For quite some time global climate change, linked to the accumulation of greenhouse gases, has caused concerns regarding the use of fossil fuels as the major energy source. To mitigate climate change while ensuring sufficient energy supply, one solution is to rely on the ability of microorganisms to use renewable resources for biofuel synthesis using either plants or the waste that they produce.

Now (2020), researchers at the Lawrence Berkeley National Laboratory (Berkeley Lab) have succeeded in modifying a microbe to efficiently generate a compound of interest with the help of a computational model and CRISPR-based gene editing. The process employs computer algorithms using real-world experimental data to identify what genes in a host microbe could be inactivated to use the energy of the organism for producing high quantities of a target compound. Currently, many scientists in this field still rely on trial-and-error experiments to find out what gene modifications might lead to improvements. Additionally, most microbes used for biomanufacturing processes that generate non-native compounds with alien genes having been inserted into the host genome can only produce large quantities of the target compound after the microbe has reached a certain growth phase, which causes slow processes that waste energy. The new metabolic rewiring process enables the entire metabolism of the microbe to generate the compound at all times. To test product/substrate pairing, the team conducted experiments with a soil microbe called Pseudomonas putida that had been engineered to carry the genes to make indigoidine, a blue pigment. The scientists looked at 63 potential rewiring strategies and, using a workflow that evaluated possible combinations of desirable host characteristics, determined that only one of these was experimentally realistic. Then, they performed CRISPR interference (CRISPRi) to block the expression of 14 genes on the basis of their computational predictions.

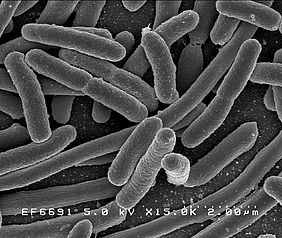

Research to modify bacteria with the aim of producing biofuels has been carried out for many years. In 2013, for example, scientists at the University of California, Los Angeles (UCLA), found a method for producing cheaper and cleaner biofuels by using genetic engineering to fundamentally change how certain organisms process sugar. The UCLA researchers combined genes from a variety of organisms, designing an alternative way to process sugar that did not emit carbon dioxide where all of the carbon in sugar was used to make biofuel. They created genetically modified E. coli bacteria to demonstrate the process. With the help of hydrogen, made by splitting water with solar power, they were able to eliminate all of the carbon dioxide emitted during fermentation. However, the cost was too high for the process to be economical. The new approach produced more ethanol from sugar, which would require less land corn or other biomass production. The scientists estimated that the biggest cost savings would be for cellulosic ethanol derived from biomass.

In 2019, scientists proposed a high-pressure fermentation strategy in combination with in situ extraction using the abundant and renewable solvent supercritical carbon dioxide (scCO2). To this end, they domesticated and bred a scCO2-tolerant strain of Bacillus megaterium, previously isolated from the formation waters of a CO2 field, to create branched alcohols that would have potential use as biofuels. After establishing induced-expression under scCO2, isobutanol production from 2-ketoisovalerate had a greater than 40% yield with co-produced isopentanol. They also presented a process model to compare the energy required for the process to other in situ extraction methods and found that the scCO2 extraction was potentially competitive.

The advantages of the new technology are the following: with product/substrate pairing, the time needed to develop a commercial-scale biomanufacturing process with this method could be reduced significantly. Owing to computational modeling and advanced genetics, as well as in collaboration with other institutions, such as the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), the scientists were able to demonstrate that the technology could be employed even at higher production scales.

This new approach to fuel production might completely reshape the renewable fuel landscape. It could dramatically speed up the research and development phase for new biomanufacturing processes as well as enable commercialisation of cutting-edge bio-based products, such as sustainable fuels and plastic alternatives.