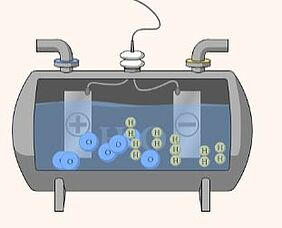

Photoelectrochemical (PEC) water splitting uses sunlight and photoelectrochemical materials to produce hydrogen from water. These photoelectrochemical materials help to directly split water molecules into hydrogen and oxygen. The semiconductor materials used in the process are similar to those used in photovoltaic solar electricity generation. The difference is that the semiconductor is kept in a water-based electrolyte and sunlight energises the water-splitting process. PEC reactors exist in panel form, as electrode systems or as slurry-based particle systems. So far, panel systems have received the greatest attention as they are similar to established photovoltaic panel technologies. Great improvements in the panel technology notwithstanding, PEC processes are still facing several problems concerning efficiency, durability, and cost.

Now (2021), Korean scientists from different institutions have joined forces to improve the performance of hematite photoanodes by employing germanium-tin co-doped systems, which allowed them to gain greater insight into the interaction between the tin (Sn) and the dopant. They hypothesized that unintentional Sn-doping from the fluorine-doped tin oxide (FTO) substrate, which was a result of the high-temperature annealing process, might have a negative impact on the system. Meanwhile, it is a known fact that thermal diffusion of Sn from the FTO substrate is one of the main factors in boosting PEC performance. Also, controlled Sn doping from the FTO substrate has been shown to improve the crystallinity of the hematite. Therefore, the scientists surmised that preventing the unintentional Sn-doping might further enhance the conversion efficiencies of the overall system. Having tried several substances, the scientists found that germanium (GE) was an even more efficient dopant than tin and designed a germanium-doping method which was able to control tin diffusion and significantly improve the hematite performance. After they had combined the photoanode with a perovskite solar cell, the tandem system achieved a solar-to-hydrogen conversion efficiency of 4.8%. The scientists used their findings to test them in a specifically designed photovoltaic device. For the photovoltaic device, FTO-coated glass as substrate was cleaned in an ultrasonic bath using detergents, acetone, and ethanol for 30 min, respectively.

The experiments and ensuing DFT calculations confirmed that Ge-doping by thermal diffusion of Ge in the GeO2 overlayer reduced the tin diffusion into the hematite lattice and created numerous oxygen evolution reaction active sites. Also, the research showed that Ge can lower the overpotential of the oxygen evolution reaction better than pure hematite.

For more than 10 years, scientists have tried to improve the photoelectrochemical water splitting process using perovskites. In 2011, for example, scientists designed ordered and vertically grown platinum (Pt)-doped α-hematite nanorod arrays on a gold substrate using the electrochemical co-deposition method with the help of an anodized aluminium oxide template. The elemental maps prepared by energy dispersive spectroscopy showed that the platinum was uniformly dispersed in the α-hematite nanorod arrays. The photoelectrochemical properties of the α-hematite/platinum composite nanorod arrays were researched by measuring their photocurrent-potential behaviour in a sodium hydroxide electrolyte with the help of AM 1.5 100 mW illumination. The scientists found that the Pt-doped α-hematite nanorod arrays showed an improved solar-to-hydrogen conversion efficiency for photoelectrochemical water splitting compared to undoped samples.

In 2016, scientists created a vertically grown hematite nanosheet film modified with silver nanoparticles and a cobalt−phosphate water oxidation cocatalyst which showed a remarkably high photocurrent density. The silver nanoparticles were responsible for significantly improved light harvesting and better charge transfer, while the cobalt−phosphate water oxidation cocatalyst enabled a highly stable oxygen evolution process. As a result, the photoelectrode design was a more efficient photoelectrochemical systems for solar-energy conversion.

In 2020, scientists designed a hybrid photoanode by growing a hematite film on silicon microwires. By means of introducing extrinsic (i.e., Sn) and intrinsic (i.e., oxygen vacancy) dopants, they brought about an increase in the photocurrent and a cathodical shift in the starting potential of the anode current together with a relatively high photocurrent at a low potential. Moreover, the relative concentration of the oxygen vacancies in the hematite was tuneable to suit individual installations.

The advantages of the new hematite anode are various: the morphology-controlled germanium-doped hematite with the reduced content of unintentionally doped tin was able to boost efficiencies by creating a high photocurrent density and a low turn-on voltage. Therefore, this research and co-doping strategy can potentially serve as a basic concept for the design of other electrodes and be further extended to various heteroatom-dopant systems (Ti, Sn, Si, Zr, and Ga) utilized in numerous applications, including solar conversion, sensing, and opto-ferroelectric devices which require doping for enhanced electrical conductivity.

This research presents the highest solar-to-hydrogen efficiency for a hematite photoanode-based tandem device and may eventually lead to a breakthrough in hematite photoelectrochemical cells whose development has been stagnant for many years.