Hydrocarbons in low-permeable shale rocks, unlike oil and gas-rich natural reservoirs, are located on a much larger area and, lacking mobility, are clogged in relatively small cavities.

To ensure the extraction of hydrocarbons from such rocks, at least two additional measures are required: to increase the contact area of the well with the gas-containing formation and to increase the permeability of the rock. Since the thickness of shale gas-bearing formations is usually small and averages from 300 to 1000 ft, conventional vertical wells cannot provide sufficient productivity and are quickly depleted. Therefore, to implement the first of the tasks – to increase the area of contact between the well and the gas-containing formation – horizontal directional drilling technology was developed and successfully applied. With this configuration of the well, especially if there are several of them and if they are located inside the gas-bearing layer, satisfactory area of contact with the gas-containing formation is achieved.

Various drilling sensors, special tools, for example, whipstocks, bottomhole, drill bits, turbodrills, drilling mud motors, have been widely used to implement Directional Drilling. Maintaining the bending radius of the borehole pipe and its diameter (usually at least 100 ft radius per 1-inch of pipe diameter) or diameter-to-wall thickness ratio is important. Modern directional drilling technologies in their configuration contain rotary steerable systems and sophisticated software that allows for accurate placement of wells and automate drilling processes. Currently, directional drilling is widely used not only for the production of shale gas or oil, but to increase the production of traditional hydrocarbons.

However, directional wells present a number of drilling problems in addition to those encountered in vertical wells. These are related to factors such as the well profile and the reduced axial component of gravity acting along the borehole. As the angle of inclination increases, drilling problems become more severe. Also, the inability to consistently follow a prescribed well path and to hit the targets identified are counted among the more serious issues of directional drilling.

A substantial part of effective technical solutions aimed at the development of these technologies is concentrated in patent documents registered with various patent offices. EnerTechUp company performed a systematic search of patent documents on this subject, prepared a unique patent database, and conducted a thorough statistical analysis of the patenting activity results. All patent documents are labelled with specialized marking, allowing their grouping by semantic belonging, including sorting by patent offices, applicants, technological parameters, problems they are aiming to solve. These original features of the database create unique opportunities for users of all levels to timely monitor the latest engineering achievements in the field of oil and gas production from low permeability plays, and to predict the development directions in the oil and gas industry as a whole, or for individual regions and companies. Particularly, the data base allows lists of patent documents to be formed for the most popular technologies of directional drilling of underground formations, for instance, deflecting the direction of boreholes or correction of deflected boreholes, and for elements of equipment involved, such as special apparatus for deflecting the boring, waste utilization, etc.

The database includes almost 35 thousand patent documents published in generally-accessible sources all over the world during 1993 and 2022. General methodology of patent database compilation and statistical evaluation used in this product can be found at aenert.com.

The most active registration of patent applications took place in 2015-2019. The most popular patent offices with applicants were USPTO (the United States), CIPO (Canada), CNIPA (China), and IP Australia (AU). Representatives of 62 countries around the world participated in the patenting process. The largest number of patents were granted to the residents of the United States, China, Canada, and the Netherlands. The largest number of patent applications in the last five years were filed by the residents of the United States and China. The largest number of patents were issued to non-residents by USPTO (the United States), CIPO (Canada), CNIPA (China), and IP Australia. The list of top 10 most productive applicants by the number of patents includes:

Halliburton Energy Services, Inc. (US)

Baker Hughes Incorporated (US)

Schlumberger Technology Corporation (US)

Weatherford/Lamb Inc (US)

Schlumberger Technology B.V. (NL)

Landmark Graphics Corporation (US)

Shell Internationale Research Maatschappij B.V. (NL)

Shell Oil Company (US)

Schlumberger Holding Limited (VG)

In the majority of cases the authors indicated Low efficiency / Main processes and High OPEX / Repair and replacement as the problems the technical solutions disclosed in the patents and patent applications were aiming to solve. In the vast majority of cases, the inventions were related to devices or methods. Further this article provides several examples of recent patent documents related to drilling operations in the field of directional drilling with a focus on solving the problems of high costs of repair and replacement of the equipment. Specifically, below are provided several systems and methods involving smart solutions in drilling management procedures allowing automated control of drilling systems or facilitated communication of downhole tools with surface control units.

The largest patent documents in the field of technical solutions related to repair and replacement of directional drilling equipment are formed by the following applicants:

National Boss Hog Energy Services LLC (US) - US9010411B1* (AU CA CN EP MX US WO);

Swelltec Limited (GB) - US8752638B2* (BR CA EP GB NO US WO);

Saudi Arabian Oil Company (SA) - US10533393B2* (CA CN EP JP US WO);

Halliburton Energy Services, Inc. (US) - EA20877B1* (AU BR CA CN CO EA EP GB MX MY US WO);

Evolution Engineering Inc. (CA) - US9523246B2* (CA CN EA EP US WO);

Underground Solutions Technologies Group Inc (US) - US6982051B2* (AU BR CA CN CR EP HK JP MX SG US WO).

