Structural batteries are energy storage systems with the additional feature of being able to bear weight. They are often employed in applications used for transport, such as electric vehicles or drones. There are two types of structural batteries: embedded batteries and laminated structural electrodes. One of the greatest challengesof this type of battery is that so far science has failed to produce structures which have good electrical as well as mechanical properties.

Now (2021), a structural battery with a much better performance than all previous models has been designed by scientists from Chalmers University, Sweden, which contains carbon fibres that can be used as an electrode, conductor, and load-bearing material at the same time. It also exhibits much better coefficients of electrical energy storage, stiffness and strength.

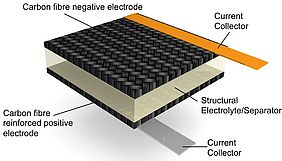

The battery has an energy density of 24 Wh/kg and a stiffness of 25 GPa. Its negative electrode is made of carbon fibre, and the positive electrode of a lithium iron phosphate-coated aluminium foil. The two layers are separated by a fiberglass fabric located in an electrolyte matrix. Previous research had shown that these materials might be capable of increasing performance, but the scientists also chose them to study their nature in general and the required separator thickness. These insights will be crucial if the performance of the battery is to be increased further, as is the aim of a follow-up project financed by the Swedish National Space Agency. This project is aimed at enhancingbattery life by replacing the aluminium foil with carbon fibre as load-bearing material in the positive electrode and making the fibreglass separator much thinner to decrease charging cycles. The project will be completed within two years.

For many years scientists have tried to improve the design of structural batteries. In 2017, for example, a design for a multifunctional structural battery comprising lithium-ion battery materials as load-bearing elements in a sandwich panel construction was developed. The structural battery prototype showed an initial capacity of 17.85 Ah, an energy density of 248 Wh L−1, a specific energy of 102 Wh kg−1, and a capacity retention of 85.8% after 190 charge–discharge cycles at ~C/3 rate and eight mechanical loading cycles. The mechanical stiffness in three-point bend tests proved that the battery materials were part of the load-carrying function of the sandwich panel. The study showed the promising potential of the structural battery for the efficient use of in electric vehicles.

In 2019, scientists designed a model for multifunctional performance of structural batteries. They matched the mechanical behaviour and electrical energy storage of the structural battery to the mechanical behaviour of a conventional carbon fibre composite and the electrical energy storage of a standard lithium-ion battery. In order to analyse the benefit of using structural batteries, the mass of the structural battery was compared to that of the two monofunctional systems if the battery design was improved. They found that the battery was able to outperform the commonly-used composite laminates and lithium-ion batteries.

There are many advantages to this new design: first and foremost, it produces a lighter structural battery cell as a result of reducing the amount of separator material and structural battery electrolyte. This leads to an increase in the energy density. Also, the improvement in electrochemical performance was able to enhance the mechanical performance as the elastic modulus was increased by almost 40% and 360% in the x‐ and y‐directions. The scientists found that both the electrochemical and mechanical performance was greatly increased by exchanging the Whatman GF/A separator with a significantly thinner and stiffer GF plain weave fabric.

This next generation structural battery shows great potential not only for the automotive industry, but also for consumer applications. It might be possible that in a few years smartphones, laptops or electric bicycles will be produced weighing half as much as today and being much more compact.