In the last two decades directional drilling has been rapidly developing in various oil and gas producing countries, primarily in the United States. It has become particularly indispensable for shale gas and tight oil plays. According to U.S. Energy Information Administration (Today in Energy, June 6, 2019), in 2018 in the US the share of horizontal wells in the production of shale gas and tight oil comprised 96-97% against 14-15% in 2004. In most cases, directional drilling is used in combination with hydraulic fracturing, which is often perceived as a single, inseparable technology, however, directional drilling also has its own individual applications. Interesting patterns are demonstrated by the statistics of the use of horizontal drilling, depending on the well flow rate (The Distribution of U.S. Oil and Natural Gas Wells by Production Rate January 2022). Regardless of reservoir characteristics, horizontal drilling dominates for high-rate wells with a production rate bracket of more than 100 BOE/d. Here, in 2020, the share of horizontal wells was almost 87.5%, while for marginal wells (less than 10 BOE/d) it was only 3.3%. In 2010, these figures were 40.6% versus 0.95%, respectively. Thus, we can see a substantial increase in the use of directional drilling in recent years in general, and a significant impact of this technology on well productivity.

However, directional drilling is technically complex and rather expensive technology. Implementation of directional drilling requires extensive use of various drilling sensors and special tools, for instance, whipstocks, bottomhole, drill bits, turbodrill turbines, and drilling motors. It is important to maintain the downhole tubular bend radius and diameter (usually at least 100 feet of radius per 1 inch of tubular diameter) or diameter to wall thickness (D/T) ratio. Contemporary directional drilling technologies in their configuration include rotary steerable systems and sophisticated software that allows for precise well placement and automation of drilling processes.

According to "Trends in U.S. Oil and Natural Gas Upstream Costs/ U.S. Energy Information Administration/March 2016", percentage breakdown of cost shares for U.S. onshore oil and natural gas drilling and completion includes 15% rig and drilling fluid and 11% casing and cement. Drilling costs include drilling rig rental, tubulars such as well casing and liner, drilling fluids, diesel fuel, and cement. The total cost of a well can vary greatly from play to play and within one play, depending on such factors as depth and well design. The average cost of drilling a horizontal well ranges from 1.8 to 2.6 million US dollars and comprises from 27% to 38% of the total well cost. This study also mentions that "…Directional drilling cost parameters are set at the following levels - for Drilling Cost per Total Depth - $100-150 per foot and for Completion Cost per Lateral Foot - an average of about $500 per foot".

An important role in the total operating costs for directional drilling is played by items related to the repair and replacement of equipment (HORR or High OPEX / Repair and replacement). Below is a brief analysis of inventions, which consider technical proposals that to one degree or another contribute to solving this problem. More than 9000 patent documents over the past twenty years were selected for the patent analysis using the Advanced Energy Technologies methodology. Patents and patent applications have been published in 48 patent offices around the world by 1362 Applicants from 38 countries.

The issue related to the repair and replacement of equipment is one of the most popular in the general pool of inventions related to directional drilling. This is also substantiated by the high level of patenting activity among inventors, especially in the last five or six years.

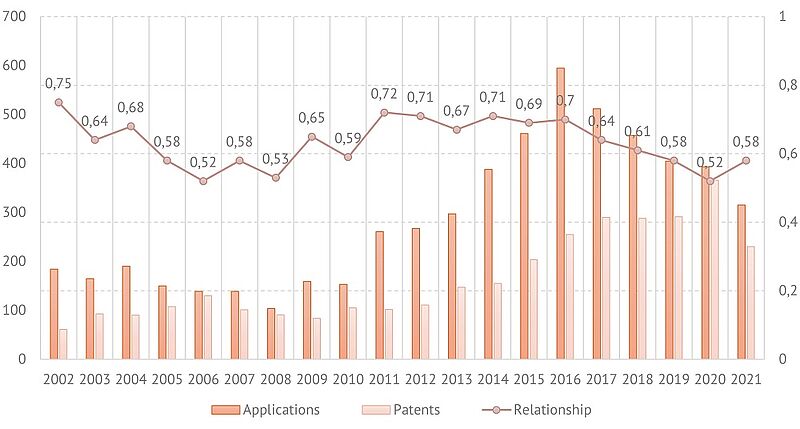

Directional drilling. Repair and replacement of equipment. Relationship of number of applications to total number of documents by year

