In view of the looming energy crisis, scientists are leaving no stone unturned to find sustainable and efficient means to mitigate fossil fuel dependency. A promising source of energy is geothermal wells because, unlike wind or solar energy, they do not rely on the weather to produce heat or electricity. There are, however, some challenges which need to be tackled in order to enable wide adoption of geothermal energy. One of them is that the right combination of hot rock with underground water is not always readily available. Another problem pertains to the initial cost of drilling and well connecting.

Now (2022), a team of scientists at Sandia National Laboratory is conducting experiments to see if these challenges could be mitigated by using explosives and propellants. In an effort to find a new method of creating a geothermal fracture network, they are trying to make the process more efficient by reducing the amount of fluids having to be pumped down a well. For this reason, the scientists used 1-foot cubes of plexiglass, set off an explosion and listened to the formation of tiny fractures using specialised microphones. This information is then used to enhance existing computer models of underground explosions. Also, in order to recreate the conditions they would meet in hot and hard rock underground, the scientists put high pressure to the plexiglass to stress the material and see what effect it would have on the process. The team employed schlieren imaging, a process for photographing fluid flow, using ultra-high-speed cameras and mirrors to make out the differences in density when the waves went through the plexiglass, which were caused by the compression of a shock wave or differences in temperature. Another technique used in the experiment was photon Doppler velocimetry, measuring the speed of the shockwave when it approached the outside of the cube by detecting tiny changes to the frequency of a laser. The team hoped that this might enable them to study the weaker waves, but they only saw the initial shockwave. Therefore, they took specialised microphones, so-called acoustic emission sensors, placed them on the surface of the cube and were thus able to hear the weaker waves caused by fracture formation and triangulate where they were coming from within the cube. This enabled them to track when the fractures occurred, which was important for the ensuing computer modelling.

The scientists also conducted other experiments in cubes formed from different pieces of plexiglass which had been connected to mimic faults in rock in order to analyse what influence rock fault might have on the explosions. They found that fractures formed by explosions did not cross pre-existing fault-lines, but that the amount of stress the plexiglass was under and orientation of the rock fault were important.

One of the most important findings of the experiments was that fractures could start around the explosive or propellant, but would propagate towards the areas with less stress such as along existing fractures. This randomness was beneficial, the scientists believe, since it could be a possible means to connect pre-existing fractures into a network.

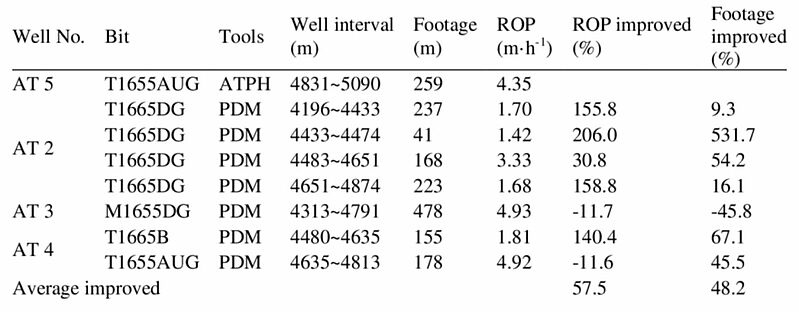

Scientists have long sought to enable wider harnessing of geothermal energy. In 2020, scientists tested an Axial & Torsional Percussion Hammer (ATPH) for drilling enhancement. ATPH was able to transform the kinetic energy of the drilling fluid into percussion load, and improve the rock-breaking efficiency of the bit. Since it had a mechanical seal design, it could drill efficiently at temperatures over 200°C, so that it can also be used in geothermal wells. The scientists chose the large eddy simulation (LES) method, a method of predicting turbulent flows, to calculate the percussion load characteristics of the ATPH oscillator, including its main frequency and amplitude. In the field drilling experiments of two high-temperature wells, ATPH had a better rate-of-penetration enhancement ability and longer working life. In the well interval drilled by ATPH, the maximum temperature at the well bottom reached 202.54°C.

Image: ROP comparison of test well AT5 with offset wells in the same block

Source: Heng Zhang, Shubin Liu, Hongjian Ni, Bin Huang/ An Axial and Torsional Percussion Hammer with Considerable Potential to Increase the Drilling Speed of High-Temperature Geothermal Wells/ IOP Conference Series Earth and Environmental Science 555(1):012131, August 2020/ DOI:10.1088/1755-1315/555/1/012131/ Open Source This article is licensed under a Creative Commons Attribution 3.0 Unported (CC BY 3.0)

Also in 2020, scientists conducted a research by means of experimental study, numerical simulation, and theoretical analysis in the granite reservoir of the Yangbajing geothermal field in Tibet. In the course of their study, the scientists based their experiments on the following: (a) physical experiment on granite specimen under high-temperature and high-pressure conditions to establish the deformation and failure laws of the borehole; (b) establishing rock heterogeneity using the Weibull distribution of the thermal expansion coefficient and reproduce the temperature and stress distribution of the borehole during physical experiment using the COMSOL software, which enabled them to analyse the distribution of the temperature field, stress field, and displacement field under thermo-mechanical coupling (TMC) condition; (c) analysing the failure laws of borehole under the TMC condition studying the temperature field and stress field, as well as the deformation and failure of granite specimen under high-temperature and high-pressure conditions, and the critical conditions of borehole instability during deep hole drilling of HDR. The scientists hoped that their research might have practical significance to the stability control of the surrounding rocks of borehole in relation to projects such as geothermal energy exploitation from HDR, deep oil and gas resource extraction, and deep hole drilling.

Image: A 3D model of granite specimen (Φ200 × 400mm) with a drill hole (41 mm diameter)

Source: Baoping Xi, Shuixin He, Yangchun Wu, Zepeng Chen/ Rheological deformation and failure laws of boreholes in granite under thermo-mechanical coupling and its application in deep hole drilling of hot dry rock for geothermal energy exploitation/ IOP Conference Series Earth and Environmental Science 570(3):032045, November 2020/ DOI:10.1088/1755-1315/570/3/032045/ Open Source This article is licensed under a Creative Commons Attribution 3.0 Unported (CC BY 3.0)

The experiments conducted using controlled explosions and propellants have several potential advantages for future geothermal energy production: they not only give the ample information on the propagation of the final cracks, but also recorded the series of events that led to their creation. Analysing this data will help refine existing models. These improved models, in turn, can lead to better results in lab experiments to be able to predict what might happen in actual geothermal field sites.

Currently, the team is carrying out experiments with explosives in 1-foot cubes of granite, with the eventual goal of conducting them in 3-foot cubes of granite. If these experiments are successful, the testing will be continued at the DOE’s Frontier Observatory for Research in Geothermal Energy. It would take three to five more years to reach field-scale testing and finally commercial implementation.