* Core document is a base document for which a complete description of the invention is available in generally-accessible patent databases

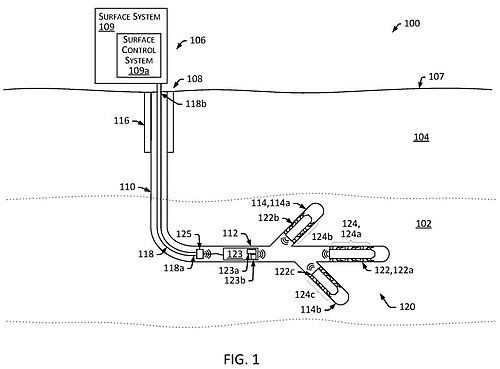

Thru-tubing retrievable intelligent completion system / P: US10570696B2 / IPC: E21B33/14, E21B34/06, E21B43/12, E21B41/00, E21B23/06, E21B17/10, E21B33/13, E21B44/00, E21B33/127, E21B47/12, E21B33/16, E21B17/00, E21B33/12, E21B47/01, E21B47/10, E21B47/06 / Arsalan Muhammad, Noui-Mehidi Mohamed N / Saudi Arabian Oil Company / Appl. date: 28/11/2017; Publ. date: 25/02/2020 / United States Patent and Trademark Office / Core document: US10533393B2, Claims: 21 / Rating: 20

The invention discloses a thru-tubing well completion system and method for wellbores, including those having horizontally-oriented portions, in oil and gas production applications. The system comprises a sub-surface completion unit (SCU), one or more SCU centralizers, one or more SCU anchoring seals having an un-deployed position and a deployed position. In the un-deployed position, the SCU passes through the tubing, while the deployed position provides sealing to ensure isolation between regions in the wellbore. SCU anchoring seals are detachable and can remain in the target zone when the body of the SCU is removed. Switching through the un-deployed and deployed positions is performed by changing the diameters of the downhole tools by inflating with a hardening substance. The system is controlled by a surface control system configured to directly and wirelessly communicate with a SCU wireless transceiver unit. The invention is aimed at reducing the costs associated with workover operations and related revenue losses.

completion system and method for wellbores, including those having horizontally-oriented portions, in oil and gas production applications. The system comprises a sub-surface completion unit (SCU), one or more SCU centralizers, one or more SCU anchoring seals having an un-deployed position and a deployed position. In the un-deployed position, the SCU passes through the tubing, while the deployed position provides sealing to ensure isolation between regions in the wellbore. SCU anchoring seals are detachable and can remain in the target zone when the body of the SCU is removed. Switching through the un-deployed and deployed positions is performed by changing the diameters of the downhole tools by inflating with a hardening substance. The system is controlled by a surface control system configured to directly and wirelessly communicate with a SCU wireless transceiver unit. The invention is aimed at reducing the costs associated with workover operations and related revenue losses.

Image from: US10570696B2

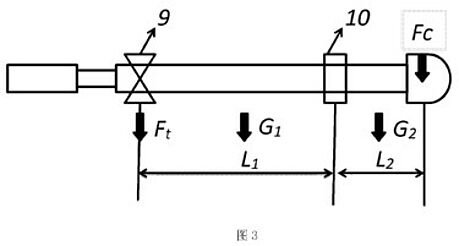

一种高效智能导向钻井系统及钻井方法 (en: Efficient intelligent guiding drilling system and drilling method) / P: CN112145071B / IPC: E21B7/00, E21B17/10, E21B47/022 / 刘永旺 / 中国石油大学(华东) / Appl. date: 31/08/2020; Publ. date: 01/02/2022 / National Intellectual Property Administration / Core document: CN112145071B / Claims: 7 / Rating: 17

An intelligent steering drilling system and drilling method are provided by the invention. The system includes an intelligent thrust applying tool that comprises a measuring module and a proofreading module and automatically measures well deviation and azimuth angle, compares them to designed values, and provides instructions to a thrust control module, which controls a pushing force of a thrust applying rib. The thrust applying rib has a telescopic function and applies downward thrust force to increase the deviation, upward pushing force to reduce the inclination, anticlockwise pushing force to increase the azimuth, and clockwise pushing force to lower the azimuth. The claims of the invention specify arrangement of the drilling system units and a set of steps to be performed in accordance with the method. Among the objects of the invention the authors mention improvement of the service life of the drilling system.

thrust applying tool that comprises a measuring module and a proofreading module and automatically measures well deviation and azimuth angle, compares them to designed values, and provides instructions to a thrust control module, which controls a pushing force of a thrust applying rib. The thrust applying rib has a telescopic function and applies downward thrust force to increase the deviation, upward pushing force to reduce the inclination, anticlockwise pushing force to increase the azimuth, and clockwise pushing force to lower the azimuth. The claims of the invention specify arrangement of the drilling system units and a set of steps to be performed in accordance with the method. Among the objects of the invention the authors mention improvement of the service life of the drilling system.

