Every year, tons of carbon dioxide are emitted into the atmosphere. These large amounts of greenhouse gas have the potential to warm the temperature of the earth by 1.5°C until 2040. If the serious consequences of climate change are to be avoided, these emissions need to be reduced. In the fight against global warming, negative emissions technologies (NETs) to remove and sequester carbon dioxide from the atmosphere might play an important role.

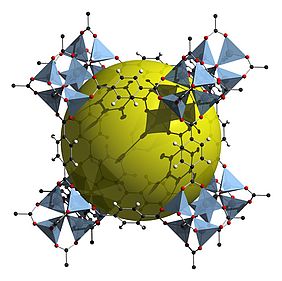

Now (2021), scientists at Berkeley Laboratory are researching a promising technology that might prove a decisive factor in reaching zero emissions. It comprises carbon capture using a material called a MOF, or metal-organic framework. This is a type of solid material that is highly porous and behaves like a sponge, able to absorb large amounts of a specific gas molecule, such as carbon dioxide. MOFs have been known for about 20 years, but only in the last decade has there been an explosion in research. They have extremely high internal surface areas, so, if designed properly, a small amount of MOF can remove an enormous amount of CO2 from the exhaust gas produced by fossil-fuel combustion. The scientists studied a new class of diamine-appended frameworks that showed high CO2 separation capacities in the presence of water, with minimal energy requirements arising from an unprecedented cooperative adsorption mechanism. They optimized them for efficient removal of CO2 from a power plant flue before the gas could enter the atmosphere and applied the MOF in a unique rotating bed system. Their strategy achieved quick capture-release cycle times as well as less energy consumption, which gives this technology a big advantage over conventional ways to capture CO2. It also reduces the need to divert high-value, high-temperature steam away from power production, thus avoiding a large increase in the cost of electricity. Moreover, the study highlighted that variations of the MOFs could be efficient for the removal of CO2 from other gas mixtures, including biogas, natural gas, and even directly from air.

Searching for MOFs suitable for CO2 capture has been at the centre of scientific research for several years. In 2016, scientists showed that a crystal engineering approach to tuning of pore-size in a coordination network, [Cu(quinoline-5-carboxyate)2]n (Qc-5-Cu), enabled ultra-high selectivity for CO2 over N2 (SCN ≈40 000) and CH4 (SCM ≈3300). Qc-5-Cu-sql-β, which is a narrow pore polymorph of the square lattice (sql) coordination network Qc-5-Cu-sql-α, adsorbed CO2 while excluding both CH4 and N2. Experimental measurements and molecular modelling were used to validate and explain the performance. Qc-5-Cu-sql-β was stable to moisture and its separation performance was not affected by humidity.

In 2017, a Cu(II) metal-organic framework (FJI-H14) with a high density of active sites was designed and synthesised, which displayed unusual acid and base stability and high volumetric uptake (171 cm3 cm−3) of CO2 under ambient conditions (298 K, 1 atm), making it a potential adsorbing agent for post-combustion CO2. Moreover, CO2 from simulated post-combustion flue gas could be easily converted into corresponding cyclic carbonates by the FJI-H14 catalyst. The scientists believed that the high CO2 adsorption capacity and moderate catalytic activity was the result of the synergistic effect of multiple active sites.

Test applications of MOFs have shown that the greatest advantage of using them in a unique rotating bed system is that they can achieve quick capture-release cycle times and reduced energy consumption. One of the research goals is to design materials that have a high capacity, a high capture rate, fast kinetics for CO2 adsorption, and a low regeneration temperature, whilst also reducing the co-adsorption of water so that no energy is wasted on its desorption. The main problem with conventional direct air capture is the cost, which is very high, ranging from $500 to $1,000 per ton. The reason for this is the amount of energy required for regenerating the adsorbent for releasing the CO2 in pure form so the material can then be re-used to capture more CO2. The scientists believe that the cooperative adsorption mechanism accessible in MOFs could significantly reduce the heat and vacuum requirements for regeneration. Another consideration in favour of MOFs is the reduced energy required for blowing air. With an increased capture rate of 90%, as seems possible with these “sponges”, you could lower the CO2 concentration to 40 parts per million, which means that processes require less air for removing the CO2, and can therefore save energy.

There is still a long way to go before this technology can be fully commercialised, ascertaining the mechanisms of how to manipulate things like delta-S (entropy) for CO2 adsorption still have to be understood properly so that less heat is required for CO2 release. In the long run, it is envisioned that widespread commercial deployment of such technology could result in a dramatic reduction in the cost and energy associated with carbon capture.

Energy News Monitoring

Sponge to Reduce Carbon Dioxide in the Air