Aenert. Research Laboratory news

Hydrogen is a clean fuel. It can be produced from a variety of resources, such as natural gas, nuclear power, biomass, and renewable power like solar and wind which is why it is a convenient fuel option for transportation and electricity generation applications. These include cars, houses, portable power, and many more applications. Hydrogen is also an energy carrier that can be used to store, move, and deliver energy produced from other sources.

Hydrogen fuel can be produced through several methods. Among the most common methods today are natural gas reforming (a thermal process), and electrolysis. There are other methods as well, including solar-driven and biological processes. Thermal processes for hydrogen production, for example, typically employ steam reforming, where steam reacts with a hydrocarbon fuel to produce hydrogen. Hydrocarbon fuels which can be reformed to produce hydrogen include natural gas, diesel, renewable liquid fuels, gasified coal, or gasified biomass. Another method is electrolysis, where hydrogen is created from water molecules. Solar-driven processes, on the other hand, use light as the agent for hydrogen production. They comprise photobiological, photoelectrochemical, and solar thermochemical reactions. Finally, biological processes can employ microbes such as bacteria and microalgae to produce hydrogen through biological reactions. To make hydrogen greener, recently several projects have been launched to test sustainable methods of its production.

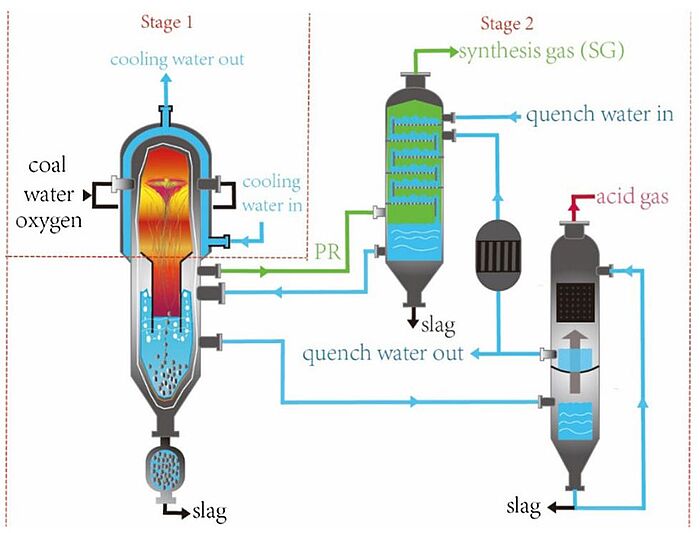

In 2021, a project was launched to enable gasification of coal-plastic-biomass for reducing CO2 emissions and syngas/H2 production. The aim of the project is to demonstrate a hydrophobic layer encapsulated biomass production that is suitable for a slurry with solid content with ≥60 wt% of blended coal/biomass/plastic fuel. Also, lab-scale kinetic and gasification studies on the blended coal/biomass/plastic fuel will be conducted. Tests will be performed in the commercially relevant, UK CAER 1 TPD entrained flow gasifier. The materials used will be torrefied wood mixed with either PET plastic or mixed plastic. For this purpose, pellets were pressed with 0.3 g sample in a 6.35 mm diameter die at 260oC with 1 ton of pressure for 1 minute.

Image: Schematic diagram of the entrained gasification process

Source: Kai Dong, Qianqian Rong, Mingheng Li, Juan Lin, Ruirui Xiao, Yifan Li/ A Novel Simulation for Gasification of Shenmu Coal in an Entrained Flow Gasifier/ Chemical Engineering Research and Design 160, June 2020/ DOI:10.1016/j.cherd.2020.06.015/ Open Source This is an Open Access article is distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0)

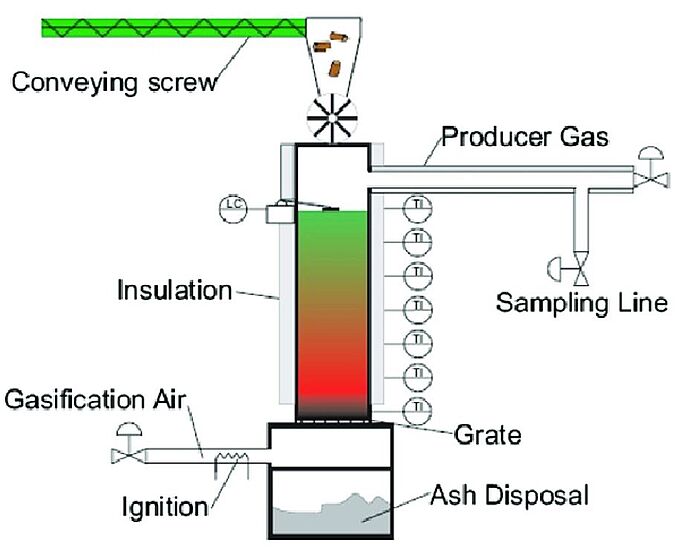

In May 2022, a project was launched to qualify coal, biomass, and plastic waste blends based on performance testing of selected pellet recipes in a pilot-scale updraft moving-bed gasifier. The testing is aimed at providing relevant data to advance the commercial-scale design of the moving-bed gasifier to be able to produce hydrogen. Especially the effects of the waste plastics on feedstock development and the resulting products are of particular interest the research team. The gasifier used is Hamilton Mauer International, Inc. (HMI)’s moving-bed gasifier which also works well with wood chips. However, mixtures of these fuels with plastic wastes have not yet been prepared and gasified together. The feedstocks will be prepared by California Pellet Mill (CPM). The technical tasks and current status for this two-year research project include feed preparation, such as PRB coal, corn stover biomass, and car fluff waste plastics, test plan development, gasifier testing, which will provide information on the reaction efficiency and provide relevant data to improve the gasifier design, as well as data analysis and reporting. The gained results will be used to specify what feedstock blends can be successfully gasified as well as quantify gasifier outputs with regard to the respective blends. Initial gasification tests have been conducted, and all the lab scale tri-fuel pellet gasification runs were completed by the autumn of 2022. Performance data will enable modeling of a full-scale HMI industrial scale gasifier supporting both CHP and hydrogen production.

Image: Sketch of the moving-bed counter-current gasifier

Source: Andreas Schwabauer, Marco Mancini, Yunus Poyraz, Roman Weber/ On the Mathematical Modelling of a Moving-Bed Counter-Current Gasifier Fuelled with Wood-Pellets/ Energies 14(18):5840, September 2021/ DOI:10.3390/en14185840/ Open Source This is an Open Access article is distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0)

There are several advantages to using hydrogen as fuel: Hydrogen is a rich source of energy which is in bountiful in supply. Hydrogen can be produced either directly where it will be used or centrally and then distributed. Hydrogen gas can be harnessed from methane, gasoline, biomass, coal or water. Parameters such as amounts of pollution, technical challenges, and energy requirements vary depending on the sources used. When burnt, the byproducts are completely safe. Aeronautical companies actually use hydrogen as a source of drinking water. After utilisation, it is normally converted to drinking water for astronauts on ship or space stations.

Hydrogen is believed to be key to creating a long-term carbon-free future and can complement renewables like wind or solar, which generate power only intermittently. Hydrogen is an important technology and will allow utilities to adopt much greater levels of renewables.

By the Editorial Board