Image from: WO2022041679A1

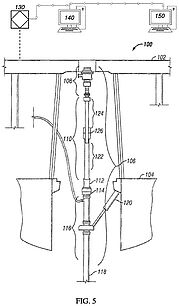

Intelligent RCD system / P: US10781657B2 / IPC: E21B33/08, E21B44/00, E21B3/02, E21B3/04 / Hardt Jesse Alan, Tarique Zaurayze, Couturier Yawan, Dow Blaine, Benson Walter, Kamps III Charles H / Schlumberger Technology Corporation / Appl. date: 22/08/2016; Publ. date: 22/09/2020 / United States Patent and Trademark Office / Core document: US10781657B2 / Claims: 20 / Rating: 15

A method of operating rotating control devices in downhole drilling is proposed in the patent. The method includes "…receiving a plurality of signals from a plurality of sensors into a programmable logic controller, the plurality of sensors provided on at least one component of a rotating control device assembly of a drilling system; providing measurement data from the plurality of signals using the programmable logic controller; processing the measurement data using a modeling software to determine at least one condition of the rotating control device assembly; and setting at least one limit into the programmable logic controller, where an alert is provided when measurement data is processed outside the at least one limit, wherein the at least one limit comprises a maximum pressure within a bearing package of the rotating control device assembly, and wherein the alert is provided when the measurement data comprises at least one pressure value within the bearing package that is greater than the maximum pressure." The inventors state that control method of the invention may indicate wear, failure, and fatigue of the system’s components, or presence of contaminants therein.

Image from: US10781657B2

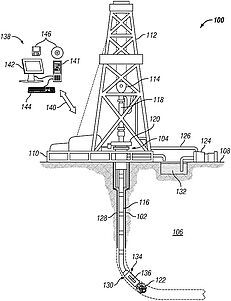

Systems and Methods Comprising Smart Auto Cleaning Pipe Screen for Drilling Operations / P: US10596496B2 / IPC: B01D29/60, B01D35/02, B01D29/01, B01D21/28, E21B21/06, B01D35/26, G05D7/06 / Sehsah Ossama, Costa de Oliveira Victor Carlos, Rivas Martinez Mario Augusto / Saudi Arabian Oil Compan / Appl. date: 19/10/2017; Publ. date: 24/03/2020 / United States Patent and Trademark Office / Core document: US10596496B2 / Claims: 20 / Rating: 17

The patent proposes an automated system and method for drilling fluid cleaning in drilling operations. The system comprises two flow lines with entrance and auto clean valves. The first line is equipped with pressure sensors in the inflow and outflow portions, and a controller, configured to "…determine the difference between the second pressure and the first pressure is above a predetermined threshold value; at least partially open the second entrance valve to divert drilling fluid intake from the first line to the second line; and close the first entrance valve to stop the drilling fluid from entering the first line." The auto cleaning system partially opens the first auto clean valve "…to divert the drilling fluid in the first line to the auto clean pump for removal of unwanted material from the drilling fluid." The claims of the invention describe types of valves used, number and types of lines involved, alert message-showing human machine interface, and working principles of the system. Among the problems of the invention the inventors mention cumbersome maintenance procedures of the prior-art solutions.

Image from: US10596496B2

Automated scheduling of sensors for directional drilling / A: WO2021236125A1 / IPC: E21B44/00, E21B47/02, E21B41/00, E21B7/06 / CHANPURA Reena Agarwal, ZALLUHOGLU Umut, SOSAREYES Cristian / Halliburton Energy Services, Inc. / Appl. date: 29/05/2020; Publ. date: 25/11/2021 / World Intellectual Property Organization / Core document: WO2021236125A1 / Claims: 20 / Rating: 11

A method and system for a rotary steerable system (RSS) employable in directional drilling operations are disclosed in the patent application. The RSS system comprises "…one or more sensors configured to take one or more measurements; and performing a tool position calculation from the one or more measurements; creating one or more event flags based at least in part on a location of the RSS in a formation, wherein the one or more event flags are created by an information handling system disposed on a bottom hole assembly; and selecting an algorithm for the tool position calculation based on the one or more event flags". In the system "…the tool position calculation determines toolface, inclination, or azimuth". The data collected by the information handling system is sent to the surface to be managed by personnel. According to the authors of the invention, this technology is aimed at facilitating the interpretation of failure-related data by an oil field personnel.

Image from: US20210363875A1

A complete version of the patent database Oil&Gas from Low Pemability Plays. Directional Drilling. August 2022 can be found at aenert.com.