As it appears from the chart, the general pool of patented solutions has recently been fuelled by a significant number of new patent applications each year. Among them, for example, in 2020, about a half were start patent applications that were not part of previously formed patent families. Also, this subject is characterized by the annual appearance of new Applicants, new IPC subgroups, as well as new patent offices where patent applications are registered. This indicates the importance of this issue and the common desire of developers and operators to resolve it. At the same time, judging by the growth in the volume of patenting, the creative potential of inventors is far from being exhausted.

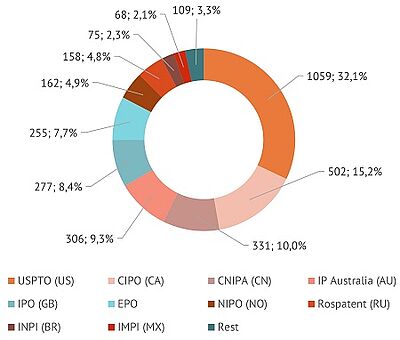

Over a twenty-year period, the largest number of patents - 32.1% - was issued by the USPTO (US). More than 5% of the total number of patents were issued by each of the top five patent offices that include CIPO (CA), CNIPA (CN), IP Australia, IPO (GB), and EPO. In the past five years, the CNIPA Patent Office (CN) has become the leader by the number of registered patent applications.

Directional drilling. Repair and replacement of equipment. Breakdown of inventions by patent offices. Patents, 2002-2021 (left); Applications, 2017-2021 (right)

However, in both statistical options presented above, the leadership among the Applicants remained with the US residents. In the case of patents, their share was more than 71%, and for patent applications in the last five years – more than 53.5%. In addition to them, high activity was shown by the residents of Canada, China, Great Britain, the Netherlands, Japan and Saudi Arabia.

The list of top 10 leading Applicants for the case of patents is as follows:

Directional drilling. Repair and replacement of equipment. Top applicants. Patents, 2002-2021

| Status | Country | Name | Average rating | Total 2002-2021 |

|---|---|---|---|---|

| Company | US | Halliburton Energy Services, Inc. | 17.9 | 1147 |

| Company | US | Baker Hughes Incorporated | 17.8 | 207 |

| Company | US | Weatherford/Lamb Inc | 18.6 | 137 |

| Company | US | Schlumberger Technology Corporation | 18.1 | 136 |

| Company | US | Smith International, Inc. | 16.5 | 91 |

| Company | NL | Schlumberger Technology B.V. | 16.6 | 72 |

| Company | JP | JFE Steel Corporation | 12.6 | 53 |

| Company | US | ExxonMobil Upstream Research Company | 17.5 | 49 |

| Company | NL | Shell Internationale Research Maatschappij B.V. | 16.6 | 48 |

| Company | SA | Saudi Arabian Oil Company | 18 | 43 |

The share of patenting leader – Halliburton Energy Services, Inc. – in total Market involvement ratio was almost 35% (Market involvement ratio = volume ratio multiplied by ownership ratio, where Volume ratio - share of applicant documents in total number of documents, Ownership ratio - applicant's participation share in total number of documents). Following the leader, Baker Hughes Incorporated had a little more than 6% on this indicator. Halliburton Energy Services Inc. retained its leading position in the last five years in terms of the number of registered patent applications.

