syngas production | 8.5 | 10.5 | Air Products and Chemicals, Inc. (The US), Proton Tech Canada Inc., Ineos Bio SA (Switzerland) |

In total, 2921 individual IPC subgroups were assigned 65049 times in the patents of the patent database under consideration. Among IPC subgroups the most popular were C01B3/38 (Synthesis gas from hydrocarbons, using catalysts), C10J3/46 (Gasification of granular or pulverulent fuels in suspension), and C10J3/72 (Synthesis gas from hydrocarbons, other features). Among patents and patent applications the popularity of IPC subgroups C01B3/38 and C10J3/72 has grown considerably.

The number of applications to total number of documents by year were 0.61-0.52 in 2017-2021. At the same time, the number of start applications to total number of applications by year was on a high level (0.46-0.29).

In the years to come a growth should be expected in the number of granted patents related to “Feedstock preparation”, “Primary technologies of syngas production”, “Treatment of syngas”, “Saving ecosystems”, “High CAPEX / Equipment”, “High OPEX / Repair and replacement”. Less noticeable growth opportunities are seen in patents related to “Other methods of syngas production”, “Microchannel syngas production”, “Low efficiency of main processes”.

A complete version of the database “Synthesis gas” can be found at www.aenert.com