In our modern world, tremendous amounts of organic waste, such as agricultural residues, food waste and animal manure, are produced every day. The greater part of this waste is transported to composting plants and incinerated to gain heat and electricity. This process often releases significant amounts of CO2 into the atmosphere. Waste, however, could be used to produce energy in a more sustainable manner, including various fuel sources such as biogas, biomethane, and also hydrogen. Depending on the production method used, hydrogen is an environmentally-friendly gas, which releases only water when combusted. Unfortunately, hydrogen is still largely generated from natural gas. Therefore, scientists have come up with various alternative methods enable hydrogen production from more sustainable sources, including e.g. organic waste which would not only make a contribution to mitigating the effects of global warming but also help reduce the amount of waste people produce.

Now (2022), scientists at Fraunhofer IPA together with the metal industry have researched the potential of converting plant residue to sustainable hydrogen. For this purpose, they first analysed different processes for converting biomass into hydrogen in order to make out those which were technically mature and could work efficiently. They were also trying to find means to capture the greenhouse gas produced by the plants during incineration with the aim of either using it as raw material in the chemical industry or storing it underground in abandoned natural gas fields.

The scientists took waste from local fruit farmers and vintners, as well as cardboard, wood and canteen and turned it into hydrogen. This hydrogen was then directly used in metal processing. The production processes were adapted to the feedstock that were being used: leftover fruit and waste was fermented with the help of bacteria in dark container until hydrogen and CO2 was received. Wood and paper, however, were difficult to ferment in this manner. There it was more efficient to use a wood gasifier. Part of the research goal was to develop technical optimisation approaches to reduce costs and ensure that the processes used would be environmentally-friendly.

The study also found that purple bacteria were especially good at producing hydrogen from fruit and dairy waste. Researchers at the University of Stuttgart, who joined the project, were able to modify the bacterium so that it needed less light and thus also less energy. The two teams of scientists are now researching methods to produce hydrogen with the help of purple bacteria on a large scale. The team at Fraunhofer IPA is also collaborating with the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB to investigate how microbes could disintegrate wood waste for hydrogen and chemicals production.

Moreover, in the course of the study possible locations of hydrogen hubs in Germany, especially in Baden-Württemberg were identified. Using computer simulations, researchers at Fraunhofer IPA demonstrated that under specific circumstances within ten years 30 percent of fossil energy could be replaced by regionally produced green hydrogen.

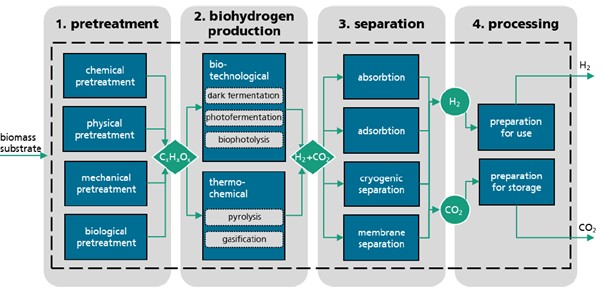

For many years, scientists have tried to harness the energy potential of hydrogen. In 2021, scientists designed a new concept for the production of hydrogen with net negative emissions. The concept combined biohydrogen production by means of biotechnological or thermochemical processes with carbon dioxide (CO2) capture and storage. The benefits of the new system included the high concentration and purity of the CO2 as well as the emission-free use of hydrogen which led to a higher possible CO2 capture rate compared to hydrocarbon-based biofuels generated with Bioenergy with Carbon Capture and Storage (BECCS) technologies. Also, the role of carbon-negative hydrogen in future energy systems was analysed. For this purpose, the ecological impacts were estimated and an economic assessment was made. For the production and use of carbon-negative hydrogen, it was calculated that in Germany 8.49–17.06 MtCO2,eq/a could be saved until 2030. The production costs for carbon-negative hydrogen would have to be below 4.30 € per kg in a worst-case scenario and below 10.44 € in a best-case scenario so as to be competitive in this country.

Image: Process diagram for carbon-negative hydrogen production using the Hydrogen Bioenergy with Carbon Capture and Storage (HyBECCS) approach.

Source: Johannes Full, Steffen Merseburg, Robert Miehe and Alexander Sauer/ A New Perspective for Climate Change Mitigation—Introducing Carbon-Negative Hydrogen Production from Biomass with Carbon Capture and Storage (HyBECCS)/ Sustainability 2021, 13, 4026, 5 April 2021/ doi.org/10.3390/su13074026/ Open Source This article is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0)

In 2022, scientists studied the plastic wastes polypropylene (PP) and polyethylene (PE) to research how efficiently they could be converted into hydrogen. Two cases were modelled to produce hydrogen using Aspen Plus®, a chemical process simulator. Case 1 contained three main processes (plastic gasification, syngas conversion, and acid gas removal). Case 2 combined plastic gasification with steam methane reforming (SMR) to enhance the overall hydrogen production. The two cases were then analysed in terms of syngas heating values, hydrogen production rates, energy efficiency, greenhouse gas emissions, and process economics. The results showed that Case 2 generated 5.6% more hydrogen than Case 1. The overall process efficiency was increased by 4.13%. Case 2 reduced the CO2 specific emissions by 4.0% and decreased the hydrogen production cost by 29%.

Image: Hydrogen production from waste plastics: PE and PP (case 1)

Source: Ali A. Al-Qadri, Usama Ahmed, Abdul Gani Abdul Jameel, Umer Zahid/ Simulation and Modelling of Hydrogen Production from Waste Plastics: Technoeconomic Analysis/ Polymers 14(10):2056, May 2022/ DOI:10.3390/polym14102056/ Open Source This article is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0)

There are several benefits involved in using hydrogen as fuel source: green hydrogen has the potential to accommodate the energy demands of selected industrial sectors and heavy goods traffic regionally. The researchers found that decentralised hydrogen production and use are economical if the distribution centres (i.e., hubs) are located strategically. With the help of green electricity, electrolysers could be operated there, which can split water into hydrogen and oxygen. To avoid transport costs, the hubs should be near its prospected consumers. Another important criterion for choosing a location is the need of local industries for process heat, high-temperature processes and hydrogen gas, as used in the production of nitrogen fertiliser. Moreover, locations would be ideal which are situated near busy roads with truck depots where hydrogen filling stations can be implemented.

Hydrogen is a gas which is colourless and odourless. Hydrogen is non-toxic and not causing environmental damage which makes it environmentally neutral. Considering the remarkable achievements which have been made in hydrogen fuel research, there is hope that we will soon have a sustainable and efficient alternative means to power society.