Directional drilling. Repair and replacement of equipment. Top applicants. Applications, 2017-2021

| Status | Country | Name | Average rating | Total 2017-2021 |

|---|---|---|---|---|

| Company | US | Halliburton Energy Services, Inc. | 12.6 | 419 |

| Company | SA | Saudi Arabian Oil Company | 13.3 | 67 |

| Company | JP | JFE Steel Corporation | 8 | 38 |

| Company | US | Baker Hughes a Ge Company, LLC | 10.3 | 36 |

| Company | US | Baker Hughes Incorporated | 12.4 | 28 |

| Company | US | Chevron USA, Inc. | 12.5 | 27 |

| Company | US | Landmark Graphics Corporation | 11.7 | 17 |

| Company | US | National Oilwell Varco LP | 11.2 | 16 |

| Company | US | Weatherford Technology Holdings LLC | 12.3 | 16 |

| Company | CA | Evolution Engineering Inc. | 11.8 | 16 |

In the considered group of patent documents, along with HORR problems, the most frequently mentioned were also High OPEX / Operation and consumables, Low efficiency / Main processes, and High CAPEX / Equipment production. Among the types of technical solutions, inventors generally chose devices and methods, while compositions were encountered less often. In the pool of patents and applications, among all designated IPC subgroups, the most common were E21B 7/06 (Deflecting the direction of boreholes), E21B 7/04 (Directional drilling), E21B 17/10 (Wear protectors; Centralising devices), E21B 41/00 (Equipment or details not covered by groups E21B 15/00-E21B 40/00), E21B 44/00 (Automatic control systems specially adapted for drilling operations, i.e. self-operating systems which function to carry out or modify a drilling operation without intervention of a human operator, e.g. computer-controlled drilling systems; Systems specially adapted for monitoring a plurality of drilling variables or conditions).

Among the patent documents selected for this analysis, the largest patent family containing documents related to the HORR problem includes 104 inventions and is represented by the core document US9010411B1 (Core document is a base document for which a complete description of the invention is available in generally-accessible patent databases):

Downhole tool and method of use / P: US9010411B1 / IPC: E21B23/06 / VanLue Duke / National Boss Hog Energy Services LLC (US) / Appl. date: 17/11/2014; Publ. date: 21/04/2015. Technologies: DD, HF / Technology elements: DR / Problems: HCEP, HORR, HOOC / Invention types: D / Rating: 16 / Claims: 19

The following are examples of patents with the highest rating calculated in accordance with the Advanced Energy Technologies methodology in the group of patent documents related to the HORR problem:

Directional drilling, High OPEX / Repair and replacement. Prominent patent documents by rating, 2002-2021:

Apparatus and method for gravel packing an interval of a wellbore / P: US6557634B2/ IPC: E21B43/02, E21B43/04, E21B43/04 / Hailey Jr Travis T, Henderson William David, Crow Stephen Lee, Nguyen Philip D / Halliburton Energy Services, Inc. / Appl. date: 06/03/2001; Publ. date: 06/05/2003, Technology categories: DD / Technology elements: DR / Problems: HOOC, HORR, LEMP / Technical solution types: D, M / Claims: 106 / Rate: 23

Circulation system facilitating gravel slurry removal / P: NO341266B1/ IPC: E21B21/10, E21B34/14, E21B43/04 / Richards William Mark, Penno Andrew / Halliburton Energy Services, Inc / Appl. date: 30/03/2017; Publ. date: 25/09/2017. Technology categories: DD / Technology elements: DR / Problems: HOOC, HORR, LEMP / Technical solution types: D, M / Claims: 36 / Rate: 22

井 下可有线调节的流量控制装置及使用该装置的方法 (Wireline-adjustable downhole flow control devices and methods for using same) / P: CN102667053B/ IPC: E21B21/08, E21B21/10, E21B34/14, E21B43/12 / O'MALLEY EDWARD J, PETERSON ELMER R, CORONADO MARTIN P, GARCIA LUIS A / BAKER HUGHES INC / Appl. date: 15/12/2010; Publ. date: 03/12/2014. Technology categories: DD / Technology elements: DR / Problems: HOOC, HORR / Technical solution types: D, M / Claims: 20 / Rate: 22

Annular isolators for expandable tubulars in wellbores / P: US7404437B2/ IPC: E21B33/12 / Brezinski Michael M, Chitwood Gregory B, Echols Ralph H, Funkhouser Gary P, Gano John C, Herman Paul I, Kilgore Marion D, Powell Ronald J, Ray Thomas W, Steele David J, Taylor Robert S, Todd Bradley L, Tuckness Cynthia / Halliburton Energy Services, Inc. / Appl. date: 03/08/2007; Publ. date: 29/07/2008. Technology categories: DD / Technology elements: DR / Problems: HORR, LEMP / Technical solution types: D, M / Claims: 14 / Rate: 22

SEALED BRANCH WELLBORE TRANSITION JOINT / P: CA2491807C/ IPC: E21B17/08, E21B7/08, E21B33/10 / HEPBURN NEIL, BERGE FRODE, DEMONG KARL / HALLIBURTON ENERGY SERVICES, INC. / Appl. date: 19/04/2007; Publ. date: 25/01/2011. Technology categories: DD / Technology elements: DR / Problems: HOOC, HORR / Technical solution types: D, M / Claims: 40 / Rate: 22

The following is a brief list of examples of patented solutions that describe inventions directly related to drilling and aimed at solving the problem of high operating costs associated with the repair and replacement of equipment:

- US20180274299A1 – the problem of component wear is solved by providing separate fluid flows used to drive the motor and the drill hammer;

- US11261667B2 – the problem of a high level of loads and vibrations in the elements of the drilling rig is solved by using a drilling assembly of a special design, equipped with a stabilizer and a dampener;

- US10934781B2 – the reliability of the drilling direction control mechanisms is ensured by a hydraulic arrangement with a plurality of actuators, valves and directors, the interaction of which is controlled by a system of sensors that read the parameters of the rotation of the drill string.

Patent application US20180274299A1 registered by Strada Design Limited (GB) discloses a drilling system configured to be used with two flows of fluid. The drill string of the system includes two channels, one of which is formed in an annular shape, and the second is located inside the first one. This allows the two fluids to pass separately and independently through the drill string. The first fluid drives a drill hammer, and the second fluid flows through the motor, which in turn rotates the drill hammer. The first fluid exits the drilling system near the hammer bit. The second fluid flows into the well drilled by the drilling system through the bit face of the hammer bit or through the down hole in the shroud located over the hammer. The second fluid can be selectively directed to the wellbore before or after the transfer of energy to the motor. The system also includes a steering mechanism and a control mechanism that is located between the motor and the hammer, or integrated into the motor. Among the drawbacks of existing systems, the authors mention the rapid wear of the drill hammer surfaces by the drilling fluid that drives it, resulting in the need for frequent replacement of the hammer.

The patent family of the document includes 25 documents published in RU, US, AU, CA, WO, BR, CL, CO, CR, CU, DO, EP, JP, MX, PE, SV, CN, ZA, EC between 2016 and 2020.

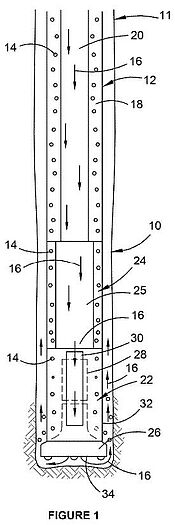

Image from US20180274299A1

A device for drilling curved and straight sections of a wellbore is proposed in patent US11261667B2 published by Baker Hughes Incorporated (US). The device includes a drilling assembly connected to a drill pipe and containing a drill bit rotated by a drive through a shaft. It also includes a housing consisting of an upper section and a lower section, in which a bearing is positioned to provide rotational connection with the shaft. The device contains a pivot member, which is equipped with a stabilizer and is made in the form of a pin or a ball joint between the upper and lower sections. Around the pivot member, the lower section tilts in a selected plane relative to the upper section when the drill pipe is not rotating. This allows a curved section of the well to be drilled. The axis of rotation of the pivot member is located outside the longitudinal axis of the drilling assembly for tilt initiation when an axial load is applied to the drilling assembly. For drilling straight sections of the well, the drill pipe is rotated, which reduces the tilt between the upper and lower sections. The drilling assembly also includes an end stop to limit the tilt angle to the required one, a force application device to initiate the tilt (spring or hydraulic device), a dampener to reduce the rate of the tilt and dampen variation of the tilt when the drill pipe is stationary.

The claims also describe additional arrangements for the device and methods of using it. The invention is aimed at reducing loads and vibrations in the elements of the drilling assembly. The patent is a part of a family comprising 29 documents published in US, CA, WO, BR, EP, RU, CN between 2016 and 2022.

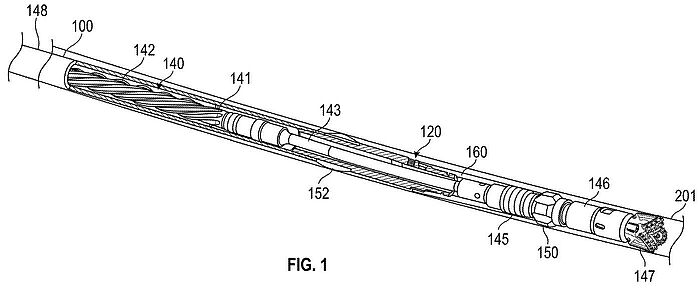

Image from US11261667B2

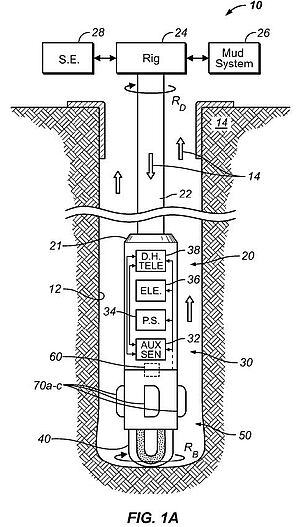

Patent US10934781B2 registered by Weatherford Technology Holdings LLC (US) proposes a drilling assembly for deviating a borehole.

According to the text of the document, a housing is disposed on the drill string, equipped with a plurality of directors, which can be in a retracted condition and an extended condition. The directors change their position by the means of a system of valve members and actuators that move the flow of fluid to or from the directors, thus increasing or decreasing the pressure in them. The actuators are individually controlled by a controller that is disposed to rotate with the housing, determines angular orientations of the directors relative to a desired trajectory for the borehole, and transmits the data to the actuators to adjust the borehole deviation. The controller includes a gyroscopic sensor that measures the angular rate of the housing during rotation; a magnetometer that measures the orientation of the housing during rotation relative to the borehole; an accelerometer that measures a gravity reference; and a control circuitry that, based on the sensor data and taking into account the desired trajectory of the borehole, transmits instructions to the actuators.

The patent claims also describe the technical features of the system and options for its implementation. The authors of the invention point out that there is necessity to ensure the reliability of the system for controlling the direction of drilling. The invention was published in EP, US, CA, WO between 2016 and 2021.

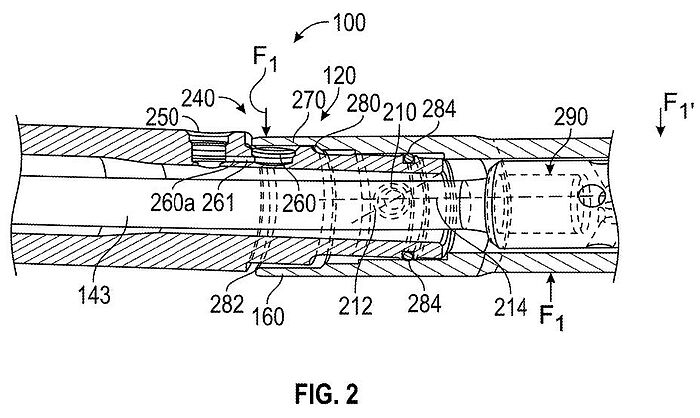

Image from US10934781B2

More detailed information about inventions in the field of directional drilling, and patent research methodology can be found on aenert.com and in DIRECTIONAL DRILLING. Patent Database. August 2022.